INSTRUCTIONS AND PARTS LIST TG-TALON 9/25/2020

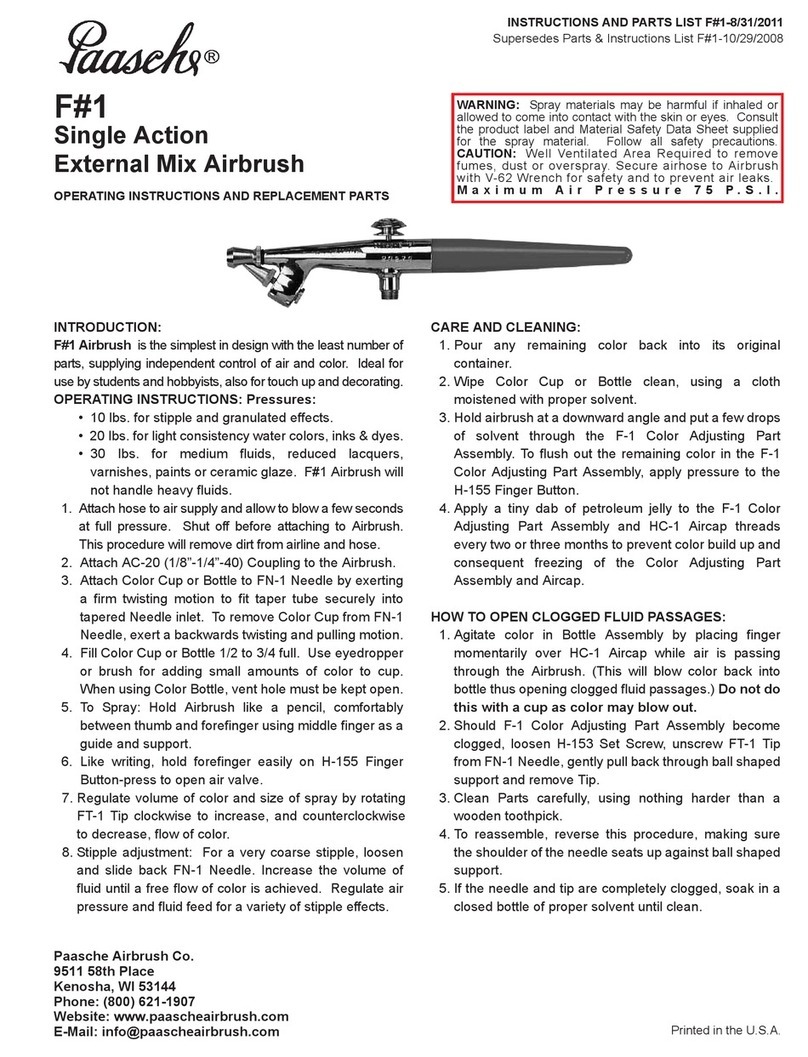

WARNING: Spray materials may be harmful if

inhaled or allowed to come into contact with the

skin or eyes. Consult the product label and material

safety data sheet supplied for the spray material.

Follow all safety precautions. CAUTION: Well

Ventilated Area Required to remove fumes, dust or

overspray. Maximum Air Pressure 75 P.S.I.

Options for Talon:

Operating pressures 15-55 PSI; Maximum pressure 85 PSI. Fan aircap needs 20 PSI or more.

20-30 PSI is best for detail spraying w/ properly thinned paint

Use the higher pressures for thicker material where fine detail is not critical

or thin the paint for lower pressures.

