Interpack ETII+ LD User manual

1

HSD2000 ET II

LD

OPERATION MANUAL & PARTS LISTS

2” (48mm) & 3” (72mm)

This Manual Covers Tape Heads with the Serial Numbers Starting with:

H178 or H678

For All Other Numbers, Please Contact Customer Service @ 800-474-827 (Menu #3)

USER MANUAL

ETII+ LD

For Serial Numbers:

H278 and H778 XX X XXX

REV 2 10122022

REV 2 10122022

UH178TW / UH678TW UDH178-01

2

REVISION CONTROL

REVISION CONTROL

REV00 Initial Release

REV01 Updated

UH178TW / UH678TW UDH178-01

3

TABLE OF CONTENTS

Section 1 HHHTUTUTUTable Of ContentsUUUTTTHHH---------------------------------------------------3

Section 2 HHHTUTUTUTechnical AssistanceUUUTTTHHH-----------------------------------------------4

Section 3 HHHTUTUTUWarrantyUUUTTTHHH---------------------------------------------------------------5

Section 4 HHHTUTUTUDescription Of Tape HeadUUUTTTHHH---------------------------------------- 6

Section 5 HHHTUTUTUSafety IssuesUUUTTTHHH--------------------------------------------------------- 7

Section 6 HHHTUTUTUSpecificationsUUUTTTHHH---------------------------------------------------------10

HHHTUTUTUTape Head DimensionsUUUTTTHHH--------------------------------------------10

HHHTUTUTUTape Head ComponentsUUUTTTHHH------------------------------------------ 11

HHHTUTUTUTape Head SpecificationsUUUTTTHHH-----------------------------------------12

Section 7 HHHTUTUTUSet Up ProceduresUUUTTTHHH--------------------------------------------------13

HHHTUTUTUMounting AdaptersUUUTTTHHH--------------------------------------------------14

HHHTUTUTUTape LoadingUUUTTTHHH---------------------------------------------------------15

HHHTUTUTUTape ThreadingUUUTTTHHH------------------------------------------------------16

HHHTUTUTUTape CenteringUUUTTTHHH------------------------------------------------------ 18

HHHTUTUTUTape Leg Length AdjustmentUUUTTTHHH-------------------------------------19

HHHTUTUTUOne Way Clutched Roller AdjustmentUUUTTTHHH------------------------- 20

HHHTUTUTUMain Spring AdjustmentUUUTTTHHH------------------------------------------- 20

HHHTUTUTUMandrel Tension AdjustmentUUUTTTHHH-------------------------------------21

Section 8 HHHTUTUTUTroubleshootingUUUTTTHHH------------------------------------------------------22

Section 9 HHHTUTUTURecommended Spare Parts ListUUUTTTHHH---------------------------------25

Section 10 HHHTUTUTUPreventive MaintenanceUUUTTTHHH-------------------------------------------27

HHHTUTUTUKnife Blade ReplacementUUUTTTHHH----------------------------------------- 27

HHHTUTUTUOiler Pad LubricationUUUTTTHHH----------------------------------------------- 28

HHHTUTUTUUrethane Wipe Down Roller ReplacementUUUTTTHHH------------------- 29

HHHTUTUTUSpring ReplacementsUUUTTTHHH---------------------------------------------- 30

HHHTUTUTUWipe Down Brush ReplacementUUUTTTHHH---------------------------------37

HHHTUTUTUSchedule Of Preventive MaintenanceUUUTTTHHH--------------------------38

Section 11 HHHTUTUTUAppendix A-Illustrations And Parts ListsUUUTTTHHH-----------------------39

UH178TW / UH678TW UDH178-01

4

TECHNICAL ASSISTANCE

Technical Support

This is the Interpack Model HSD 2000-ET II Series LD Tape Head you ordered. It has been

set up and tested in our factory with Intertape brand tapes. If any problems occur when setting

up or operating this equipment, please contact the authorized distributor from where you

purchased this item.

Should you need to contact Interpack Technical Support, please have the Tape

Head UUUmodel number and serial numberUUU available. This information can be found on the

nameplate of the side panel of the tape head. Interpack Technical Support is available during

normal business hours (Eastern Time).

UUUPHONEUUU 1-800-972-4675

If you have a technical question that does not require an immediate response, you may

contact Interpack by fax.

UUUFAXUUU 1-800-462-1293

Replacement Parts

Order parts by UUUitem numberUUU, UUUpart nameUUU and UUUquantity requiredUUU. Replacement parts are

only available from your Authorized Interpack Distributor exclusively.

Should you require assistance selecting the correct part, you may call:

Intertape Polymer Group

Interpack Machinery

9940 Currie Davis Drive, Suite 23B

Tampa, FL, 33619

Tel: 1-800-972-4675

Fax: 1-813-621-8449

MODEL:

SERIAL NUMBER:

DISTRIBUTOR PURCHASED FROM:

DATE OF PURCHASE:

UH178TW / UH678TW UDH178-01

5

WARRANTY

EQUIPMENT WARRANTY AND LIMITED REMEDY: The following warranty is made in lieu of all other

warranties, express or implied, including, but not limited to, the implied warranty of

merchantability, the implied warranty of fitness for a particular purpose, and any implied

warranty arising out of a course of dealing, a custom or usage of trade:

Intertape sells its Interpack Tape Heads, Case Tapers and Case Erectors with the following warranties:

1. The HSDPPP

PPP 2000 Tape Heads' knife blades, springs and wipe down rollers will be free from all

defects for a period of ninety (90) days.

