13. INSTALLATION COMPLETE

Cabinet is now fully installed!

9. ADD TRIM

Add decorative trim or molding to

make cabinet sides ush with the face

frame.

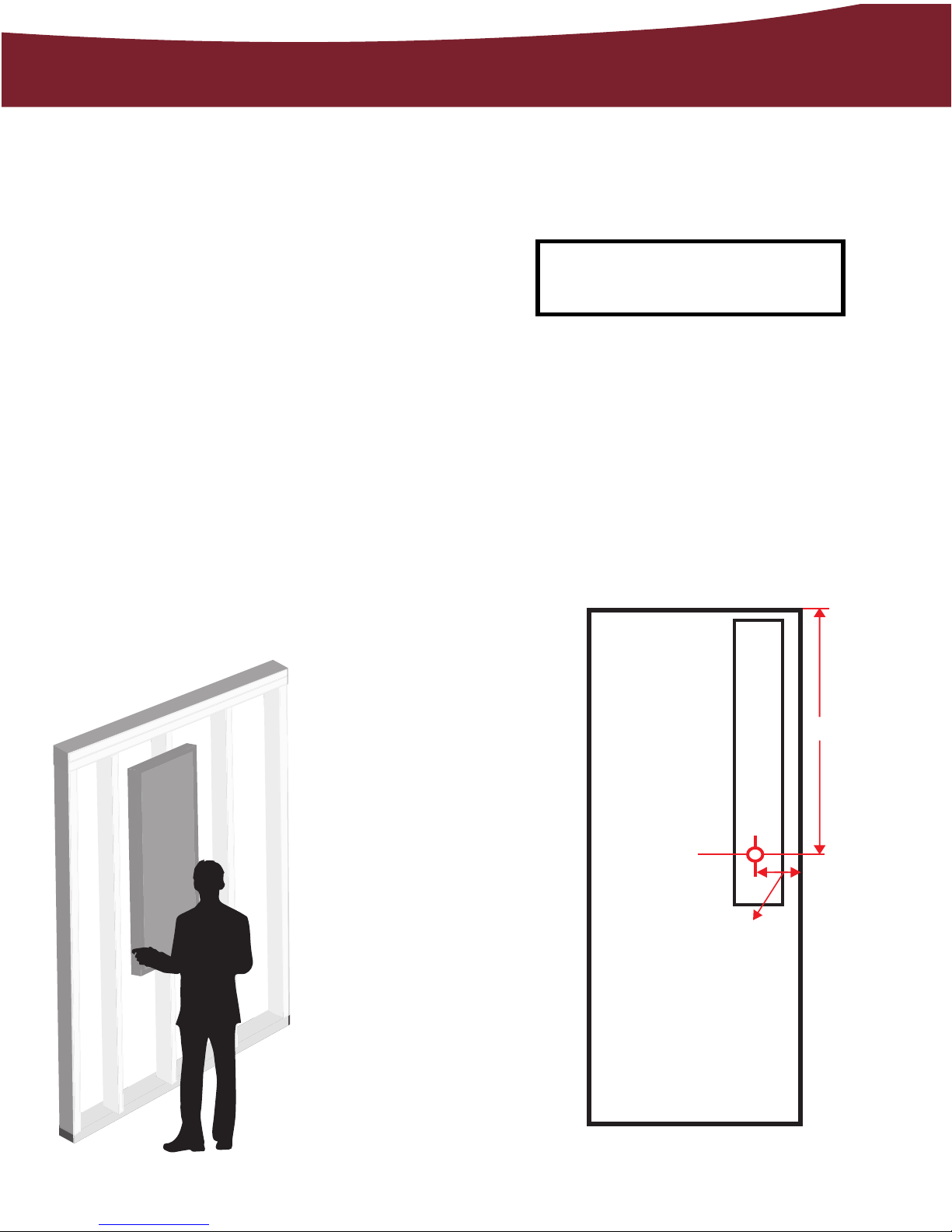

Locate side ironing board brackets

that are secured to cabinet with

three screws. Then remove the top

screw from each bracket. Replace

with a #14 x 3/4” Phillips screw. This

will add stability long-term.

