6441-525D

8

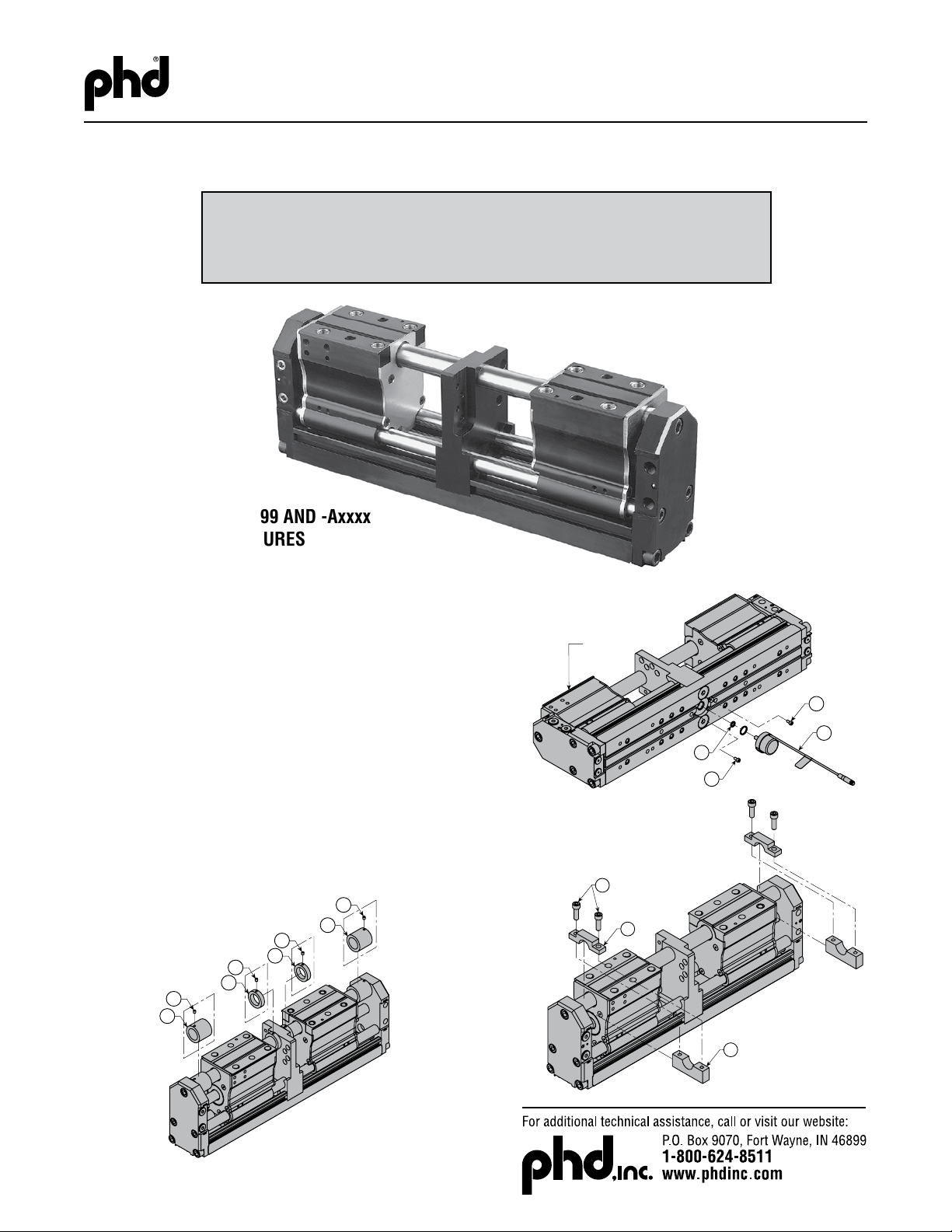

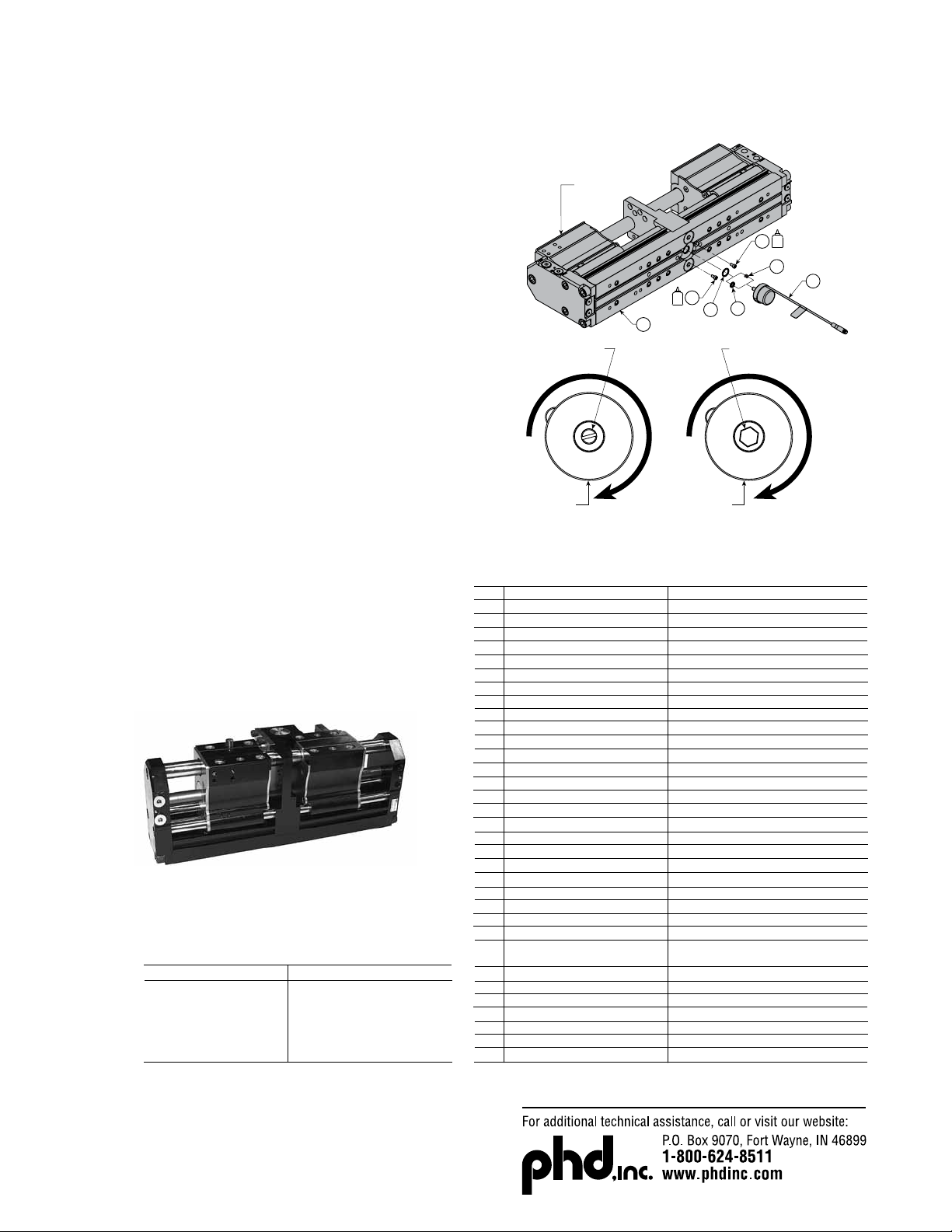

JAW POSITION SENSOR (SPP99 & STT99

