Interroll DP 0080 User manual

INSPIRED BY EFFICIENCY

User Manual

Interroll Pallet Drive

DP 0080

DP 0089

Manufacturer

Interroll Trommelmotoren GmbH Interroll (Suzhou) Co. Ltd.

Opelstr. 3 No.16 Huipu Road

41836 Hueckelhoven/Baal Suzhou Industrial Park, Jiangsu

Germany Province 215126, Suzhou

Phone: +49 2433 44 610 China

www.interroll.com www.interroll-group.cn

Contents

We strive for the information presented to be correct, up to date and complete. We have carefully worked out the

contents of this document. However, we assume no liability for the information. We expressly deny any liability for

damages or consequential damages that are connected in any form with the use of this document. We reserve the

right to change the documented products and product information at any time.

Copyright / intellectual property right

Texts, images, graphics and the like as well as their arrangement are protected by copyright and other protection

laws. Reproduction, modication, transfer or publication of any part or the entire content of the document in any

form is prohibited. This document is intended exclusively for information purposes and for intended use and does not

authorize replicating the respective products. All signs contained in this document (registered trademarks, such as

logos and business designations) are the property of Interroll Trommelmotoren GmbH or third parties and may not be

used, copied or distributed without prior written consent.

Version 1.2 (08/2022) en

Translation of original operating instructions 3 of 40

Table of Contents

1 Introduction 5

1.1 Information about the operating instructions.....................................................................................................................5

1.1.1 Contents..................................................................................................................................................................5

1.1.2 The instruction manual is part of the product ..............................................................................................5

1.2 Warning notices in this manual..............................................................................................................................................5

2 Safety 6

2.1 State of the art...........................................................................................................................................................................6

2.2 Intended use................................................................................................................................................................................6

2.3 Unintended use...........................................................................................................................................................................6

2.4 Personnelqualication..............................................................................................................................................................6

2.5 Dangers........................................................................................................................................................................................7

2.6 Interfaces to other devices......................................................................................................................................................8

3 Product information 9

3.1 Product description....................................................................................................................................................................9

3.1.1 Options...................................................................................................................................................................9

3.2 Thermal protection....................................................................................................................................................................9

3.3 Type plate of Pallet Drive..................................................................................................................................................... 10

3.4 Productidentication............................................................................................................................................................. 12

3.5 Technical data.......................................................................................................................................................................... 12

3.6 Electrical data.......................................................................................................................................................................... 13

3.6.1 DP 0080 3-phase and DP 0089 3-phase.................................................................................................. 13

3.7 Dimensions................................................................................................................................................................................ 13

4 Options and accessories 15

4.1 Electromagnetic brake for the Pallet Drive...................................................................................................................... 15

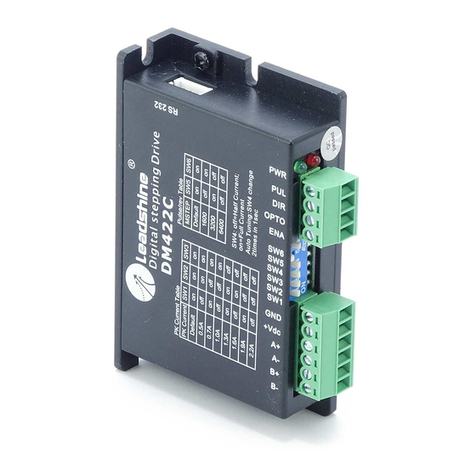

4.2 Asynchronous Pallet Drive with frequency inverters ..................................................................................................... 16

4.2.1 Torque dependent on input frequency........................................................................................................ 16

4.2.2 Frequency inverter parameters..................................................................................................................... 16

5 Transport and storage 18

5.1 Transport ................................................................................................................................................................................... 18

5.2 Storage...................................................................................................................................................................................... 18

6 Assembly and installation 19

6.1 Warning notices concerning the installation ................................................................................................................... 19

6.2 Installing the Pallet Drive....................................................................................................................................................... 19