10. REMOVE BRACKET SCREW

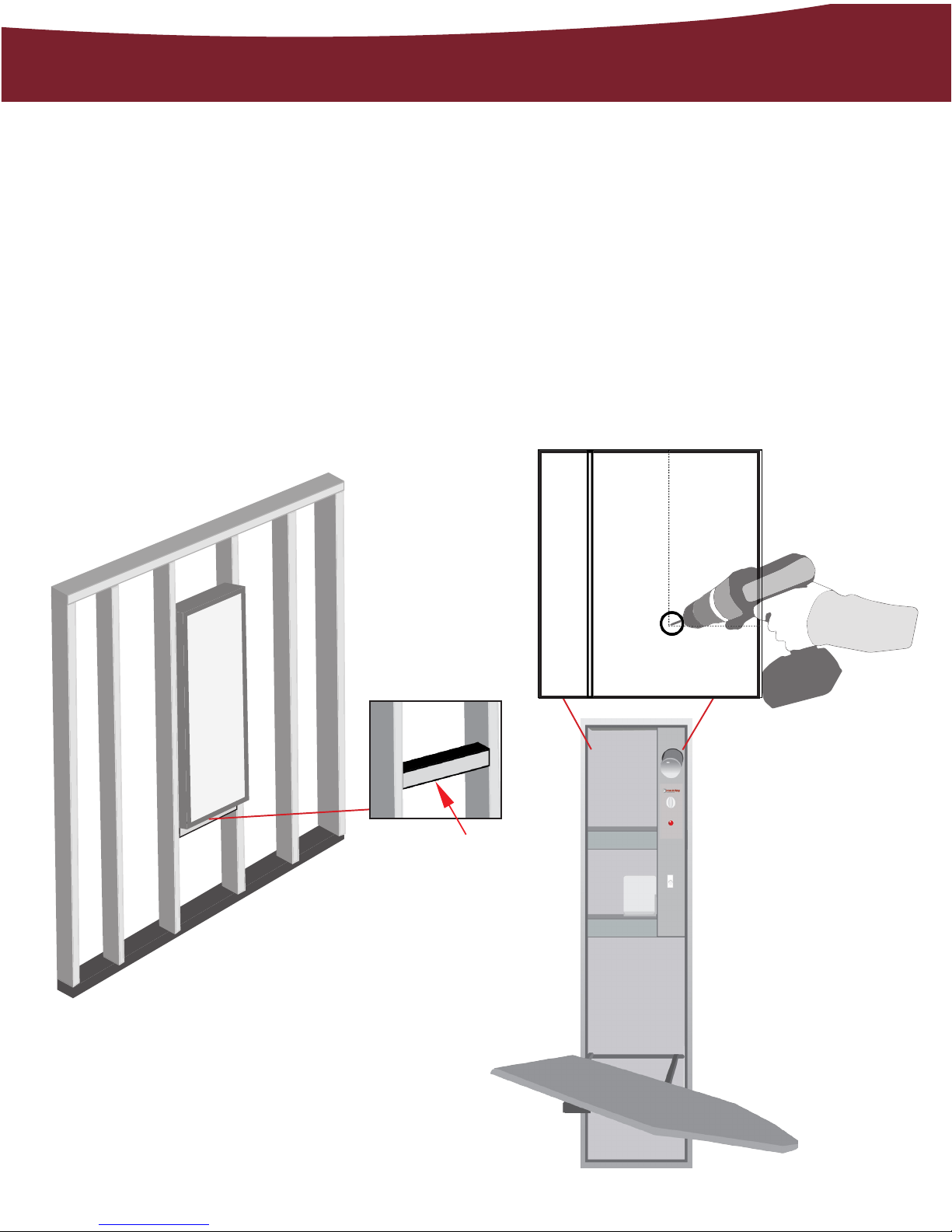

7. INSTALL UNIT

Begin installation by carefully lifting

unit into position. Then, attach the

cabinet to the wall by fully inserting

the screw in the upper cross brace

into the wall stud.

