PM605KT/PM605KT-BTechnicaldocumentation

8

Stop operation when abnormal sound is heard during operation.

Failuretofollowthiscouldresultinunexpectedaccidents.

Do not use in a way exceeding the range of the product

specifications.

Failuretofollowthiscouldresultinmalfunction,fire,and/orinjury.

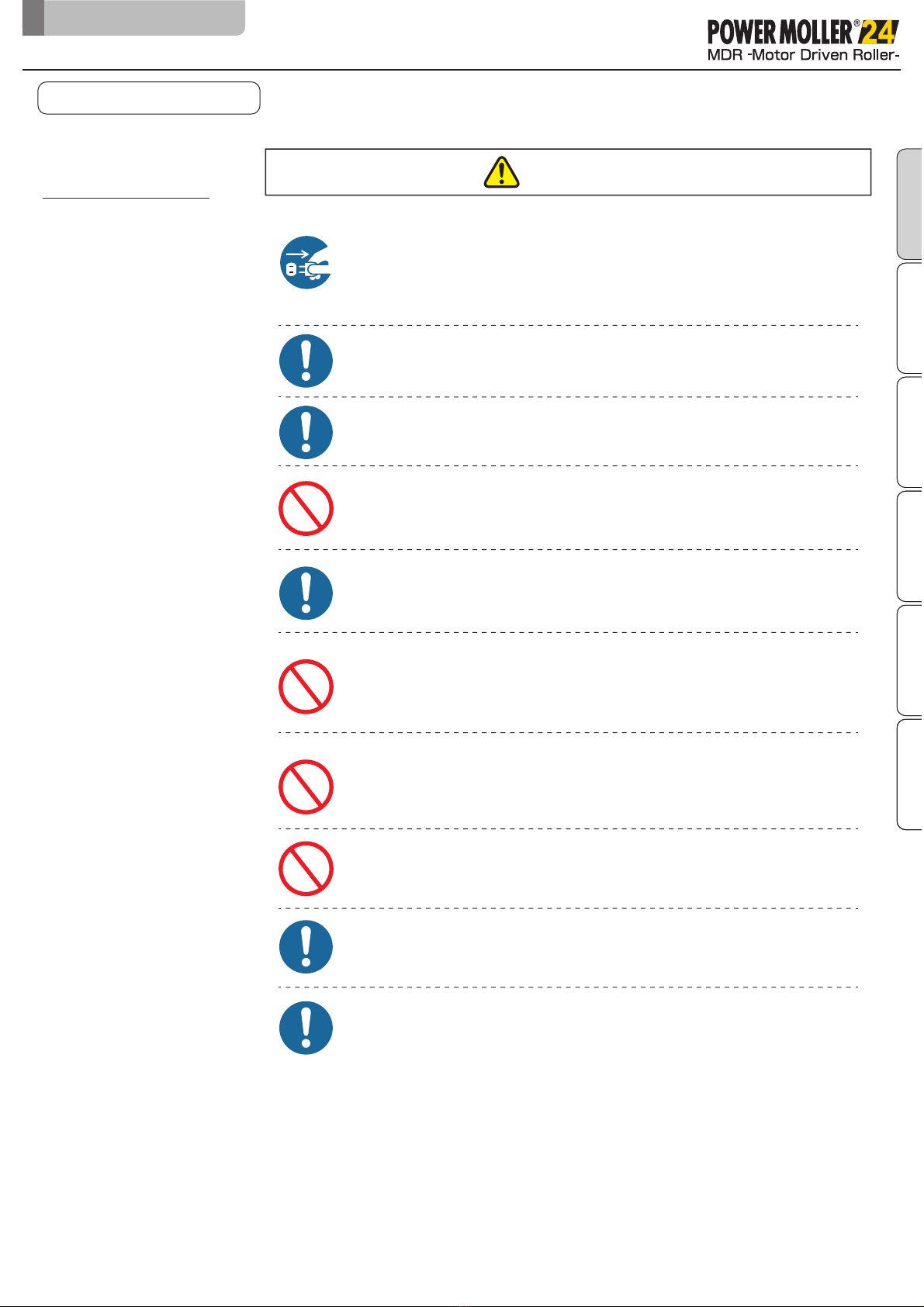

WARNING

CAUTION

Do not use the product near places subject to explosive,

flammable gas, and/or corrosive atmosphere, and/or

combustible materials.

Failure to follow this could result in explosion, fire, electric shock and/or

injury.

When using the product in places where serious accidents

and/or damage may possibly occur, install backup and/or

fail-safe functions systematically.

Failure to follow this could result in the inability to control this product due

to driver card malfunction, which could lead to serious accidents.

Do not forcibly bend and/or pull cables.

Also, do not put heavy materials on cables, or do not get them

stuck between cables.

Failure to follow this could result in fire and/or electric shock due to cable

damage.

Make sure to attach ground wires to the conveyor body and DC

power supply unit.

Failure to follow this could result in electric shock if any malfunction or leakage

occurs.

Never modify the product and/or driver cards.

Failure to follow this could result in serious accidents.

Do not touch the product when it is running or after it has just

stopped operation.

Failure to follow this could result in burns.

Do not put water and/or oil on the product, and do not transfer

wet and/or oily trays.

Failure to follow this could result in electric shock, and/or malfunction.

3-1.

General precautions

Do not apply strong impact and/or excessive force to the

product, such as hitting it with objects, or dropping it. Also, do

not use the equipment if strong impact has been applied, and/or

if the appearance has become deformed.

Failure to follow this could result in malfunction due to applied impact.

