Fine-Line Spray

1. Depress the main lever to start air flow.

2. Position the airbrush close to the surface, between 1/16 and 1/2 inch is

common.

3. Pull the main lever back slightly to start the flow of paint.

Line thickness can be controlled by adjusting the distance between the

airbrush and the surface and also by varying the paint flow by manipulating

the main lever’s position.

Wide-Line and Background Spraying

1. Depress the main lever.

2.Positiontheairbrushfurtherawayfromthesurface,from1to6inchesis

common.

3. Pull the main lever back much farther releasing more paint to cover the

bigger area.

Increasethedistancebetweentheairbrushandpaintedsurfacetocontrolthe

line’s width. Increasing the air pressure will also affect the spray width.

Air Pressure

For the NEO, working pressures generally vary between 10 and 60 psi, de-

pending onwhattypeof workisbeingdone andwhat textures are desired.

A good working

pressure may average around 15-25 psi. The viscosity of the paint and

yourdesiredspraycharacteristicswillalsoaffectyouridealpressure.Asa

generalrule,largeramountsofpaintorthickerpaints,willbesprayedwith

higher pressures.

WARNING: Do not exceed 100psi.

Paint Preparation

For non-airbrush-ready paints, proper preparation, including ltering

the paint through a nylon mesh, is recommended for best performance.

Paintshouldbethinnedwithitspropersolvent.Itisbesttopreparepaint

relatively thin and make repeated passes across the work to achieve the

desired shade. This will also improve the

quality of your work and decrease the cleaning time of your airbrush.

Safety Tips

• Always spray in a well-ventilated area.

• Do not spray solvent-based (flammable) paints around open flames.

• Use the appropriate respirator to safely lter out the paint vapors par-

ticular

to the kind of paint you are using.

• Wear eye protection to prevent paint contact with eyes.

• Never use air pressure that exceeds the airbrush’s limit (100 psi).

GENERAL OPERATION

3

Cleaning the Airbrush (TRN2)

1. Remove the paint bottle.

2. Attach a bottle containing the appropriate cleaning solution. (Note:

Medea Airbrush Cleaner works great for water-based media.)

3. Spray until the solution sprays clear.

4. Remove the bottle of cleaning solution.

5. Spray air until the airbrush sprays dry.

6. Attach a bottle containing the next color.

7. Repeat cleaning procedure when nished.

Cleaning the Airbrush (TRN1)

1. Dump out the color cup’s excess paint.

2. Rinse the cup with the appropriate cleaning solution. (Note: Medea

Airbrush Cleaner works great for water-based media.)

3. Use a paper towel to wipe out any left-over paint.

4. Fill the bottom of the cup with cleaner.

5. Spray cleaner until the spray is clear.

6. Add the next color to the color cup.

7. Repeat cleaning procedure when nished.

Cleaning the Needle (TRN2, TRN1)

Before removing the needle, clean the airbrush as recommended.

