−3−

●Spraying

*Filter color material with fine filter paper (cloth),or pigments may clog nozzle.

*When spraying lacquer or varnish, add retarder to prevent whitening.

*Never damage nozzle cap or nozzle. If done, it will adversely affect atomization.

*Do not mix different color material (example: paint and dyestuff).

If done, the viscosity will increase and cause malfunction.

(1) Before spraying, loosen needle chucking nut and gradually push needle inwards till needle touches nozzle,

and then retighten needle chucking nut. Pour cleaning liquid into cup and clean fluid passage.

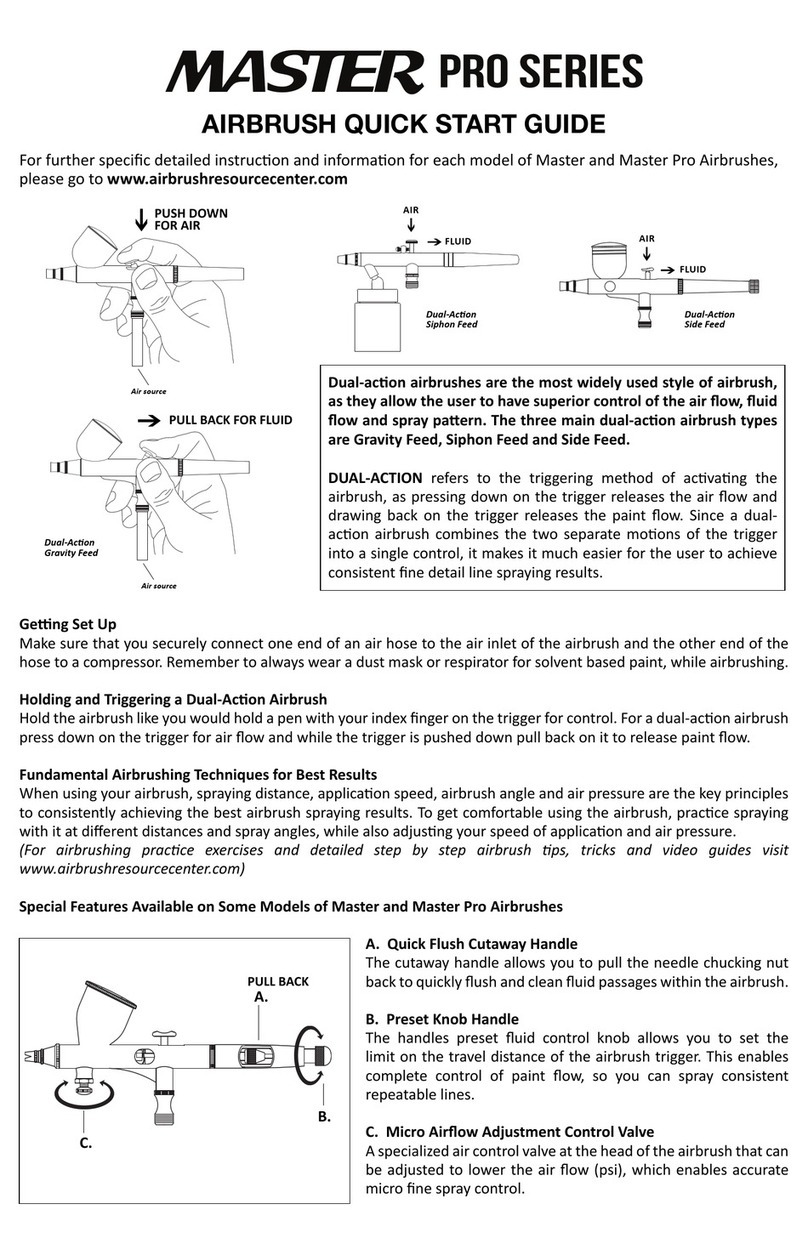

(2) First push main lever with forefinger or thumb downwards in order to release air, and pull it toward you.

Then,color material will come out. Be sure to push main lever forward (originalposition) and detach finger

to stop spraying. If you do not push main lever (without air release), and just pull it forward, a large amount

of color material may jet out.

■Maintenance after Painting

●Maintenance

あWARNING

*Always completely release pressure before maintenance in accordance with warning of safe operation

on page 2. If not done, remaining pressure can cause injuryby the splashing of

cleaning liquid or other misuse.

*The operator must be fully conversant with the requirements in this manual and have sufficient

knowledge and experience.

*Pay full attention to the sharp tip of needle in order to avoid injury.