Make sure the unit is plumb and

level. Shim if necessary. Fully tighten

installation screw.

8. INSERT SECOND SCREW

Insert the second #14 x 4” screw into

the pre-drilled hole in the bottom

brace of the cabinet and attach to

wall making sure cabinet remains

square and level.

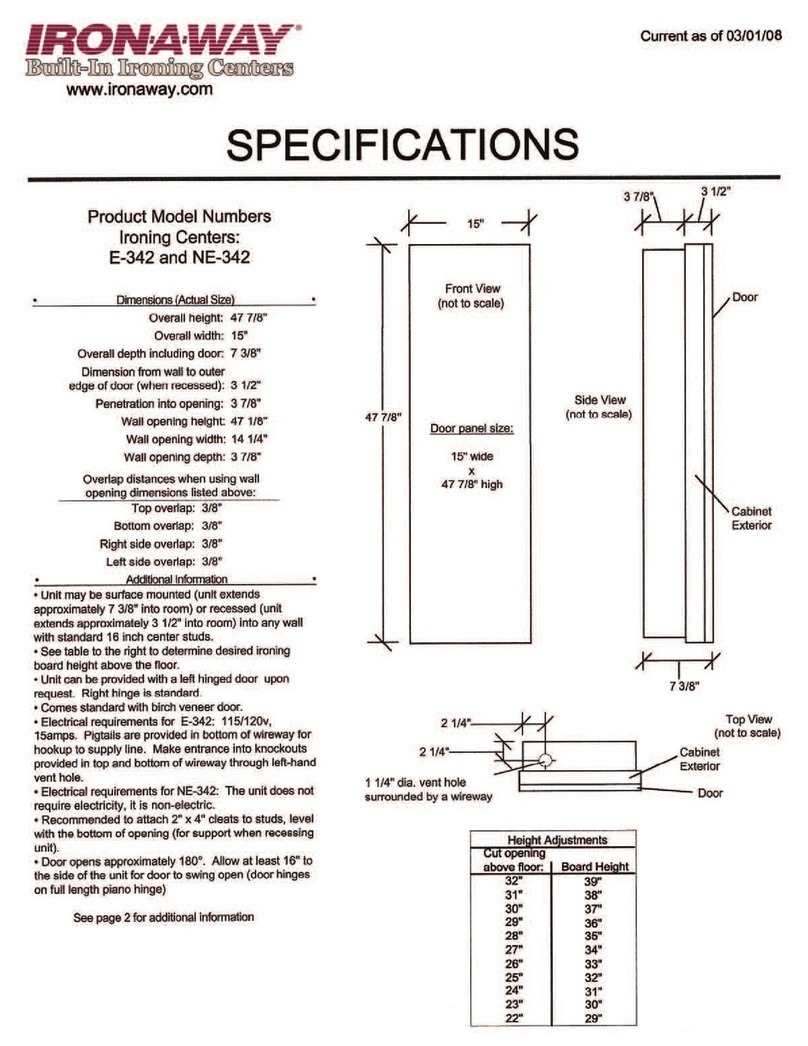

6. INSTALL ELECTRICAL WIRING

Verify that there is ample supply wire

available to run from the top of the

ironing center to the approximate

location of electrical pigtails.

Note: A free wire length of 48” is

recommended.

Begin to place the ironing center into

its location while feeding the supply

wire through electrical knockout,

and the 3/8” romex connector

through the back of the raceway.

11. CONNECT WIRES

Connect all power supply wires and

ground wires in accordance with all

electrical codes. Trim supply wire as

necessary.

12. REPLACE RACEWAY COVER

Place the raceway cover into

position, ensuring that no wires

are pinched. Reinstall the top and

bottom screw to secure in place.

Reconnect power supply.