25201242 Rev. E

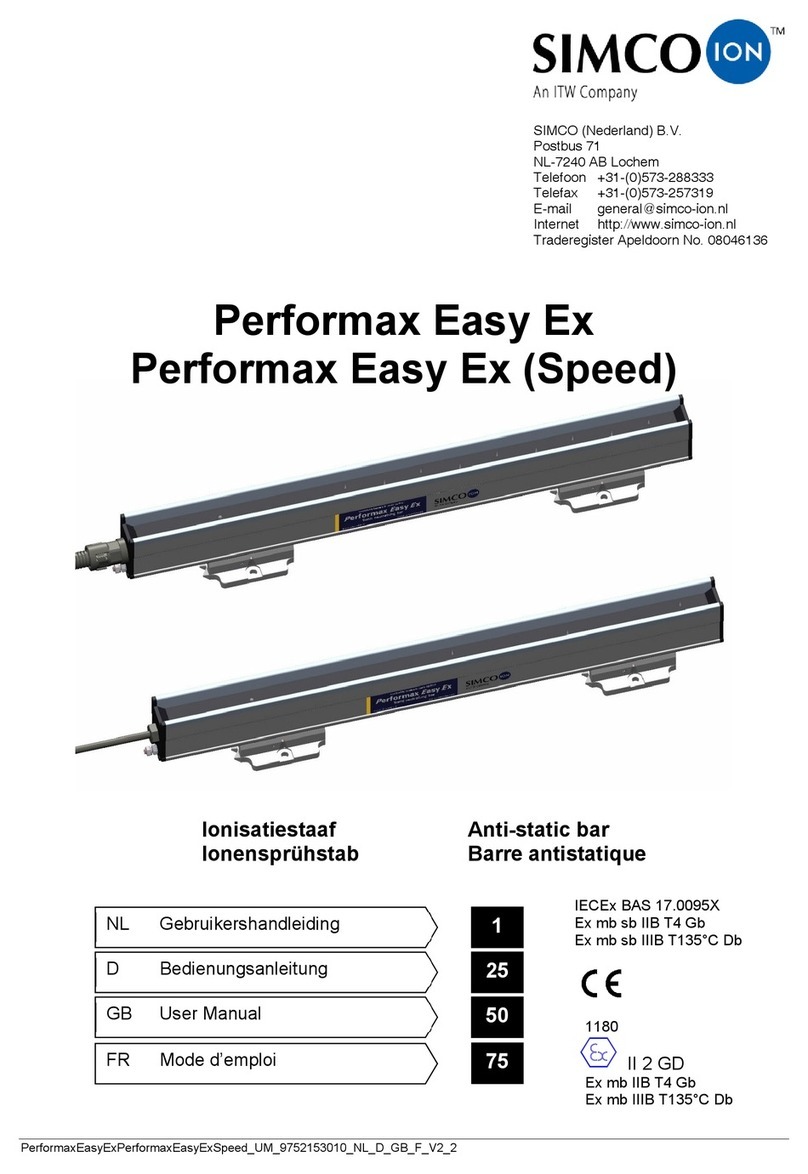

IQ Power Nozzle

2. DESCRIPTION

Electrostatic charges occurring during production processes often result in dust and

debris being attracted to work in process, resulting in defects or contamination. The

IQ Power Nozzle, used in conjunction with an IQ Power supply, provides static

neutralization and cleaning ability. By neutralizing static charges, dust and debris are

released from surfaces. When used in conjunction with compressed air the IQ Power

Nozzle has an excellent range and blow off force. In addition to contamination

control, the IQ Power Nozzle is excellent for sheet separation, even at high speed.

The nozzle can also aid in sheet stacking operations, making it a simple and accurate

process.

The static neutralizing nozzle features current limiting at each individual ion

emitting pin to minimize the risk of hazardous electrical shock if the nozzle is

touched while in operation. This safety feature does not compromise the IQ

Power Nozzle’s ability to neutralize static charges. The emitter pins are made of a

special alloy to extend the longevity and sharpness of the points, providing optimal

performance of the static bar.

The IQ Power Nozzle is intended for use with the IQ Power BPS or LPS. These high

voltage power supply module provide microprocessor controlled high voltage DC

output to the nozzles. This allows direct conditional monitoring of the IQ Power

Nozzle condition and numerous communication and connectivity options.

Features

• Four nozzles can be installed on a single cable

• Flexible mounting options with a position locking bracket

• Nozzle condition can be monitored with IQ Power BPS or LPS

• Quick discharge times, fast static neutralization

• Slotted air outlet for high blow off force

• High-efficiency perforated air outlet for low air consumption & wide area coverage

• IP-66 rated

3. SPECIFICATIONS

Operating Voltage ±7 kVDC, max

High Voltage Connector IQ Power Speed

Operating Temperature 140°F (60°C), max

Humidity No dewing permissible

Air Connection 1/8”NPT push-to-connect fitting for use with 1/4”OD tubing

Air Pressure 80 psi, max (CDA is recommend for longevity)

Air Consumption Slotted: 10 scfm @ 30 psi; Perforated: 1.2 scfm @ 30 psi

Enclosure Glass filled nylon