6.2.1 Positioning the Pallet Drive.............................................................................................................................. 19

6.2.2 Installation of Pallet Drive in mounting brackets....................................................................................... 20

6.3 Warning notices concerning the electrical installation ................................................................................................. 21

6.4 Electrical connection of the Pallet Drive............................................................................................................................ 21

6.4.1 Connection of the Pallet Drive - with cable ............................................................................................... 21

6.4.2 Connection diagrams....................................................................................................................................... 21

4 of 40

Version 1.2 (08/2022) en

Translation of original operating instructions

Table of Contents

6.4.3 External motor protection............................................................................................................................... 23

6.4.4 Integrated thermal protection ....................................................................................................................... 23

6.4.5 Frequency inverter............................................................................................................................................ 23

6.4.6 Electromagnetic brake .................................................................................................................................... 24

7 Initial startup and operation 25

7.1 Initial startup ............................................................................................................................................................................ 25

7.1.1 Checks before the initial startup................................................................................................................... 25

7.2 Operation................................................................................................................................................................................. 25

7.2.1 Checks before every startup.......................................................................................................................... 26

7.3 Procedure in case of accident or fault.............................................................................................................................. 26

8 Maintenance and cleaning 27

8.1 Warning notices concerning maintenance and cleaning............................................................................................. 27

8.2 Preparation for maintenance and cleaning by hand....................................................................................................27

8.3 Maintenance ............................................................................................................................................................................ 27

8.3.1 Checking the Pallet Drive................................................................................................................................ 27

8.4 Cleaning.................................................................................................................................................................................... 27

9 Troubleshooting 28

10 Decommissioning and disposal 32

10.1 Shutdown.................................................................................................................................................................................. 32

10.2 Disposal..................................................................................................................................................................................... 32

11 Appendix 33

11.1 List of abbreviations............................................................................................................................................................... 33

11.2 Translation of the original Declaration of Conformity.................................................................................................. 36

11.3 UKCA Declaration of Conformity ...................................................................................................................................... 37

Version 1.2 (08/2022) en

Translation of original operating instructions 5 of 40

Introduction

1 Introduction

1.1 Information about the operating instructions

The following Pallet Drive types are described in these operating instructions:

• DP 0080

• DP 0089

1.1.1 Contents

This instruction manual contains important notes and information about the various operating phases of the Pallet

Drive.

The instruction manual describes the Pallet Drive as it is delivered by Interroll.

In addition to this instruction manual, special contractual agreements and technical documents apply to special

versions.

1.1.2 The instruction manual is part of the product

• Fortrouble-free,safeoperationandwarrantyclaims,readtheinstructionmanualrstandfollowtheinstructions.

• Keep the instruction manual close to the Pallet Drive.

• Pass the instruction manual on to any subsequent operator or occupant.

• NOTICE! The manufacturer does not accept any liability for faults or defects due to non-observance of this

instruction manual.

• If you still have questions after reading the instruction manual, please contact Interroll customer service. Contact

persons close to you can be found on the Internet under www.interroll.com/contact.

1.2 Warning notices in this manual

The warning notices refer to risks that may arise while using the Pallet Drive. They are available at four danger levels

with the following signal words:

DANGER

Identiesadangerwithhighriskthatwillresultindeathorseriousinjuryifitisnotavoided.

WARNING

Identiesadangerwithmediumriskthatcouldresultindeathorseriousinjuryifitisnotavoided.

CAUTION

Identiesadangerwithlowriskthatcouldresultinminorormediuminjuryifitisnotavoided.

NOTICE

Identiesadangerthatresultsinpropertydamage.

6 of 40

Version 1.2 (08/2022) en

Translation of original operating instructions

Safety

2 Safety

2.1 State of the art

The conveyor is designed according to the state of the art and is reliable in operation, once distributed. However, risks

may still arise.

Disregardingthenoticesinthismanualmayleadtoseriousinjury.

• Carefully read the manual and follow its content.

• Observe local accident prevention regulations and general safety regulations that apply in the area of use.