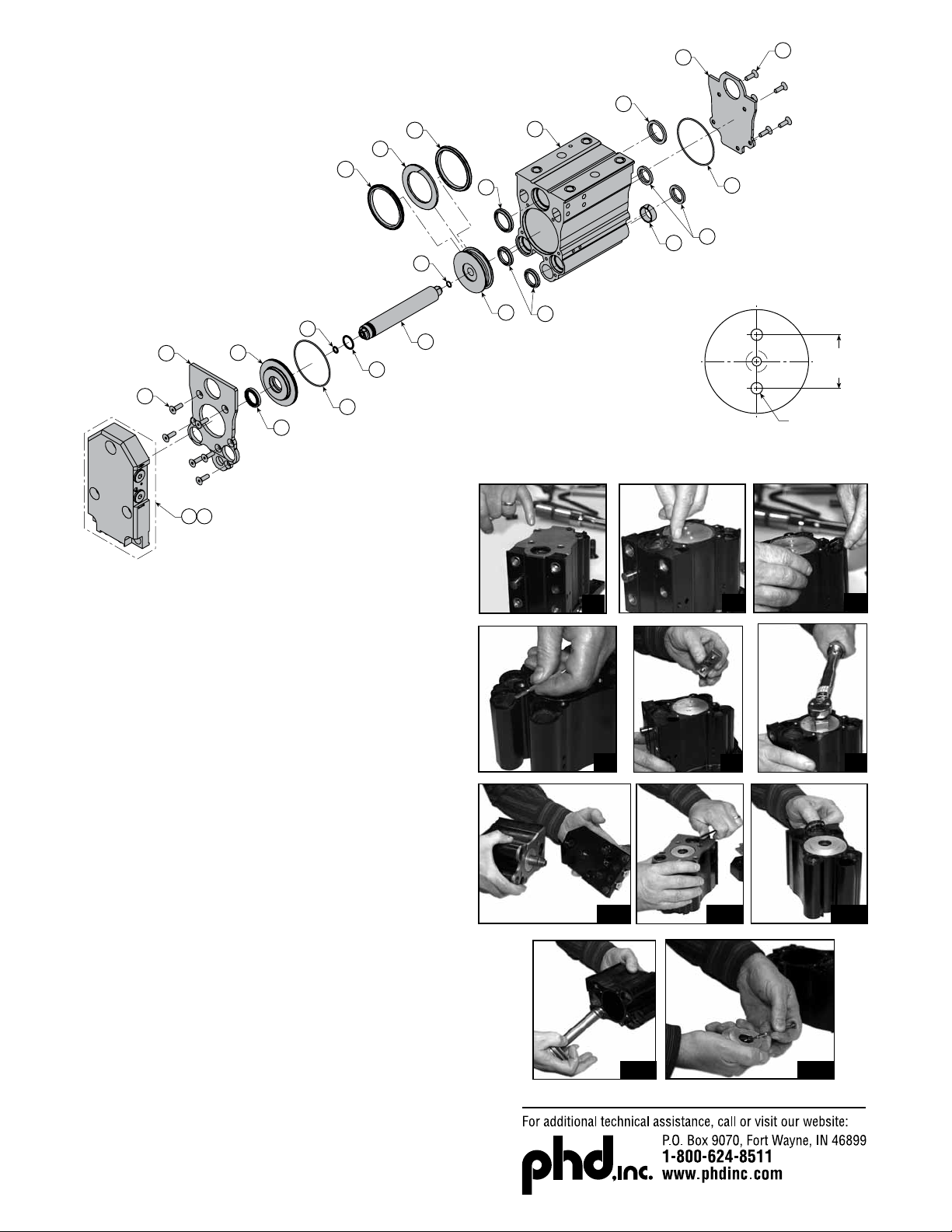

INSTALLATION (figure 18)

31) Move jaws to the full open position.

32) Insert o-ring seal (6) into shallow counterbore in base plate (1).

33) Looking at protruding shaft of sensor (30), rotate shaft clockwise

until rotation stops. See figure 18.