1. Attach air hose to air supply and to airbrush. If using a regulator set pressure between 20-55 psi .

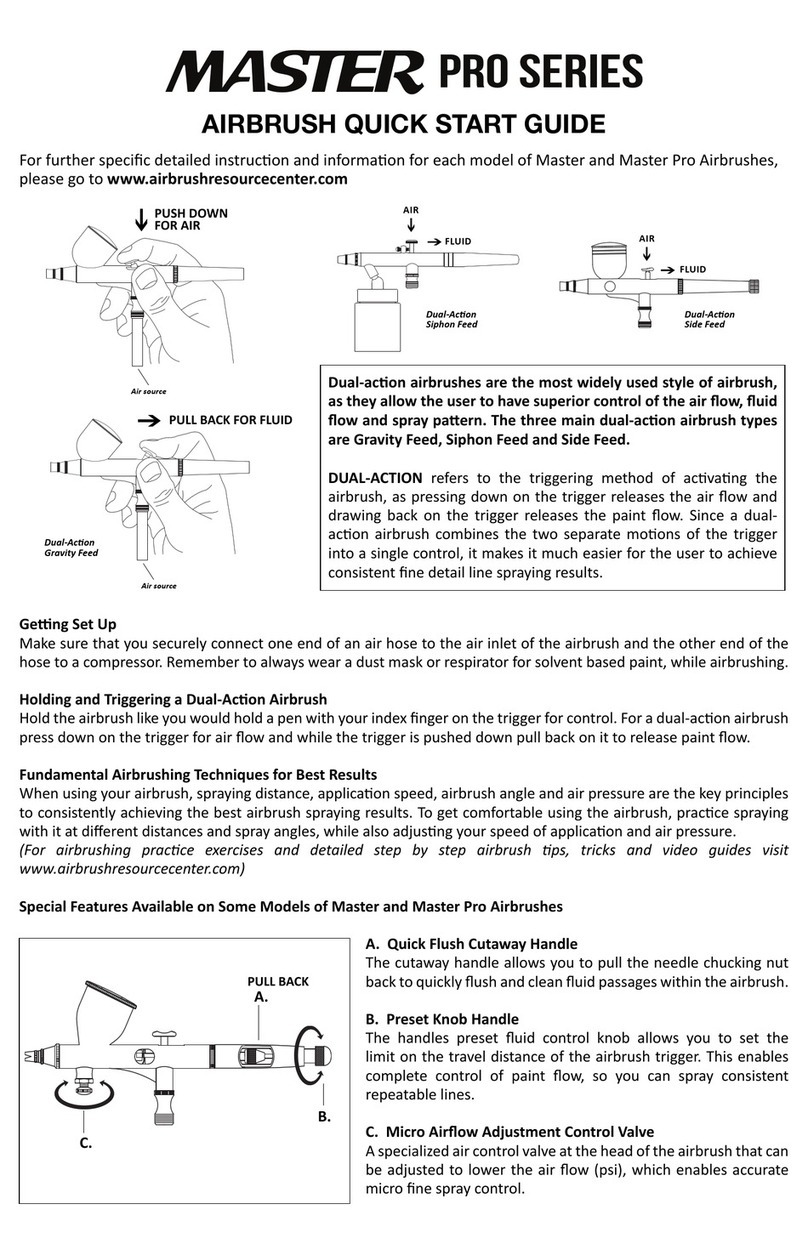

2. Press down on Finger Button to release air and pull back on button to control quantity of color.

3. Speed of movement controls density of color and fading effects at beginning and end of strokes.

4. Practice this movement until you can spray a fine line or a broad pattern without heavy build up at the

beginning or end of your strokes.

5. For detail, hold the airbrush very close to the surface push down for air and pull back very slowly on

the Finger Button to release a small amount of paint.

6. For background work and broad effects, hold the airbrush away from the work surface and pull back

on Finger Button to release required amount of color.