2. All other HSDPPP

PPP 2000 Tape Head parts will be free from all defects for one (1) year after delivery.

3. Water Activated Tapers’ blades and brushes will be free from defects for ninety (90) days after

delivery

4. Drive Belts will be free from defects for ninety (90) days after delivery

5. The Gear Motors will be free from defects for one (1) year after delivery.

6. All other components will be free from defects for one (1) year after delivery.

If any part is proven defective within its warranty period, then the exclusive remedy and

Intertape's and the seller's sole obligation shall be, at Intertype’s option, to repair or replace

the part, provided the defective part is returned immediately to Intertape's factory or an

authorized service station designated by Intertape.

A part will be presumed to have become defective after its warranty period unless the part is

received or Intertape is notified of the problem no later than five (5) calendar days after the

warranty period.

If Intertape is unable to repair or replace the part within a reasonable time, then Intertape, at its

option, will replace the equipment or refund the purchase price. Intertape shall have no

obligation to install the repaired or replacement part.

Intertape shall have no obligation to provide or pay for the labor required to install the repaired

or replacement part. Intertape shall have no obligation to repair or replace (1) those parts

failing due to: operator misuse, carelessness, or due to any accidental cause other than

equipment failure, or (2) parts

1. Failure or damage is due to misapplication, lack of proper maintenance,

abuse, improper installation or abnormal conditions such as temperature,

moisture, dirt or corrosive matter, etc.

2. Failure due to inadequate cleaning, improper operating environment, improper

utilities or operator error.

3. Failure due to operations above the rated capacities, or in any other improper

manner, either intentional or otherwise.

4. Failure is due to equipment, which has been altered by anyone other than an

authorized representative of Intertape Polymer Group.

5. Failure is due to an attempt by the purchaser to correct alleged defective

equipment. In this event the purchaser is responsible for all expenses

incurred.

LIMITATION OF LIABILITY: Intertape and seller shall not be liable for direct, indirect, special,

incidental or consequential damages based upon breach of warranty, breach of contract,

negligence, strict liability or any other legal theory.

The foregoing Equipment Warranty and Limited Remedy and Limitation of Liability may be

changed only by written agreement signed by authorized officers of Intertape and seller.