2.2 Intended use

The Pallet Drive is intended for use in industrial environments, super markets and airports and is used for the transport

of unit handling, such as pallets, cartons or crates. The Pallet Drive must be integrated into a conveyor module or

conveyor system. Any other use is considered inappropriate.

UseofthePalletDriveisonlyallowedintheareasdescribedintheproductinformationchapter.Anymodications

thataectthesafetyoftheproductarenotpermitted.

ThePalletDrivemayonlybeoperatedwithinthedenedoperatinglimits.

2.3 Unintended use

The Pallet Drive must not be used for transporting people.

The Pallet Drive is not intended for use under impact or shock loads.

ThePalletDriveisnotdesignedtobeusedunderwater.Suchauseleadstopersonalorfatalinjuriesfrom

electrocution as well as the penetration of water, resulting in a short circuit or motor damage.

The Pallet Drive may not be used as a drive for cranes or lifting devices or for the corresponding hoist ropes, cables or

chains.

UseofthePalletDriveforanythingotherthantheintendedpurposeissubjecttoapprovalbyInterroll.

Unlessotherwisestatedinwritingand/orspeciedinaquote,Interrollanditsdealersshallassumenoliabilityfor

productdamageorfailurewhichresultfromfailuretoobservethesespecicationandrestrictions(seethechapter

„Electrical data” of the respective series).

2.4 Personnel qualication

Unqualiedpersonnelcannotrecognizerisksand,asaresult,issubjecttogreaterdangers.

• Authorizeonlyqualiedpersonneltoperformtheactivitiesdescribedintheseinstructions.

• The operating company must ensure that personnel follow locally applicable regulations and rules about safety and

hazardswhileworking.

The following target groups are addressed in these instructions:

Version 1.2 (08/2022) en

Translation of original operating instructions 7 of 40

Safety

Operators

Operators have been instructed in operating and cleaning the Pallet Drive and follow the safety guidelines.

Service personnel

The service personnel features a technical training or has undergone training by the manufacturer and performs the

maintenance and repair tasks.

Electricians

Persons working on electrical installations must have pertinent technical training.

2.5 Dangers

The following list informs you about the various types of danger or damage that may occur while working with the

Pallet Drive.

Bodily injury

• MaintenanceorrepairworkonPalletDrivesmustonlybeperformedbyauthorizedservicepersonsinaccordance

with applicable regulations.

• BeforeturningonthePalletDrive,ensurethatnounauthorizedpersonsareneartheconveyor

Electricity

Performanyinstallationandmaintenancetasksonlyafterfollowingthevesafetyrules:

• Disconnect

• Secure against reactivation

• Determinede-energizedstateatallpoles

• Ground and short circuit

• Cover or block neighboring live parts

Rotating parts

• Do not reach into areas between Pallet Drive and conveyor belts or roller chains.

• Tie long hair together.

• Never wear loose clothing.

• Neverwearjewelery,suchasnecklacesorbracelets.

Hot motor parts

• Do not touch the surface of the Pallet Drive. It can result in burns, even under regular operating temperature.

Working environment

• Do not use the Pallet Drive in explosive atmospheres.

• Remove equipment or material which is not required from the workspace.

• Wear safety shoes.

• Clearly specify and monitor the way materials are placed on the conveyor.

8 of 40

Version 1.2 (08/2022) en

Translation of original operating instructions

Safety

Faults during operation

• Regularly check the Pallet Drive for visible damage.

• In case of fumes, unusual noise or blocked or damaged materials, stop the Pallet Drive at once and ensure that the

RollerDrive cannot be started accidentally.

• Contactqualiedpersonnelimmediatelytondthesourceofthefault.

• During operation, do not step on the Pallet Drive or the conveyor/the system in which it is installed.

Maintenance

• Checktheproductregularlyforvisibledamages,unusualnoiseandrmseatingofttings,screwsandnuts.An

additional maintenance is not required.

• Do not open the Pallet Drive.