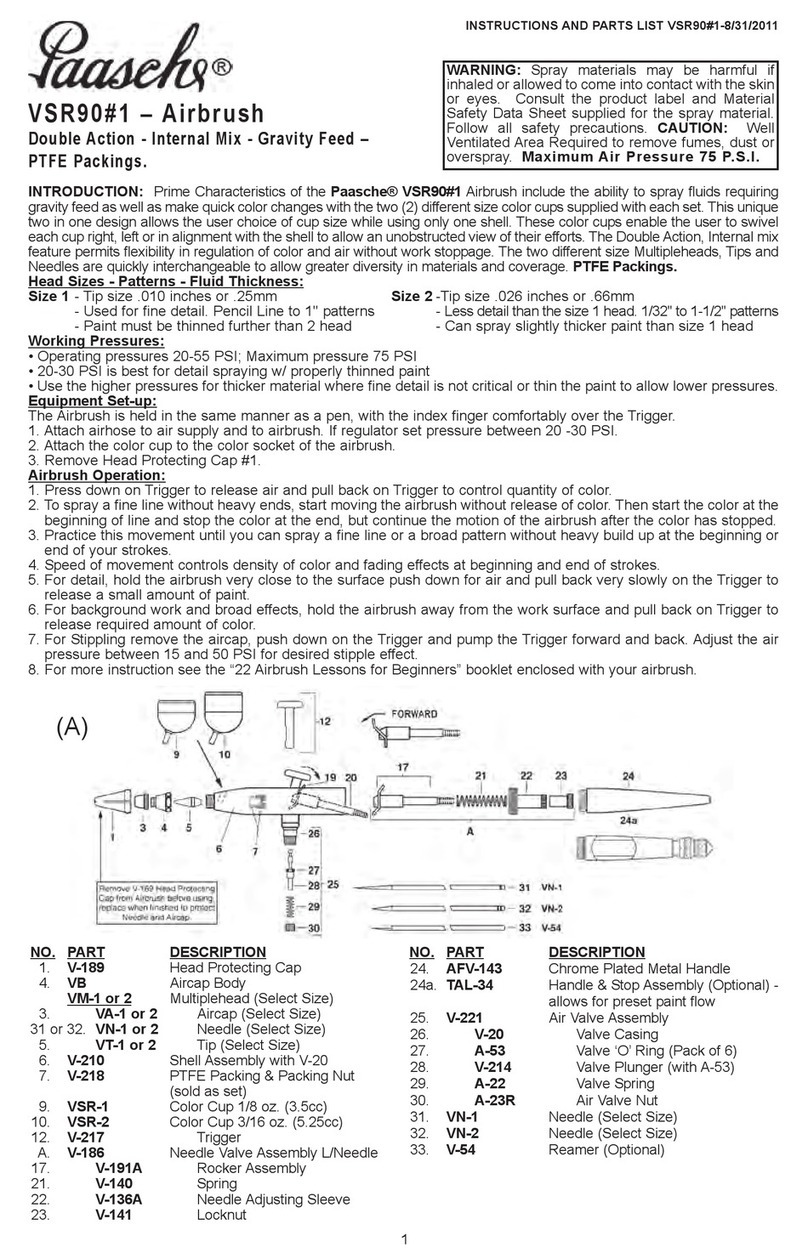

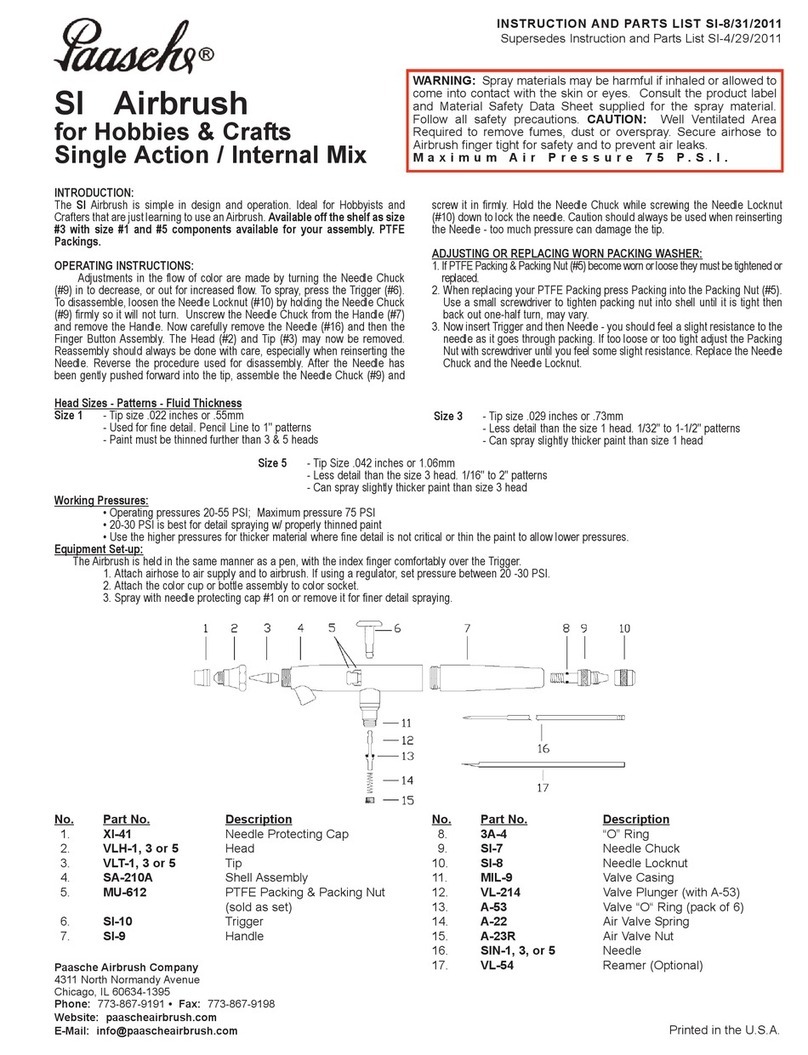

NO. PART DESCRIPTION

1. XI-41

1a. TAF-3

Needle Protection Cap

Fan Aircap for .66mm head -

2.*TA-1,TA-2,TA-3 Head(.25mm, .38mm, .66mm)

(Size TA-1 Head is used with size 0 and 1 Tip)

3.*TT-0,TT-1,TT-2,TT-3Tip(.2mm,.25mm,.38mm,.66mm)