General precautions

3.Safety precautions

Safety precautions

Preparation Before Installation

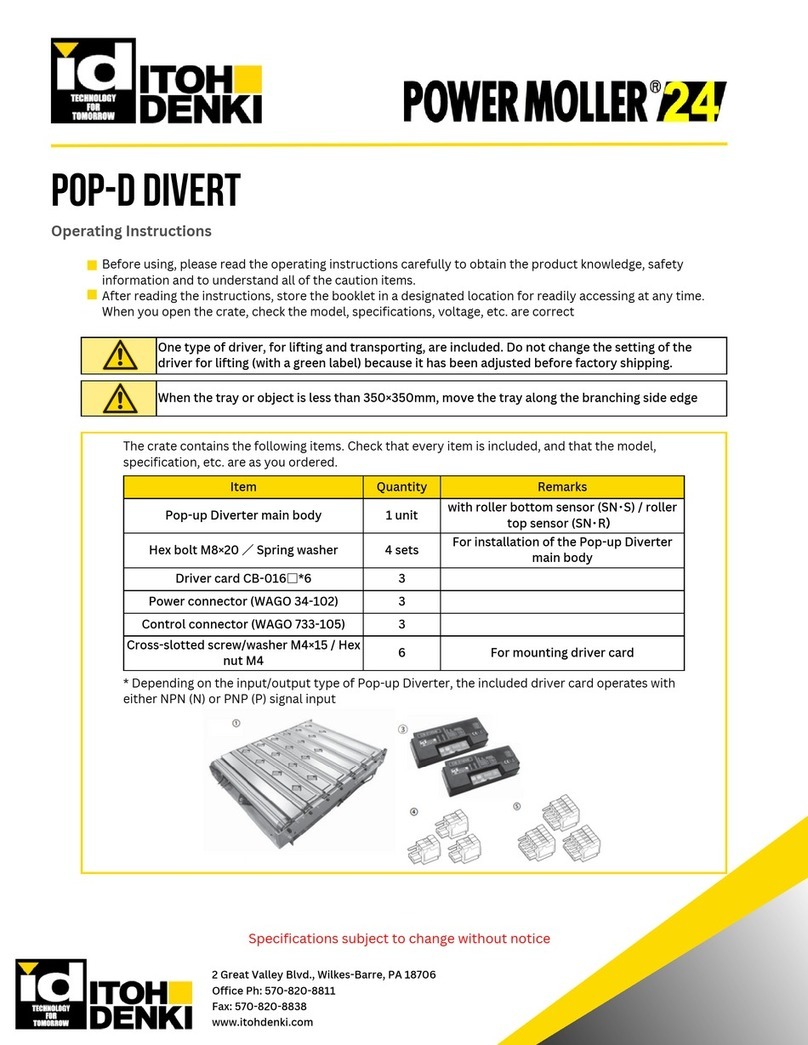

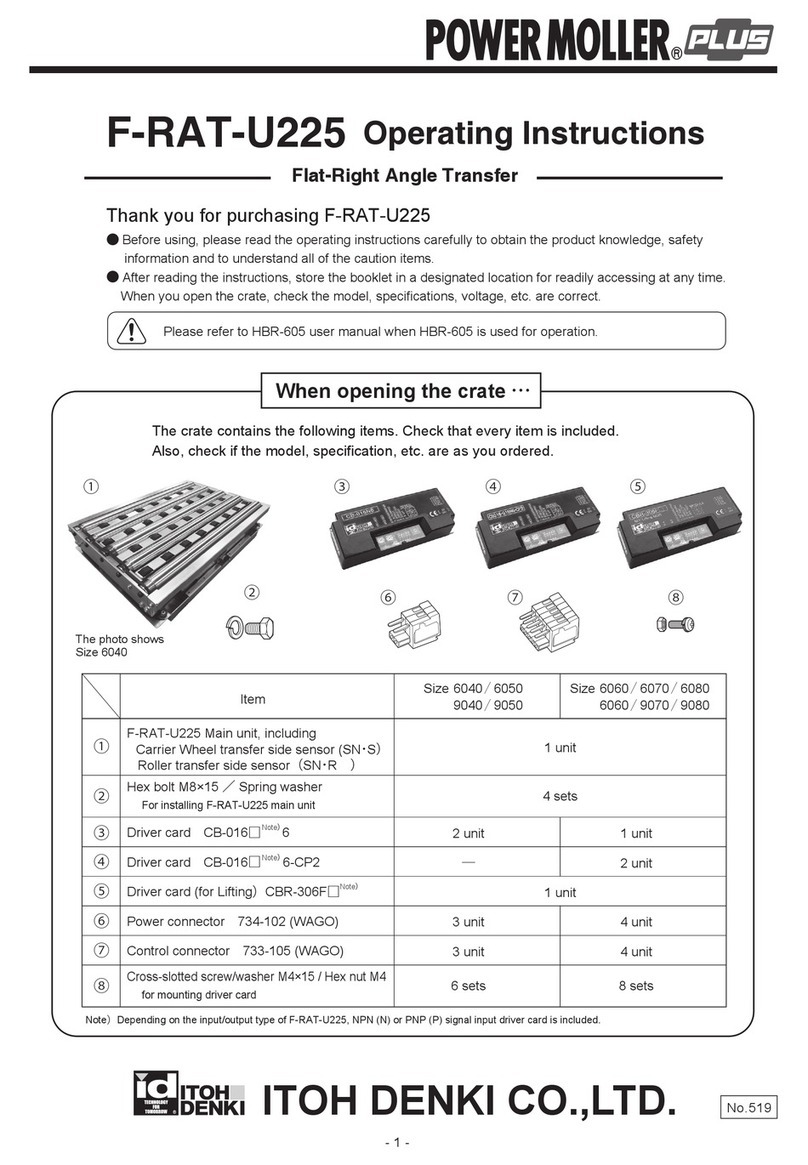

Check productInstallation

Maintenance

Appendix

Original notice - A1.1