UH178TW / UH678TW UDH178-01

6

D

ESCRIPTION OF

T

APE

H

EAD

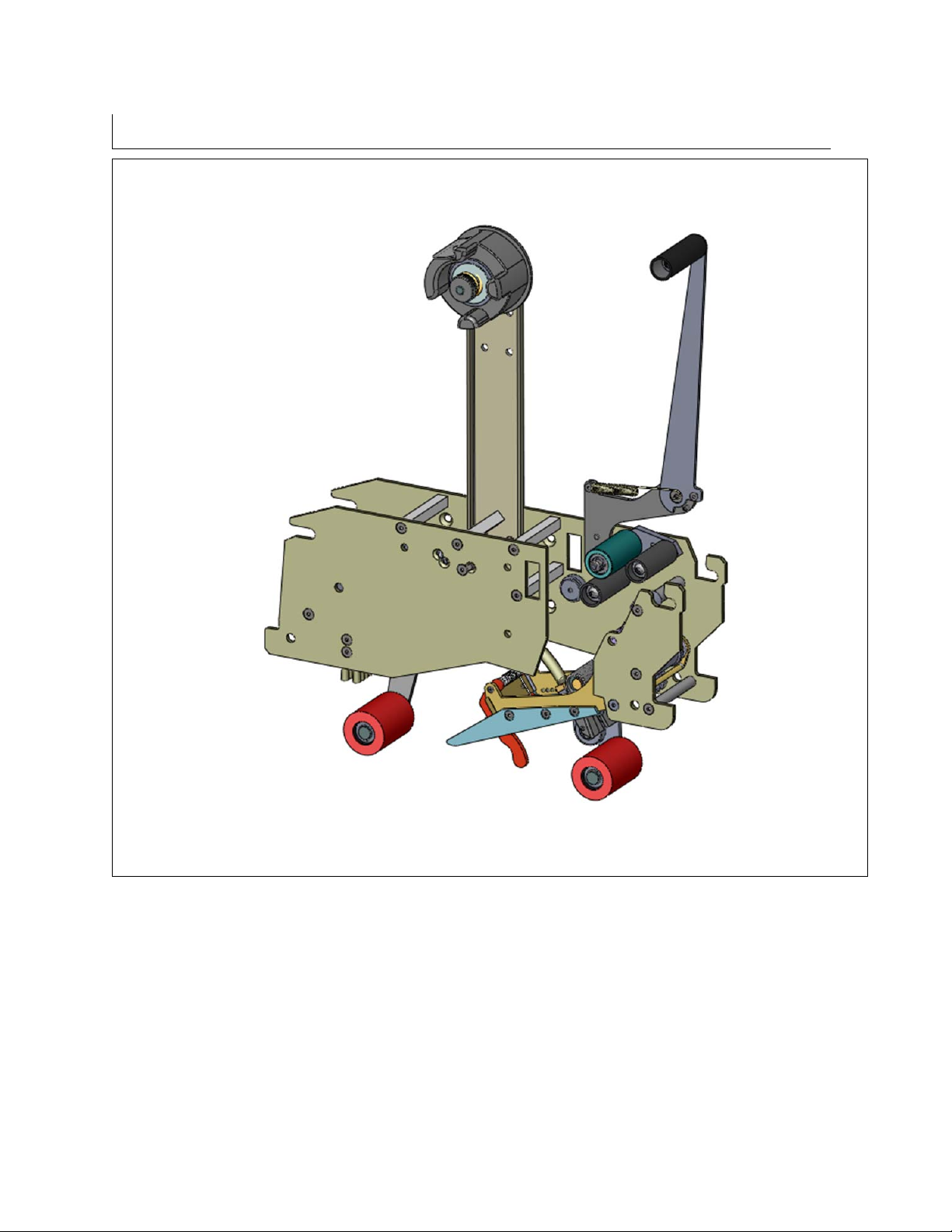

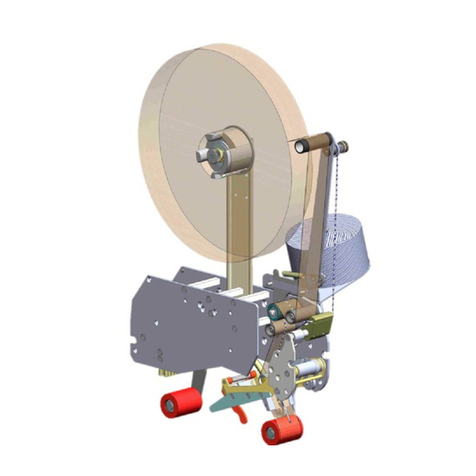

Figure 4-1

The Intertape HSD 2000-ET II Family of Tape Heads are designed to apply Intertape brand

pressure sensitive carton sealing tape to the top and bottom center seam of regular slotted

corrugated cartons.

This HSD 2000-ET II LD is designed to upgrade Little David® case sealers. No adapter kits

are needed to install this tape head into Little David® case sealers.

UH178TW / UH678TW UDH178-01

7

SAFETY ISSUES

There is a safety label used on all Interpack Tape Heads. This label is placed on the Tape

Head knife guard to warn operators and service personnel of the sharp cutting edge of the

blade. Please read the label and the following safety precautions before using the Tape Head.

Read this manual for other important safety operating and service information.

Only trained personnel are to operate and service Tape Head.

Wear safety glasses.

Shut off power to machine before adjusting.

Unplug electrical power before servicing.

All covers and guards must be in place before operating.

Stay clear of moving parts which can shear and cut.

Never operate the Tape Heads with the Knife Guard removed.

Turn electrical supply off before servicing the Tape Heads, including tape

loading and threading.

Note: Should any of the safety labels placed on the Tape Head be

damaged or destroyed, replacements are available.

UH178TW / UH678TW UDH178-01

8

S

AFETY

I

SSUES

The illustrated label shown in Figure 5-1 is

attached to the Knife Guard. The label

warns operators and service personnel of

the very sharp blade. The guard shall only

be removed when the torsion spring or the

guard itself is being replaced.

Should the tape head be operated without

blade guard, user voids all warranty

implied, the manufacturer bears no

responsibility for the consequences.

Tape head shall never be serviced while

mounted in a machine.

Figure 5-1

Label on Figure 5-2 is visible on carton

sealing machine.

Figure 5-2

While the tape head is processing cartons,

or it is in motion, keep your hands away

(Figure 5-3).