Accidental motor start

• Take care during installation, maintenance work and cleaning or in the event of a Pallet Drive fault: The Pallet Drive

could start up unintentionally.

2.6 Interfaces to other devices

HazardsmayoccurwhileintegratingthePalletDriveintoacompletesystem.Thesearenotpartofthismanualand

havetobeanalyzedduringthedesign,installationandstartupofthecompletesystem.

• After assembling the Pallet Drive in a conveyor module, check the whole system for a new potential dangerous spot

before switching on the conveyor.

• Additional constructive measures may be required.

Version 1.2 (08/2022) en

Translation of original operating instructions 9 of 40

Product information

3 Product information

3.1 Product description

The Pallet Drive is a completely enclosed electrical drive roller. It replaces external components such as motors and

gears, which require frequent maintenance.

ThePalletDrivecanbeoperatedinenvironmentswithheavycoarseandnedustexposure.

The Pallet Drive is driven by an asynchronous three-phase induction motor. It is available in a single power stage only

and for most of the international supply voltages.

The Pallet Drive does not contain any oil and is not intended for continuous operation.

3.1.1 Options

Integrated thermal overload protection

A thermal circuit breaker integrated in the winding head protects against overheating. The switch trips if the motor

overheats. However, it has to be connected to a suitable external control device that interrupts the current supply to

the motor in case of overheating:

Integrated electromagnetic brake

The integrated electromagnetic brake can hold loads. It acts directly on the rotor shaft of the Pallet Drive and is

drivenbyarectier.TheholdingforceofeachPalletDrivewithbrakecorrespondstothebeltpullofthemotor.The

electromagnetic brake is available for all Pallet Drive:

3.2 Thermal protection

Under normal operating conditions, the thermal circuit breaker integrated in the stator winding is closed. When the

motor limit temperature is reached (overheating), the switch opens at a preset temperature to prevent damage to the

motor.

WARNING

The thermal circuit breaker is automatically reset after the motor has cooled o.

Inadvertent start-up of the motor

¾Connect the thermal circuit breaker in series with a suitable relay or contactor so that the current supply to

the motor is safely interrupted when the switch trips.

¾Ensurethatthemotorcanbeswitchedonagainafteroverheatingonlywithaconrmationbutton.

¾Aftertheswitchhastripped,waituntilthemotorhascooledo,andensurepriortoswitch-onthatthereis

no danger to persons.

10 of 40

Version 1.2 (08/2022) en

Translation of original operating instructions

Product information

Standard design: temperature limiter, automatically switching back

Service life: 10.000 cycles

AC cos φ = 1 2,5 A 250 V AC

cos φ = 0,6 1,6 A 250 V AC

DC 1,6 A 24 V DC

1,25 A 48 V DC

Service life: 2.000 cycles

AC cos φ = 1 6,3 A 250 V AC

Reset temperature 40 K ± 15 K

Resistance <50mΩ

Contact bounce time < 1 ms

3.3 Type plate of Pallet Drive

TheinformationonthenameplateofthePalletDriveisintendedforitsidentication.ThisistheonlywayforthePallet

Drive to be used properly.

A laser-cut nameplate is located on the cover of the Pallet Drive. In addition, the Pallet Drive includes a label that can

be used for documentation.

Version 1.2 (08/2022) en

Translation of original operating instructions 11 of 40

Product information

Nameplate (1) for Pallet Drive DP 0080/DP 0089

Nameplate (2) for Pallet Drive DP 0080/DP 0089

12 of 40

Version 1.2 (08/2022) en

Translation of original operating instructions

Product information

1 Connection diagram number 16 CE mark

2 Rated power 17 UKCAmark

3 Number of poles + operating mode 18 UL mark

4 Rated frequency 19 International Electrotechnical Commission: Standard

for drum motors

5 Rated voltage at rated frequency 20 Type + design

6 Rated current at rated frequency 21 Installation length

9 QR code 22 Weight

10 Power factor 24 Circumferential speed of drum tube

12 Serial number 25 Manufactured week/year/country

15 Manufacturer’s address 27 Technical data of option

3.4 Product identication

TheinformationgivenbelowisrequiredinordertoidentifyaPalletDrive.ThevaluesforaspecicPalletDrivecanbe

entered in the last column.