4. MIL-12 “O” Ring for TG-30 Shell

5. TG-30 Shell Assembly

6. TG-4 Cup Cover

7. TAL-8 Packing Assembly PTFE

8. TAL-37 Trigger

9. TAL-14 Valve Casing

10. TAL-36 Valve Plunger (Includes O-ring)

10a. A-53 (Optional) Pack of (6) O-rings

11. TAL-15

11a. TAL-22

12. A-22

17. TAL-18

18. MIL-11

19. TAL-17

20. TAL-19

21. MIL-12

22. TAL-20

23. 3A-4

Valve Adapter (Includes O-ring)

(Optional) Pack of (6) O-rings

Spring

Rocker Assembly

Needle Spring

Spring Housing

Needle Lock Nut

“O” Ring

Handle

“O” Ring

*24.TN-0,TN-1,TN-2,TN-3 Needle

(.2mm,.25mm, .38mm, .66mm)

25. TAL-35 Allen Wrench

26. TAL-28 Wrench

* Note: Etched lines on items

2,3,and 24. indicate size. All

should match when installed

on airbrush.

**

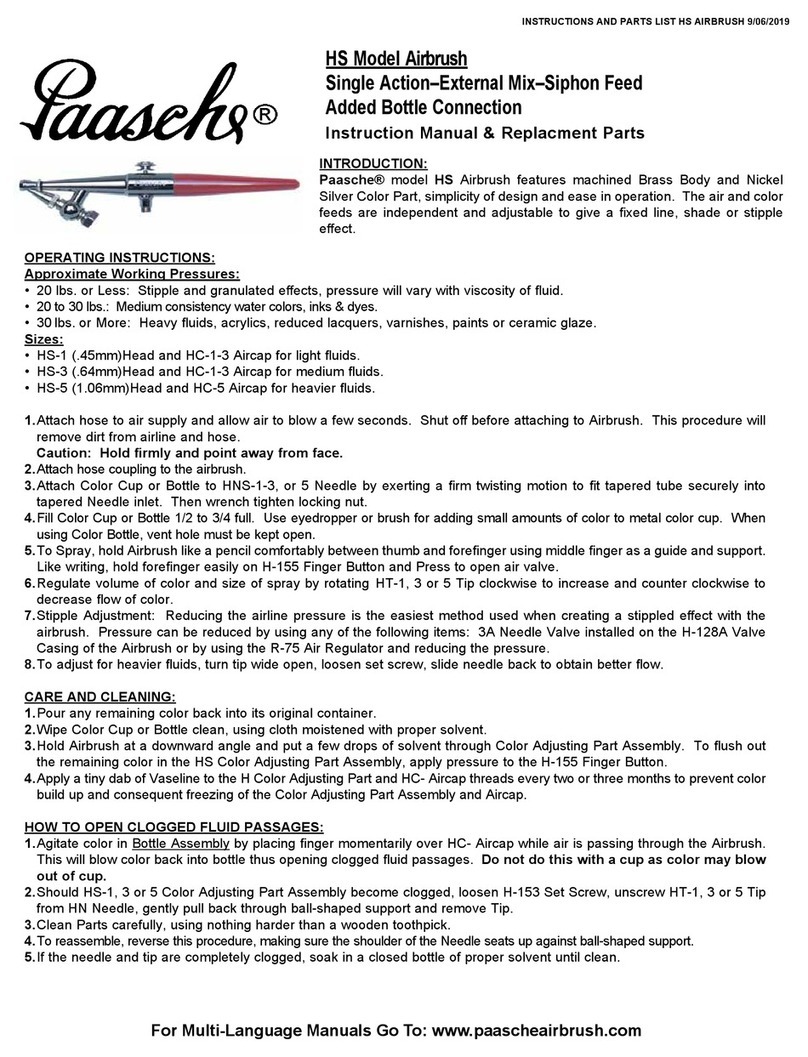

TG Talon – Airbrush

Double Action - Internal Mix - Gravity Feed - PTFE Packings.

Size #2 Needle,Tip,and Aircap Installed.

TG Specifications:

For Multi-Language Manuals go to: www.paascheairbrush.com

• Dual Action • Gravity Feed • Internal Mix • Cutaway Handle w/ Pre-set Needle Stop • PTFE Packing

•TT-2, TN-2, and TA-2 Components come installed on Talon.

.2mm head (TT-0, TN-0 and TA-1 components)Great for jobs requiring the "extremely fine"detail.

.25mm head (TT-1, TN-1, and TA-1 components)

.66mm head (TT-3, TN-3 and TA-3 components)Great for spraying Metallics, Pearlescent and Thicker Paints.

.66mm Fan Aircap (TAF-3, TN-3 and TT-3) Will give a 2-1/2 to 3 inch flat pattern.

Working pressure:

Airbrush Operation:

27. TAL-33 Needle Stop