Figure 5-3

UH178TW / UH678TW UDH178-01

9

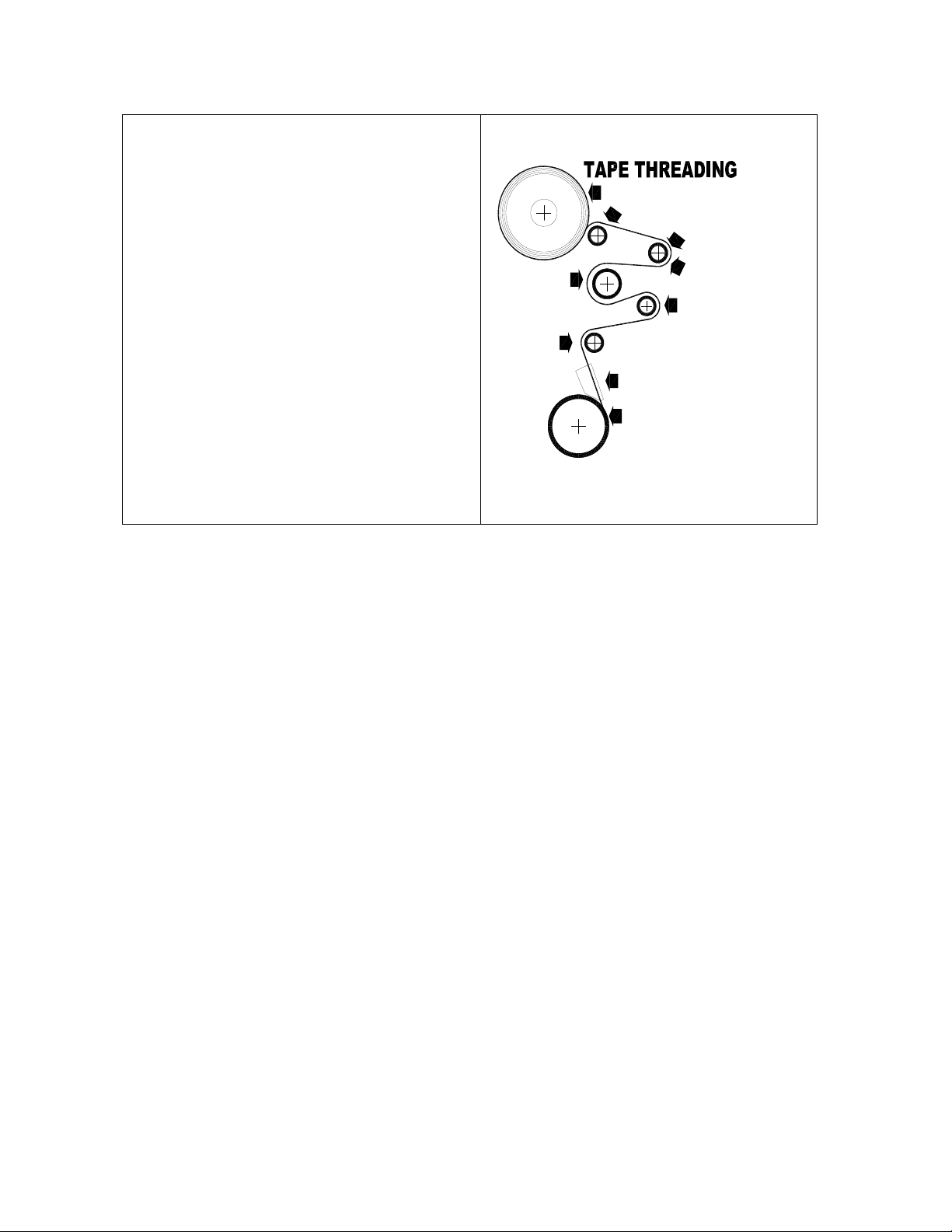

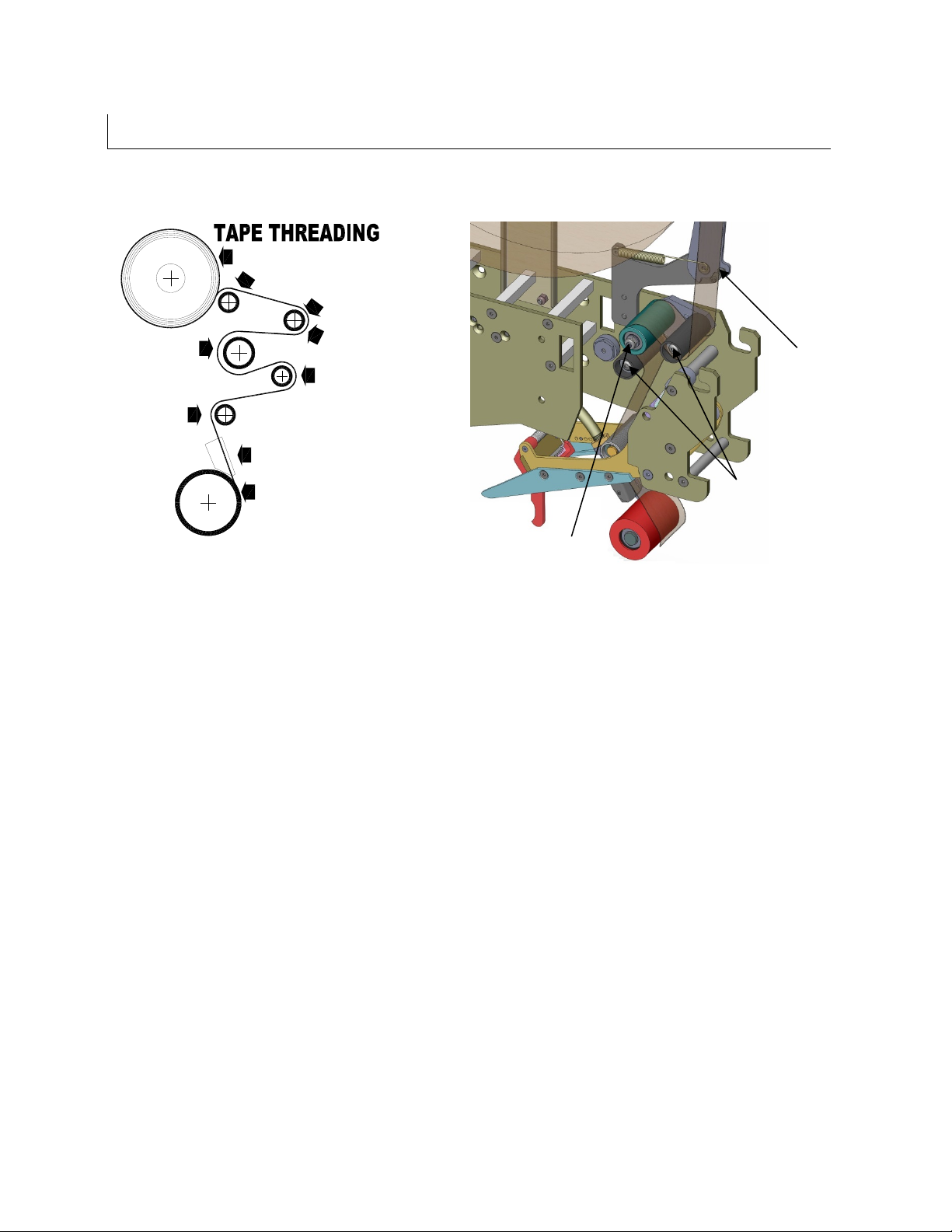

The illustrated label shown in Figure 5-4 is

attached to the operator side plate of each

tape head. The label provides operators

and service personnel the proper method of

threading a new roll of tape through the tape

head.

More detailed information is provided in the

“Set Up Procedures” portion of this manual.