34) Visually align counterbores in base plate (1) and matching

notches in sensor or hexes (30).

Tip: To minimize voltage offset of sensor, position notches

in sensor slightly counter-clockwise of counterbores in base

plate. Then rotate body of the sensor clockwise to align

notches with counterbores in base plate AFTER the sensor has

been inserted into the base plate.

35) a. SPP99: Place end of sensor shaft against o-ring coupling (32)

in pinion and insert jaw position sensor into base plate (1).

Note: Initial resistance will be felt until sensor shaft completely

penetrates coupling o-ring allowing sensor to easily slide into

large counterbore in base plate.

b. STT99: Insert the spring (34) into the hex cutout in pinion,

then insert the jaw position sensor hex sleeve into hex cutout.

May need to rotate shaft to fit into hole hex. Only rotate as

much as needed to fit into hole.

36) Apply threadlocker to sensor cover fasteners, (8) install and

torque per TABLE 1.

Handcycletoverifyjawpositionsensorrotatesthroughthe

entirejawstroke.Ifsensorisnotinsertedcorrectly,sensor

could be damaged on STT99 sensor.

Cycle gripper a minimum of 10 times to ensure the offset voltage

output.

Note: Output voltage offset of sensor may have changed with

replacement of sensor. Check output with jaws in full open

position and adjust controller or setpoint module accordingly.

figure 18

JAW POSITION SENSOR REASSEMBLY

(-SPP99 & -STT99)

