* (according to EN 60529); ** (according to IEC 1140)

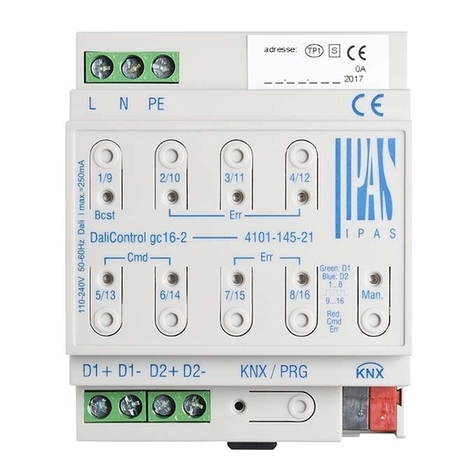

Location and function of the LEDs and control elements

1: KNX bus connector

2: Programming button

3: Programming LED

4: SD card slot (only for internal use)

5: Outputs connector: Channel A, B, C, D

6.1: Manual control (See Annex 1)

Blind channel:

- Long press: Move Up (LED blinks while moving)

- Short press: Stop/Step

Binary channel:

- Short press: Output toggles to ON/OFF

6.2: Manual control (See Annex 1)

Blind channel:

- Long press: Move Down (LED blinks while moving)

- Short press: Stop/Step

Binary channel:

- Short press: Output toggles to ON/OFF

7.1: LED output/channel status

Binary channel LED ON = Output ON, LED OFF = Output OFF /

Shutter: LED blinks while moving UP

7.2: LED output/channel status

Binary channel LED ON = Output ON, LED OFF = Output OFF /

Shutter: LED blinks while moving DOWN

8: Outputs connector: Channel E, F, G, H

Mounting and wiring

As an REG device, the Power Block series are suitable for mounting in

distribution boxes on 35 mm DIN rails and wall boxes.

To mount the device, it must be angled to slide onto the DIN rail from

above and then locked into place with a downward movement.

Please make sure that the security latch at the bottom side of the

device snaps into place and that the device is firmly attached to the

rail. To dismount the device, the security latch can be pulled

downwards with a suitable tool and then the device can be removed

from the rail.

After the device has been inserted, the cables for the Outputs should

be attached to the upper and lower connectors. However, please make

sure that these are labelled clearly.

To connect the KNX cable, a standard bus connector is plugged into

the respective entry on the device. Please make sure that there is

double basic insulation between the KNX installation and the power

supply. To do so, please insulate the wires of the KNX cable up to the

bus connector with the enclosed shrinkable tubing.

Please make sure that the cables are laid in a way that ensures

sufficient distance between the inputs and outputs cables.