Turn air and electrical supplies off before

servicing the tape heads.

ROLLER

GUIDE

ROLLER

CLUTCH

APPLICATION

TAPE GUIDE

ROLLER

SHOE

GUIDE

ROLLER

ADHESIVE SIDE

TAPE ROLL

GUIDE

ROLLER

PEEL OFF ROLLER

Figure 5-4

UH178TW / UH678TW UDH178-01

10

S

PECIFICATIONS

UUU

Tape Head Dimensions

Figure 6-1

UH178TW / UH678TW UDH178-01

11

S

PECIFICATIONS

UUU

Tape Head Components

Figure 6-2

UH178TW / UH678TW UDH178-01

12

SPECIFICATIONS

UUUOperating Conditions

Use in a dry, relatively clean environment at 40º to 105º F (5º to 40º C) with clean, dry cartons.

Note:

The HSD 2000-ET II LD Tape Head should UUUneverUUU be washed down or subjected to

conditions causing condensation on components. HSD 2000-ET II SS Stainless

Steel tape heads provide protection against mild detergent wash down only. Do

not subject Stainless Steel tape heads to ANY harsh detergent or solvent wash

down. The warrantee will be voided as a result.

UUUTape Head Specifications

1) General

Use Intertape brand Pressure Sensitive Carton Sealing Tape.

2) Tape Width

For HSD 2000-ET II 2” (48mm) models

1 ½ to 2 inch wide tape (36 to 48 mm)

For HSD 2000-ET II 3” (72mm) models

2 ½ to 3 inch wide tape (60 to 72mm)

3) Tape Roll Diameter

Maximum of 16 inches (405 mm) on a 3-inch (76.86 mm) diameter core.

(Accommodates all Intertape brand film tape machine roll lengths)

4) Tape Application Leg Length – Standard

2 ¼ inches (+0.25", -0")

57.15 mm, (+6.3 mm, -0 mm)

5) Tape Application Leg Length – Optional

The tape leg length can be adjusted from:

1 7/8 to 2 3/4 inches

47.8 mm to 69.9 mm

6) Tape Head Weight

The Tape Head weighs 21 lbs. (9.5 kg.) packaged.

7) Operating Speed

For use with line speeds up to 90 ft./min maximum.

UUUPLEASE NOTEUUU: A stronger main spring may be necessary to process cases at

90 ft./ min. Void filled cases should not be processed with the stronger main

spring.

UH178TW / UH678TW UDH178-01

13

SET-UP PROCEDURES

UUUReceiving and Handling

All contents must be verified upon reception. The following items are included with each tape

head.

DESCRIPTION UH 178TW

2” WIDE

PLATED

UH 678TW

3” WIDE

PLATED

Main Tape Head assembly 1 1

Main spring (part no. UPH1090) 1 1

Main spring (part no. UPH0910 1 1

Knife arm spring (part no. UPH4665) 1 1

Operational manual & parts list 1 1

Note: After unpacking the Tape Head, look for any damage that may have

occurred during shipping. Should the Tape Head be damaged, file a claim

with the transport company and notify your Intertape representative.

UH178TW / UH678TW UDH178-01

14

S

ET

-U

P

P

ROCEDURES

WARNING! TURN OFF ELECTRICAL POWER SUPPLY AND DISCONNECT THE POWER CORD

FROM THE ELECTRICAL SUPPLY BEFORE BEGINNING TO WORK ON THE TAPE

HEADS OR TO LOAD TAPE.IF POWER CORDS ARE NOT DISCONNECTED,

SEVERE INJURY TO PERSONNEL COULD RESULT.

UUU

Mounting Adapters

HSD 2000-ET II LD Tape Heads are designed to be installed on Little David® case sealers. If

your Tape Heads are to be installed on a different case sealer or case erector, please review

these general guidelines plus any additional instructions included with your HSD 2000-ET II

LD tape head.

Location Of Mounting Adapter Holes

Front Cover

Figure 7-1

Rear Cover

Figure 7-

2

Examples Of Mounting Hardware

There are numerous mounting holes on the

front and rear side plates of the tape head.

These are used to install various mounting

adaptors. Examples of these mounting

adapters are:

1. Internal and external threaded nuts

2. Mounting Bars

3. Threaded Spacers

Figure 7-3

UH178TW / UH678TW UDH178-01

15

S

ET

-U

P

P

ROCEDURES

UUU

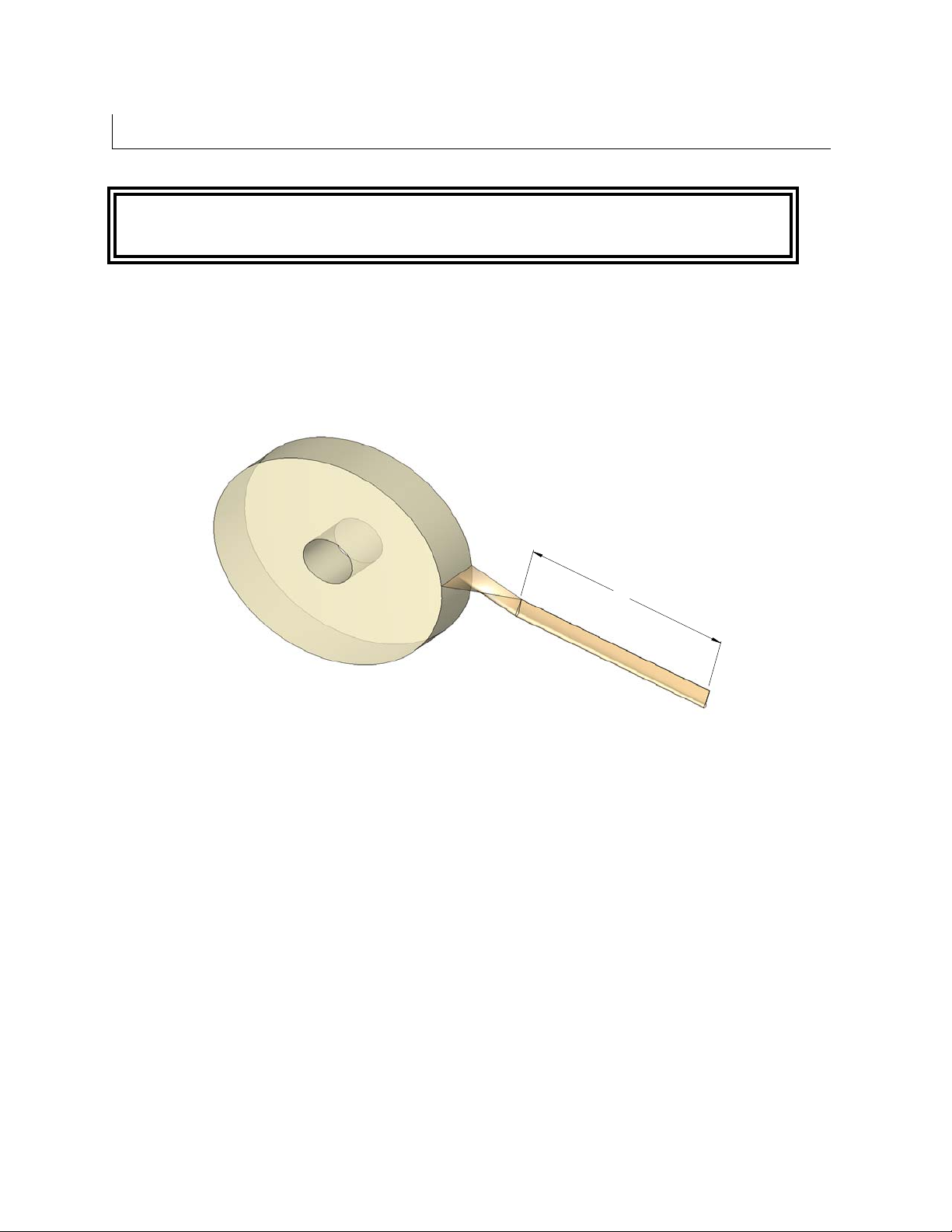

Tape Loading

The HSD 2000-ET II LD Tape Heads accommodate 2-inch (48mm) wide tape rolls, while the

HSD 2000-ET II/3" LD Tape Heads accommodate 3-inch (72mm) wide rolls.

1. Place the tape head onto a sturdy, flat surface.

2. Move the peel off roller away from the mandrel.

3. Push the roll of tape onto the mandrel with the adhesive side up (refer to

Threading Diagram under Tape Threading section in this manual) until the core

seats against the mandrel flange. This ensures the tape will be aligned when

feeding into the tape head.

4. Replace the peel roller against the tape roll.

Figure 7-4

Adhesive Side

Peel Off Roller

Tape Roll

UH178TW / UH678TW UDH178-01

16

SET-UP PROCEDURES

WARNING! THE KNIFE CONTAINED IN THE TAPE HEAD IS EXTREMELY SHARP.USE CAUTION

WHEN REMOVING THE BLADE GUARD AND THREADING THE TAPE TO AVOID

PERSONNEL INJURY.

Tape Threading Preparation

Figure 7-5

Threading the tape in the Tape Head does not require any special tools.

1. Pull approximately twelve (12) inches of tape from the roll and fold in half

lengthwise, adhesive side to adhesive side. This allows you to thread the tape

without it adhering to the guide and clutch rollers inside the Tape Head.

12

UH178TW / UH678TW UDH178-01

17

SET-UP PROCEDURES

Figure 7-6

Figure 7-7

1. As illustrated in Figures 7-6 & 7-7, first thread the tape tail over the Peel Off

Roller.

2. Thread the tape over and around the first “smooth” Guide Roller.

3. Continue to thread the tape over and around the “knurled” Clutch Roller.

4. Then pass the tape up and over the second “smooth” Guide Roller.

5. Continue threading the tape over and behind the final “knurled” Guide Roller.

6. Thread the tape through the cut-out provided in the Tape Guide Shoe and pull the

tape through the front Application Roller, ensuring that the tape is retained in the