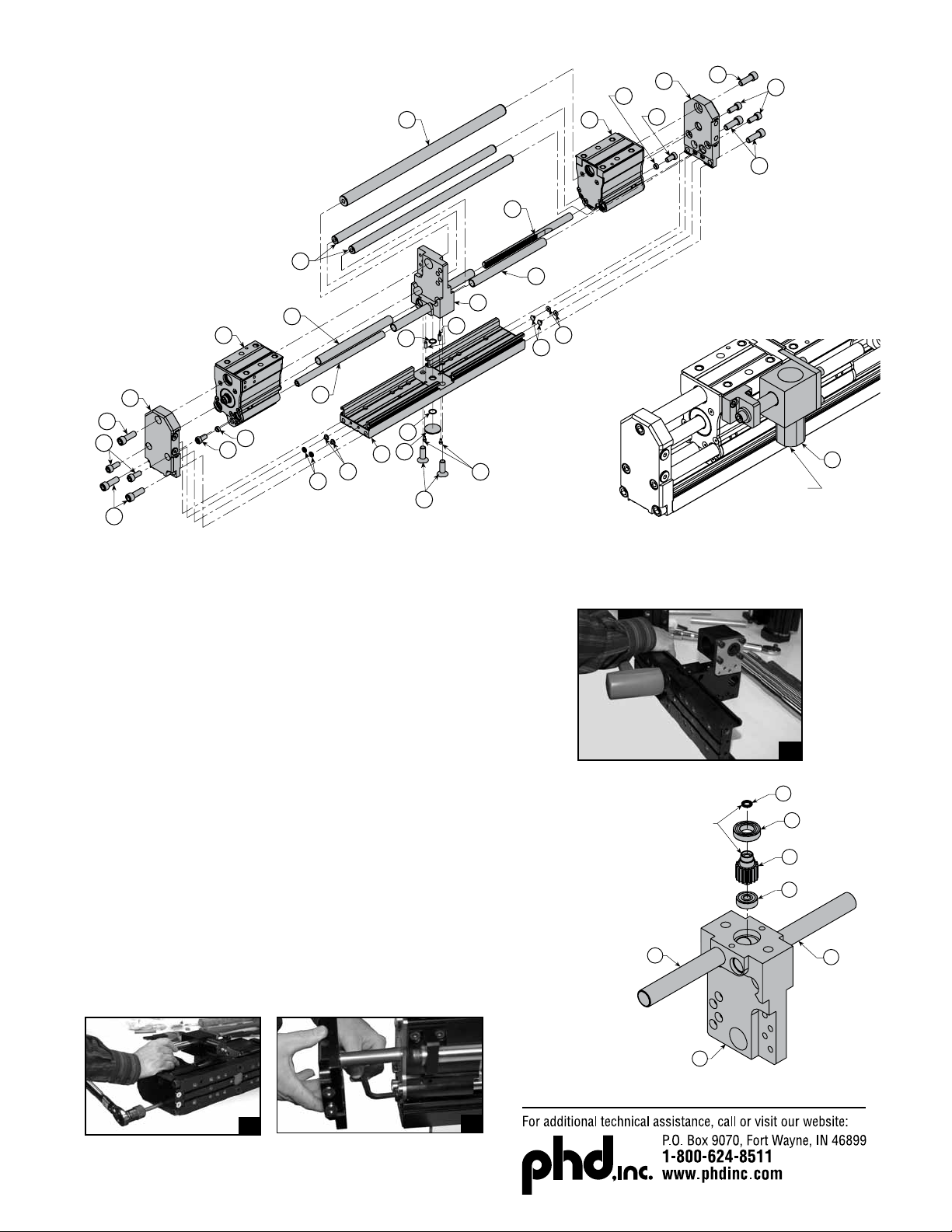

PART NUMBER CALLOUT FIGURE 4 AND 9

13

14

22

21

20

15

19

18

17

9

10

4

2

2

3

9

18

19

17

16

20

21

22

13 14

1

6

7

5

8

32

11

12

10

40

42

44

41 45

43

COMPLETE

RODLOK KIT

RODLOK ADAPTOR KIT

(MOUNTING ONLY)

RODLOK KIT

(LOCKING DEVICE ONLY)

25E

25

34

without

sensor

with

sensor

30

SPP99

STT99

KITS

Full unit description required -H6100

17831-095

Sold as part of seal kit only

Full unit description required -H4810

Full unit description required -H2000

Sold as part of seal kit only

74221

Full unit description required -H2040

Full unit description required -H3310

Full unit description required -H1300

Full unit description required -H4720

Full unit description required -H4710

Sold as part of seal kit only

74213

Full unit description required -H6210

Full unit description required -H6220

Full unit description required -H2605

75038

Full unit description required -H2020

Full unit description required -H4740

Full unit description required -H4740

Full unit description required -H2030

Full unit description required -H9110

Full unit description required -H9100

Sold as part of jaw position sensor kit

Sold as part

of sensor kit

Sold as part of sensor kit

Full unit description required -H1705

Full unit description required -H1715

Full unit description required -H1725

Full unit description required -H1735

Full unit description required -H1745

Full unit description required -H1755

PART DESCRIPTION

Base Plate Assembly

Dowel Pin

O-ring Seal

Center Plate Assembly

FHCS

O-ring Seal

Jaw Position Sensor Cover

SHCS

Rack

Rack Cover Tube

Large Jaw Guide

Small Jaw Guide

O-ring Seal

End Plate Communication Plug

End Plate Assembly (location 48)

End Plate Assembly (location 26)

Jaw Assembly

Rack Mounting Spacer

LHCS

SHCS

SHCS

SHCS

Complete Rodlok Kit (per jaw)

Rodlok Kit (per jaw)

Jaw Position Sensor Assembly

O-ring Sensor Coupling

(-SPP99 option only)

Spring - Sensor (-STT99 option only)

-ANxxx Travel Limiting Tube

-ATxxx Travel Limiting Tube

-APxxx Travel Limiting Tube

-AQxxx Travel Limiting Tube

-ARxxx Travel Limiting Tube

-AUxxx Travel Limiting Tube

PART NUMBER

KEY

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

25

25E

30

32

34

40

41

42

43

44

45

Note: All part numbers are for standard units. Options may affect part numbers.

