Interroll RollerDrive EC310 User manual

Other manuals for RollerDrive EC310

2

This manual suits for next models

4

Table of contents

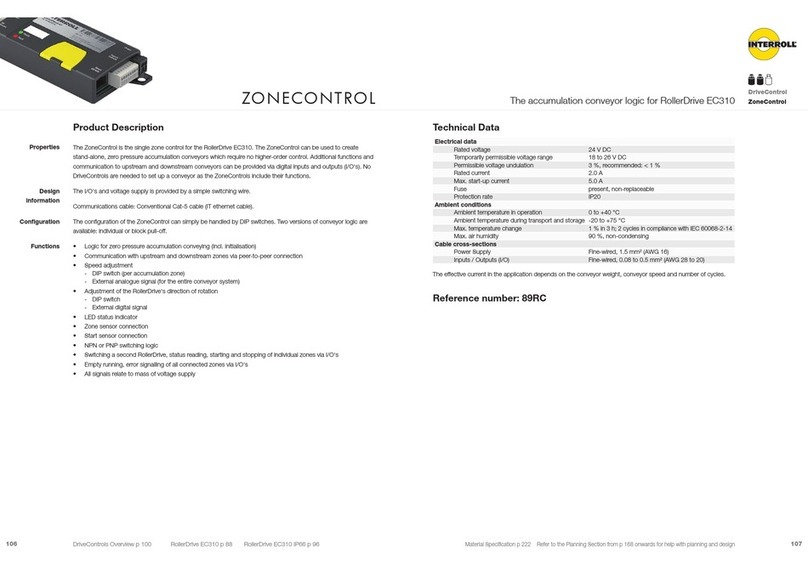

Other Interroll DC Drive manuals

Popular DC Drive manuals by other brands

SOMFY

SOMFY Sonesse 28 WireFree RTS Li-ion instructions

Chauvet Professional

Chauvet Professional onAir Flex Drive 2 Quick reference guide

Wittenstein cyber motor

Wittenstein cyber motor simco SIM2002D operating manual

Siemens

Siemens SINAMICS G110 operating instructions

Leadshine

Leadshine MX3660 Hardware installation manual

Carotron

Carotron Elite Pro V3 instruction manual

ABB

ABB DCS800 Firmware manual

Leeson

Leeson SPEEDMASTER SM2 Series Installation and operation manual

SEW-Eurodrive

SEW-Eurodrive MOVIMOT MMxD Series Compact operating instructions

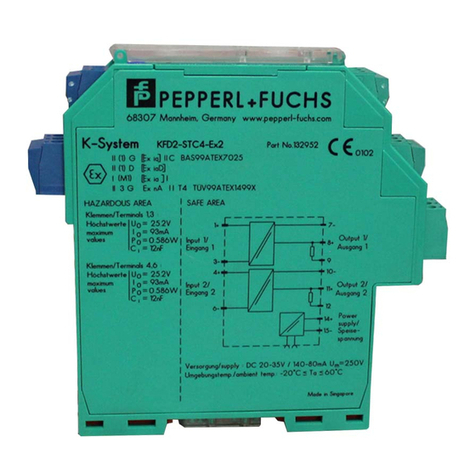

Pepperl+Fuchs

Pepperl+Fuchs KFD2-SCD2-Ex LK Series manual

VLT

VLT AQUA Drive FC 200 instruction manual

Leadshine

Leadshine DM2282T user manual

SOMFY

SOMFY Sonesse Ultra 50 RS485 instructions

Dorner

Dorner 62M050PLBDDEN Installation, Maintenance, and Parts Manual

Superior

Superior SLO-SYN SS2000MD4 installation instructions

Power Electronics

Power Electronics SD700 Series Hardware and installation manual

Concept2

Concept2 2SC0435T Description and Application Manual

Trane

Trane TR150 Programming guide