tape guide shoe

7. Cut off the folded tape.

8. Replace the Tape Head to its initial position in the machine.

ROLLER

GUIDE

ROLLER

CLUTCH

APPLICATION

TAPE GUIDE

ROLLER

SHOE

GUIDE

ROLLER

ADHESIVE SIDE

TAPE ROLL

GUIDE

ROLLER

PEEL OFF ROLLER

Adhesive Side

Guide Roller

Clutch Roller

UH178TW / UH678TW UDH178-01

18

SET-UP PROCEDURES

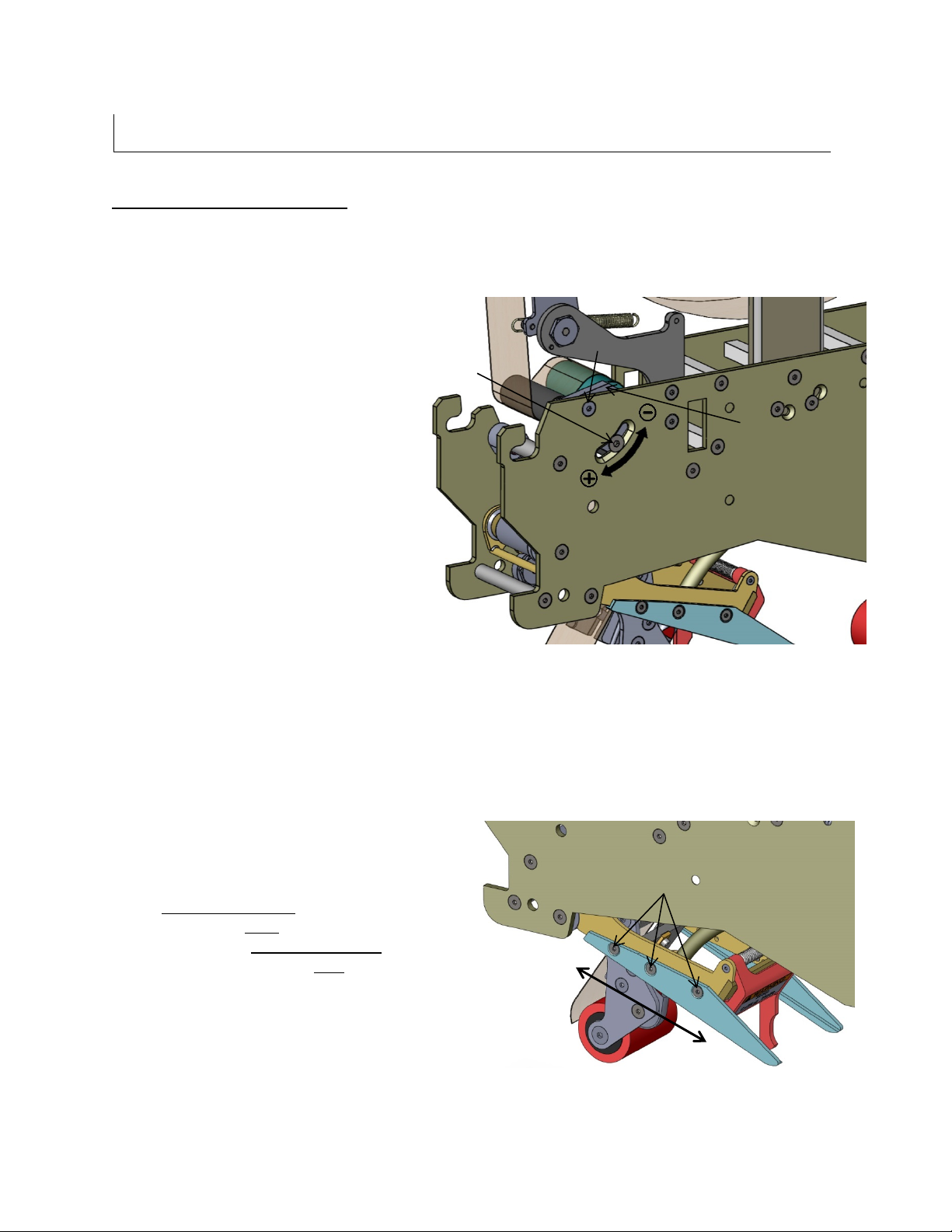

UUUTape Centering

If the tape is not centered as it travels through the tape shoe guide, the tape mandrel can be

adjusted in or out to correct this

Loosen the M18 inverse jam nut on the

rear of the mandrel as shown in Figure

7-8 with a 10 mm Allen key.

Figure 7-8

Adjust the shaft in or out as required

using a flat screwdriver as illustrated in

Figure 7-9. When the tape is

centered, tighten the jam nut .

Figure 7-9

UH178TW / UH678TW UDH178-01

19

SET-UP PROCEDURES

UUUTape Leg Length Adjustment

For optimum performance, the tape leg length has been factory set at 2 inches (50 mm).

However, the tape leg length can be modified.

Front Tape Leg

To adjust the tape leg length on the

leading end of the box, refer to

Figure 7-12 of the clutch assembly.

Facing the rear main frame, loosen

the two (2) Flat Head Cap Screws

using a 3 & 4 mm hexagonal key.

Rotate the clutch assembly to bring

the lowers screw towards the minus

(-) sign stamped on the rear plate for

a shorter tape leg. Conversely, bring

the bottom screw towards the plus

(+) sign for a longer tape leg.

Re-tighten both Flat Head Cap

Screws.

Figure 7-10

Rear Tape Leg

To adjust the tape leg length on the trailing

end of the box, both chrome knife arm

extension brackets must be re-positioned.

Unscrew the three (3) Flat Head Cap

Screws on each knife arm extension using

a 2.5 mm hexagonal key.

For a UUUShorter Tape LegUUU, bring the knife

arm towards the UUUfrontUUU of the tape head.

Conversely, for a UUULonger Tape LegUUU, bring

the knife arm towards the UUUrearUUU of the tape

head.

Replace the three (3) screws on each

knife arm extension and tighten.