*Seal kit does not include Rodlok seals. Rodlok seals sold in Rodlok seal kit only.

DESCRIPTION

Complete Rodlok Kit (per jaw)

Rodlok Kit (per jaw)

Rodlok Adaptor Kit (per jaw)

Rodlok Seal Kit (per jaw)

Seal Kit

Sensor Replacement Kit

PART NUMBER

Full unit description required -H9110

Full unit description required -H9100

Full unit description required -H9105

Full unit description required -H9115

Full unit description required -H9000

Full unit description required -H9305

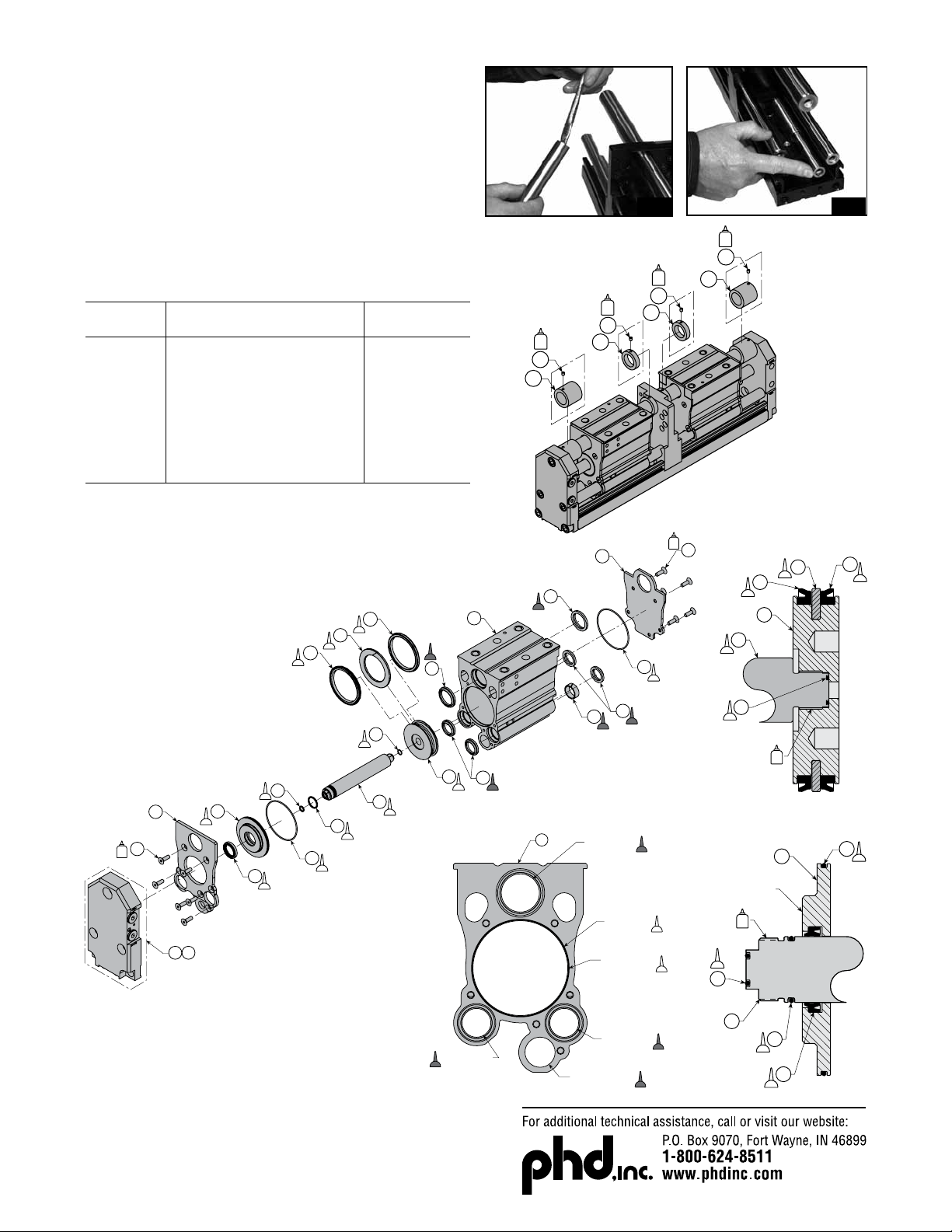

13

14

22

21

20

15

19

18

17

9

10

4

2

2

3

9

18

19

17

16

20

21

22

13 14

1

6

7

5

8

32

11

12

10

40

42

44

41 45

43

COMPLETE

RODLOK KIT

RODLOK ADAPTOR KIT

(MOUNTING ONLY)

RODLOK KIT

(LOCKING DEVICE ONLY)

25E

25

34

without

sensor

with

sensor

30

SPP99

STT99

KITS

Full unit description required -H6100

17831-095

Sold as part of seal kit only

Full unit description required -H4810

Full unit description required -H2000

Sold as part of seal kit only

74221

Full unit description required -H2040

Full unit description required -H3310

Full unit description required -H1300

Full unit description required -H4720

Full unit description required -H4710

Sold as part of seal kit only

74213

Full unit description required -H6210

Full unit description required -H6220

Full unit description required -H2605

75038

Full unit description required -H2020

Full unit description required -H4740

Full unit description required -H4740

Full unit description required -H2030

Full unit description required -H9110

Full unit description required -H9100

Sold as part of jaw position sensor kit

Sold as part

of sensor kit

Sold as part of sensor kit

Full unit description required -H1705

Full unit description required -H1715