Information Possible value Own value

Type plate of Pallet Drive Motor type

Speed in m/s

Serial number

Between frames (BF) in mm

Number of poles

Power in kW

Drum diameter (tube diameter) e.g. 80 mm

3.5 Technical data

Protection rate IP54

Ambient temperature range for standard applications -5 °C to +40 °C

Cycle times (duty cycle DC50) 120 pallets per hour

Ramp times PalletDrive:≥0,5s

Installation altitude above sea level max. 1000 m

Version 1.2 (08/2022) en

Translation of original operating instructions 13 of 40

Product information

3.6 Electrical data

Abbreviations see page 33.

3.6.1 DP 0080 3-phase and DP 0089 3-phase

PN nPnNfNUNINcos φηJRIS/INMS/MNMB/MNMP/MNMNRM

W min-1 Hz V A kgcm2Nm Ω

0,07 2 2889 50 400 0,33 0,56 0,54 1,25 4,2 4 4,5 4 0,23 72,7

0,07 2 2889 50 230 0,57 0,56 0,54 1,25 4,2 4 4,5 4 0,23 72,7

3.7 Dimensions

All length-related dimensions in the catalog and in these operating instructions comply with the requirements of DIN/

ISO 2768 (medium quality).

The recommended distance between the mounting brackets (EL) while taking into account the maximum

thermal expansion and internal tolerances is EL + 2 mm.

14 of 40

Version 1.2 (08/2022) en

Translation of original operating instructions

Product information

Dimensions of Pallet Drive

Type A

mm

EL

mm

AGL

mm

DP 0080 80 RL+V+13 RL+V+28

DP 0089 89 RL+V+13 RL+V+28

Version 1.2 (08/2022) en

Translation of original operating instructions 15 of 40

Options and accessories

4 Options and accessories

4.1 Electromagnetic brake for the Pallet Drive

The electromagnetic brake, which is available as an option, acts directly on the rotor shaft. If the power supply is

interrupted, the brake is applied and holds the Pallet Drive in position until the power supply is re-established. The load

heldbythebrakecorrespondstothemaximumtransportweightspeciedforthePalletDrive.

Features:

• Applied directly to the rotor shaft of the Pallet Drive.

• Holdsaloadequaltothespeciedtransportweight.

• Operationviaanexternalrectier.

• Operating temperature from -10 °C to +120 °C.

TheratedbrakingtorqueisheavilyinuencedbytheoperatingconditionsinsideofthePalletDriveaswell

astheambienttemperature.Forsafetyreasons,thespeciedbrakingtorqueshouldbereducedby50%for

load calculations.

Brake type Rated braking

torque

Rated output Rated supply voltage Rated current

Nm W V DC mA

24 2 11 24 500

The installed brake disk is a wear part and has a limited service life in relation to the operating conditions. In case

of premature wear, the operating conditions must be checked and evaluated. The wear parts of the brake are not

included in the product warranty.

The braking torque at the Pallet Drive tube corresponds to the gear ratio of the motor times the braking

torquelistedinthetableabove.Forsafetypurposes,25%reservehavetobeguredintothedimensioning

of the brake. The brake is not a safety holding brake.

All brakes are dimensioned for start/stop operation.

Theriseandfalldelaysofthebrakescanvarysignicantlydependingonthefollowingfactors:

• Ambient temperature

• Internal operating temperature of Pallet Drive

16 of 40

Version 1.2 (08/2022) en

Translation of original operating instructions

Options and accessories

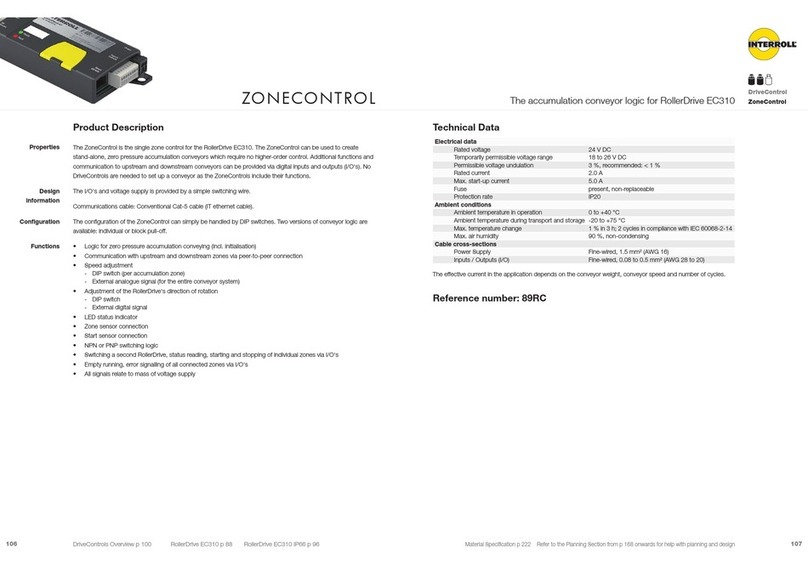

4.2 Asynchronous Pallet Drive with frequency inverters

4.2.1 Torque dependent on input frequency

Operatingfrequency[Hz] 5 10 15 20 25 30-50

Availablemotortorquein%of

ratedmotorfrequency50Hz

80 85 90 95 100 100

ThetorquedependencydepictedinthegureaboveisexpressedasP=Txω. With a reduced operating frequency

ofbelow20/24Hz,themotortorqueisreducedbychangingheatdissipationconditions.

4.2.2 Frequency inverter parameters

Clock frequency:

Ahighclockfrequencyleadstoabetterutilizationfactorofthemotor.Optimumfrequenciesare8or16kHz.

Parameterssuchassmoothrunningtestquality(motorisrunningsmoothly)andnoisedevelopmentarealsoaected

positively by high frequencies.

Voltage increase:

Interrollmotorwindingsaredesignedforaratedvoltageincreaserateof1kV/μs.Ifafrequencyinvertergenerates

a steeper voltage increase, motor chokes must be installed between the frequency inverter and the motor. However,

since all Interroll Pallet Drives run in an oil bath, the risk of overheating or damage to the motor due to high voltage

increase rates is extremely low. Contact your local Interroll dealer about the need for motor chokes.

Voltage:

Ifafrequencyinverterwithsingle-phasesupplyisinstalledinthePalletDrive,thespeciedmotormustbedesignedfor

the frequency inverter output voltage and must be connected accordingly. Single-phase motors cannot be operated

with a frequency inverter.

Version 1.2 (08/2022) en

Translation of original operating instructions 17 of 40

Options and accessories

Frequency inverter parameters:

Frequency inverters are usually delivered with factory settings. Given these settings, the inverter is generally not

immediatelyreadyforoperation.Theparametershavetobeadjustedtotherespectivemotor.Forfrequencyinverters

soldbyInterroll,startupinstructionsspecicallycreatedforPalletDrivefortherespectivefrequencyinverterscanbe

supplied upon request.

Maximum frequency:

ThePalletDrivemaybeoperatedonlyinafrequencyrangefrom10-50Hz.

18 of 40

Version 1.2 (08/2022) en

Translation of original operating instructions

Transport and storage

5 Transport and storage

5.1 Transport

CAUTION

Improper transport poses a risk of injury!

¾Transport-relatedtasksshouldonlybecarriedoutbyqualiedandauthorizedpersons.

¾For Pallet Drives with a weight of 20 kg or more, use a crane or hoisting equipment during the transport.

The rated load of the crane or hoisting equipment must be greater than the weight of the Pallet Drive. Crane

rope/cable and hoisting equipment must be securely fastened to the shafts of the Pallet Drive during lifting.

¾Do not stack pallets.

¾Beforethetransport,ensurethatthePalletDriveissucientlysecured.