Figure 7-11

Front

Rear

M6 M5

CLUTCH

ASSEMBLY

M4

UH178TW / UH678TW UDH178-01

20

SET-UP PROCEDURES

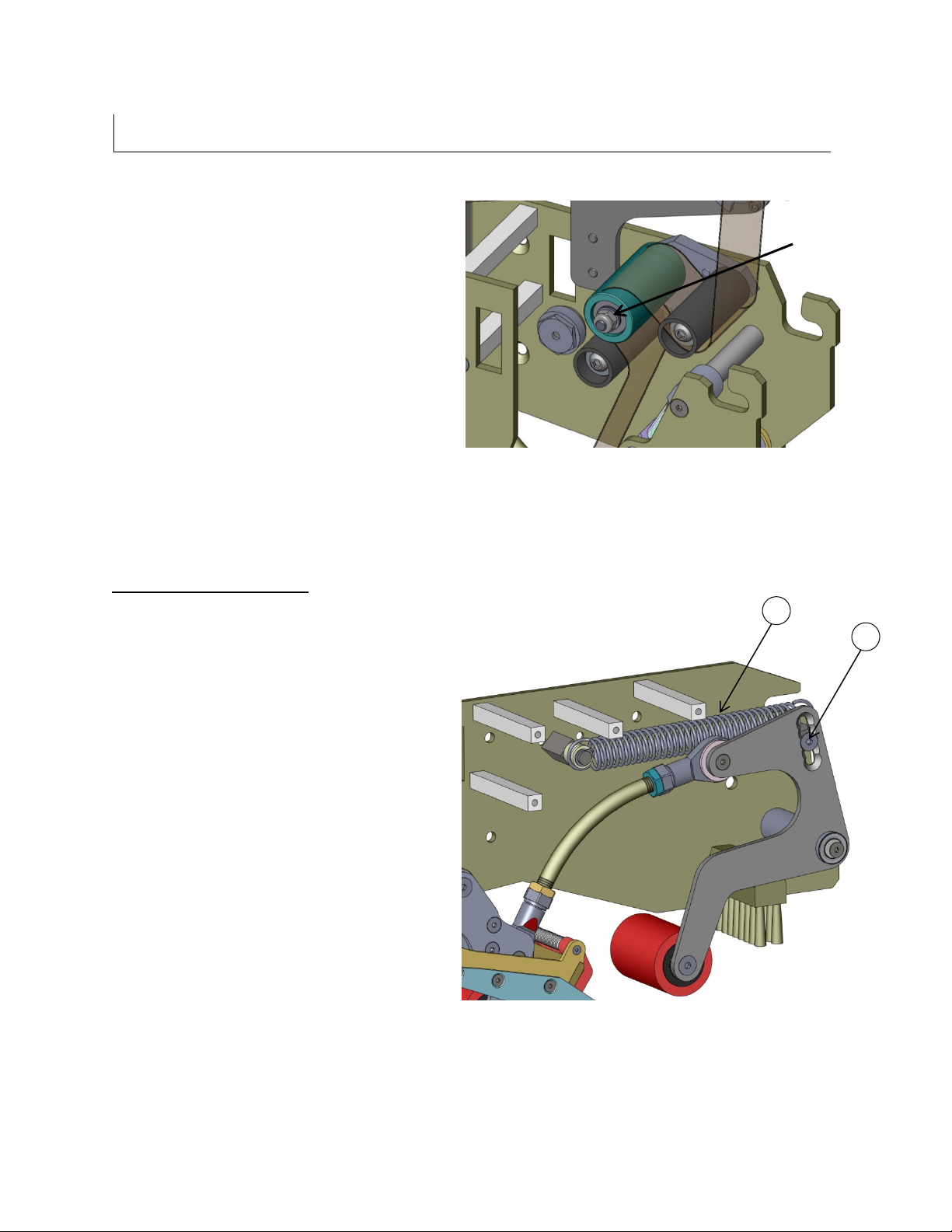

One Way Clutched Roller Adjustment

This one direction, tensionable roller

assures that proper tension is present when

cutting the tape. It is preset at the factory

but should re-adjustment be necessary,

follow these steps:

1. Decrease all mandrel tension

2. Decrease all one way clutched roller

tension

3. Process a case through the

machine. It should not cut tape.

4. Gradually, apply a very small amount

of tension to the one way clutched

roller until a the tape is cleanly cut as

the case processes

5. Too much tension will cause the tape

to wrinkle or snap back

6. Too little tension will not cut the tape.

Figure 7-12

UUUMain Spring Adjustment

The main spring tension is set at the factory.

This setting should be optimal for most

applications. Environments where a

different setting is desirable would be:

1. Void filled cases would need a lighter

wipe down pressure

2. Overfilled cases might require additional

wipe down pressure

3. Double wall corrugated might need

additional wipe down pressure to

overcome the memory of the major flaps.

4. Thinner walled corrugated cases might

require less wipe down pressure

5. Faster line speeds would need additional

spring tension to provide a quicker wipe

down of the rear tape leg.

Should the need arise to increase or

decrease the wipe down pressure, follow

these steps:

1. Remove main spring (Item #1)

2. Loosen the flathead countersink

screw (Item # 2)

3. Relocate to the higher hole to

decrease force or to a lower hole to

increase force.

Figure 7-13

Nylon

Lock

Nut

1 2

Table of contents

Other Interpack Industrial Equipment manuals

Interpack

Interpack RSA 20-B User manual

Interpack

Interpack USA 2024-SB User manual

Interpack

Interpack ipg RSA 2625-TB User manual

Interpack

Interpack HSD2000 XS II Series User manual

Interpack

Interpack CE-12P User manual

Interpack

Interpack CE-12P User manual

Interpack

Interpack HSD2000 ET II RC User manual

Interpack

Interpack USA 2024-SB DH User manual