Full unit description required -H1725

Full unit description required -H1735

Full unit description required -H1745

Full unit description required -H1755

PART DESCRIPTION

Base Plate Assembly

Dowel Pin

O-ring Seal

Center Plate Assembly

FHCS

O-ring Seal

Jaw Position Sensor Cover

SHCS

Rack

Rack Cover Tube

Large Jaw Guide

Small Jaw Guide

O-ring Seal

End Plate Communication Plug

End Plate Assembly (location 48)

End Plate Assembly (location 26)

Jaw Assembly

Rack Mounting Spacer

LHCS

SHCS

SHCS

SHCS

Complete Rodlok Kit (per jaw)

Rodlok Kit (per jaw)

Jaw Position Sensor Assembly

O-ring Sensor Coupling

(-SPP99 option only)

Spring - Sensor (-STT99 option only)

-ANxxx Travel Limiting Tube

-ATxxx Travel Limiting Tube

-APxxx Travel Limiting Tube

-AQxxx Travel Limiting Tube

-ARxxx Travel Limiting Tube

-AUxxx Travel Limiting Tube

PART NUMBER

KEY

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

25

25E

30

32

34

40

41

42

43

44

45

Note: All part numbers are for standard units. Options may affect part numbers.

*Seal kit does not include Rodlok seals. Rodlok seals sold in Rodlok seal kit only.

DESCRIPTION

Complete Rodlok Kit (per jaw)

Rodlok Kit (per jaw)

Rodlok Adaptor Kit (per jaw)

Rodlok Seal Kit (per jaw)

Seal Kit

Sensor Replacement Kit

PART NUMBER

Full unit description required -H9110

Full unit description required -H9100

Full unit description required -H9105

Full unit description required -H9115

Full unit description required -H9000

Full unit description required -H9305

JAW POSITION

SENSOR (30)

JAWS IN OPEN

POSITION

6

8

8

30

1

JAW POSITION

SENSOR (30)

OUTPUT SHAFT & HEX

SLEEVE ROTATE CLOCKWISE

UNTIL ROTATION STOPS

SPP99 STT99

OUTPUT SHAFT ROTATE

CLOCKWISE UNTIL

ROTATION STOPS

(STT99)

(SPP99)

32

34