NOTICE

Risk of damage to the Pallet Drive due to improper transport!

¾Avoid strong impacts during transport.

¾Do not lift the Pallet Drive at the cable or at the terminal box.

¾Do not transfer the Pallet Drives between warm and cold environments. This may cause condensation to

form.

¾For transport in shipping containers, ensure that the temperature in the container is not permanently above

70 °C (158 °F).

1. Check each Pallet Drive for damage after transport.

2. In the event of damage, take photos of the damaged parts.

3. In case of a transport damage, immediately notify the carrier and Interroll to avoid losing any claims for

compensation.

5.2 Storage

CAUTION

Risk of injury due to improper storage!

¾Do not stack pallets.

¾Do not stack more than four cardboard boxes on top of each other.

¾Ensure that proper fastening is in place.

1. Store the Pallet Drive in a clean, dry and enclosed location at +15 to +30 °C; protect it from moisture and

humidity.

2. Check each Pallet Drive for damage after storage.

Version 1.2 (08/2022) en

Translation of original operating instructions 19 of 40

Assembly and installation

6 Assembly and installation

6.1 Warning notices concerning the installation

CAUTION

otating parts and inadvertent startup of the motor!

Riskofcrushingforngers.

¾Do not reach into areas between Pallet Drive and conveyor belts or roller chains.

¾Installaprotectiondevice(suchasaguardplate)topreventngersfromgettingtrappedinthechainbelts

or roller chains.

¾Install an appropriate warning on the conveyor.

NOTICE

Risk of damage leading to failure or shortened service life of the Pallet Drive!

¾Do not drop or mishandle the Pallet Drive to avoid internal damages.

¾Prior to the installation, inspect each Pallet Drive for damage after storage.

¾Do not hold, carry, or support the Pallet Drive by the wires or terminal boxes extending out of the mounting

shaft to avoid damage to the internal parts and seals.

¾Do not twist the motor cable.

6.2 Installing the Pallet Drive

6.2.1 Positioning the Pallet Drive

Ensurethatthedataonthetypeplatearecorrect,andmatchtheorderedandconrmedproduct.

TheinstallationofaPalletDriveispermissibleonlyinhorizontalapplications.Incaseofdoubt,contact

Interroll.

ThePalletDrivemustbemountedhorizontallywithaclearanceof+/-2°.

The Pallet Drive can be installed in any orientation.

20 of 40

Version 1.2 (08/2022) en

Translation of original operating instructions

Assembly and installation

6.2.2 Installation of Pallet Drive in mounting brackets

Themountingbracketsmustbesucientlyrobusttowithstandthemotortorque.

1. Install the brackets at the conveyor or machine frame. Ensure that the Pallet Drive is installed parallel to the

transport rollers and at a right angle to the conveyor belt frame.

2. Ensurethatatleast80%ofthekeysurfacesofthePalletDriveareheldbythemountingbrackets(cableside).

3. Ensure that the distance between the key surfaces and the bracket is free from play.

4. On the side without cable, use a screw M12; 8.8 and tighten with a tightening torque of 80 Nm.

The Pallet Drive can also be installed without mounting brackets. In this case, the shaft end of the cable side

must be installed in a corresponding recess in the conveyor belt frame; this recess must be designed in such

a way that the aforementioned requirements are met.

Axial play

1 Torque tension displacement

The entire axial clearance of the Pallet Drive should measure 1 mm minimum and 2 mm maximum.

This manual suits for next models

1

Table of contents

Other Interroll DC Drive manuals

Popular DC Drive manuals by other brands

Pfeiffer Vacuum

Pfeiffer Vacuum TC 1200 PB Translation of the original

Siemens

Siemens 6SL3845-7NN46-7AA2 Operating instructions & installation instructions

ABB

ABB ACL30 user manual

Bosch

Bosch Rexroth EFC 3600 Easy start guide

Danfoss

Danfoss VLT 2800 manual

Rockwell Automation

Rockwell Automation Allen-Bradley PowerFlex 7000 Series user manual