Maintenance procedure Important

1. Incomplete cleaning can cause adverse pattern shape

and particles.

*Be careful with handling of the tip of needle and nozzle

since they are very weak.

1. After operation, be sure to empty fluid cup and

spray water or cleaning liquid for cleaning.

*Then close tip of nozzle cap with finger and

pour water or solvent into cup. Then if you

push main lever, air flows backward into nozzle

which works like gargling.

2. Pull out needle and remove foreign matter.

Clean needle and insert it till it touches nozzle.

Clean other parts with attached brush soaked

with cleaning liquid and waste cloth.

2. Never immerse the whole airbrush into liquid such as

thinner.

*Immersion for a long time can damage O ring or

packing.

*Never damage holes of nozzle cap,nozzle, or needle.

If done, it can influence atomization adversely.

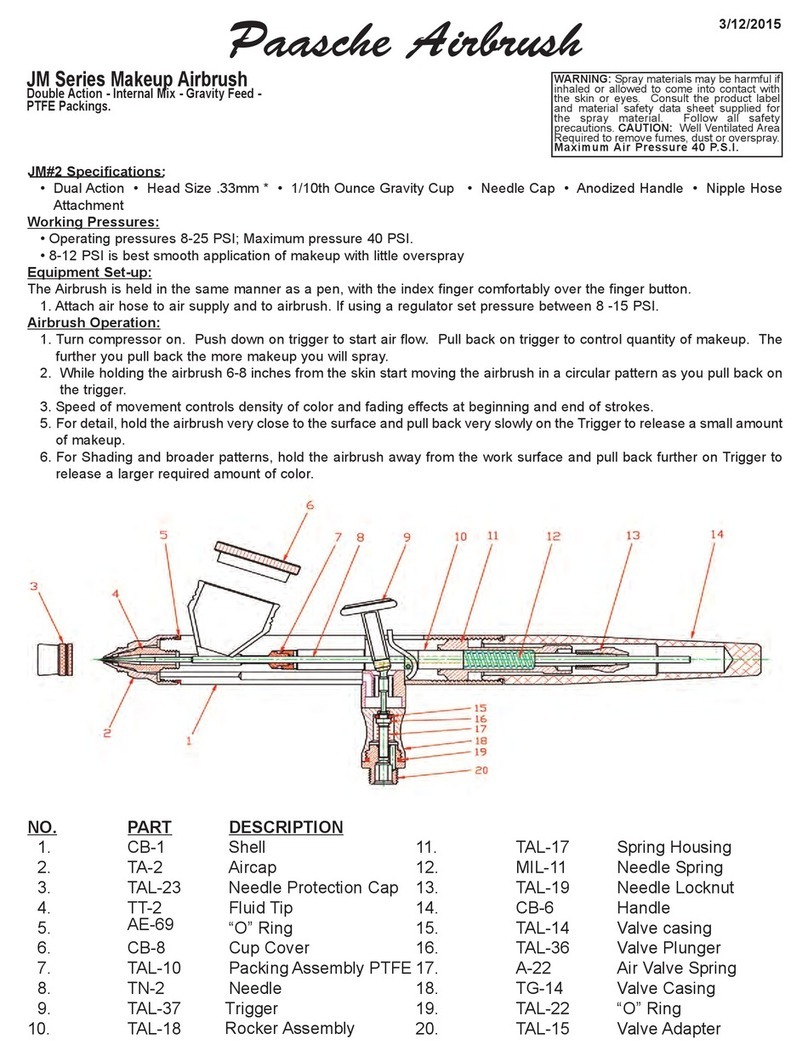

3. Fully clean fluid passage before disassembly. 3. Remove fluid nozzle while pulling needle with main lever

pulled (toward you), in order to protect seat section.

●Inspection

Where to inspect When to replace parts

1. Each hole passage of cap and nozzle *Replace if damaged or deformed.

2. Packing or o rings *Replace if damaged or worn out.

3. Seat section between nozzle and

needle for leakage *Replace if there is still leakage even afteryou clean nozzle and

needle.

If you replace nozzle or needle

only, first match up nozzle and needle to see if there is any leakage.

*When replacing nozzle, use exclusive tool and gradually tighten. Use

of other tools can cause breakage of thread or incomplete centering.

4. Tip of needle *Replace if bent or broken.

You cannot repair abent needle. Replace it with anew one

immediately. Damaged needle can cause adverse atomization and

damage to tip of nozzle or inner diameter.