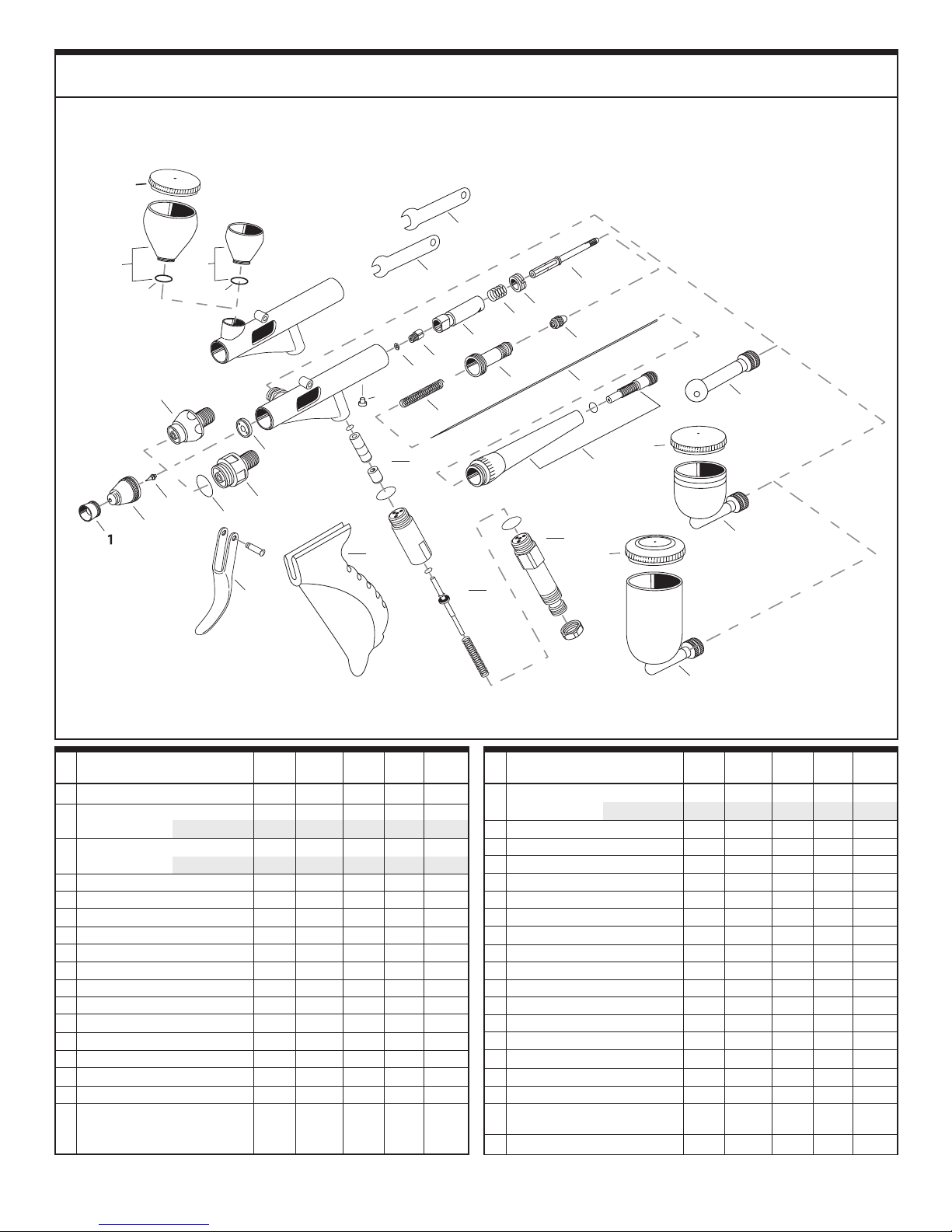

1. Unscrew the handle from the airbrush body.

2. Loosen the needle chucking nut.

3. Gently pull the needle straight out.

4. Fold a soft cloth damp with cleaner over the needle.

5. Rotate the needle to gently wipe the residual paint off.

6. Carefully insert the needle into the airbrush until it seats fully against

the nozzle.

CAUTION: The most probable time to damage the needle is when the

needlepassesthroughthemainlever. Iftheneedlestopsabruptly,retract

and examine the trigger mechanism for proper assembly and re-insert

the needle.

7. Tighten the needle chucking nut nger tight.

• Pull the main lever back and forth to visually conrm the needle’s abil-

ity to move.

8. Screw the handle back onto the airbrush body.

Before Each Session

Spraywaterortheappropriatecleaningsolutionthroughtheairbrushto

make sure the airbrush is working properly.

After Each Session

Or any time the airbrush becomes clogged:

1. Increase the air pressure.

2. Spray cleaning solution for a short time.

3. Clean the needle if necessary

Cleaning the airbrush this way helps clean the paint passage, the nozzle

and the needle thoroughly.

Periodically

To ensure smooth main lever action lubricate the needle and the main

lever

mechanism when necessary.

1. Unscrew the handle.

2. Loosen the needle chucking nut.

3. Remove the needle.

4. Coat the needle lightly at the front where the taper starts with a high-

quality

lubricant, like Medea Super Lube.

5. Wipe the needle with a soft, clean cloth, leaving a light coat of lube

behind.

6. Re-insert the needle gently into the airbrush.

7. Tighten the needle chucking nut.

8. Screw the handle onto the airbrush body.

Use atinydrop of lubeonthe mainlever’s piston. DONOT over-lube the

needle

or the main lever mechanism, since it is possible to transfer excess lube

into the nozzle causing severe paint flow problems. DO NOT use light

machineoilorWD-40forlubrication.Thesewillcausetheneedletostick

as it moves through the needle packing o-ring.

CAUTION: If it becomesabsolutely necessarytodismantle theairbrush

remember that in most situations tools are not needed.

MAINTENANCE

NEVER soak your entire airbrush in any liquid. NEVER

store your airbrush with spray medium or cleaning

agents in the uid cup.

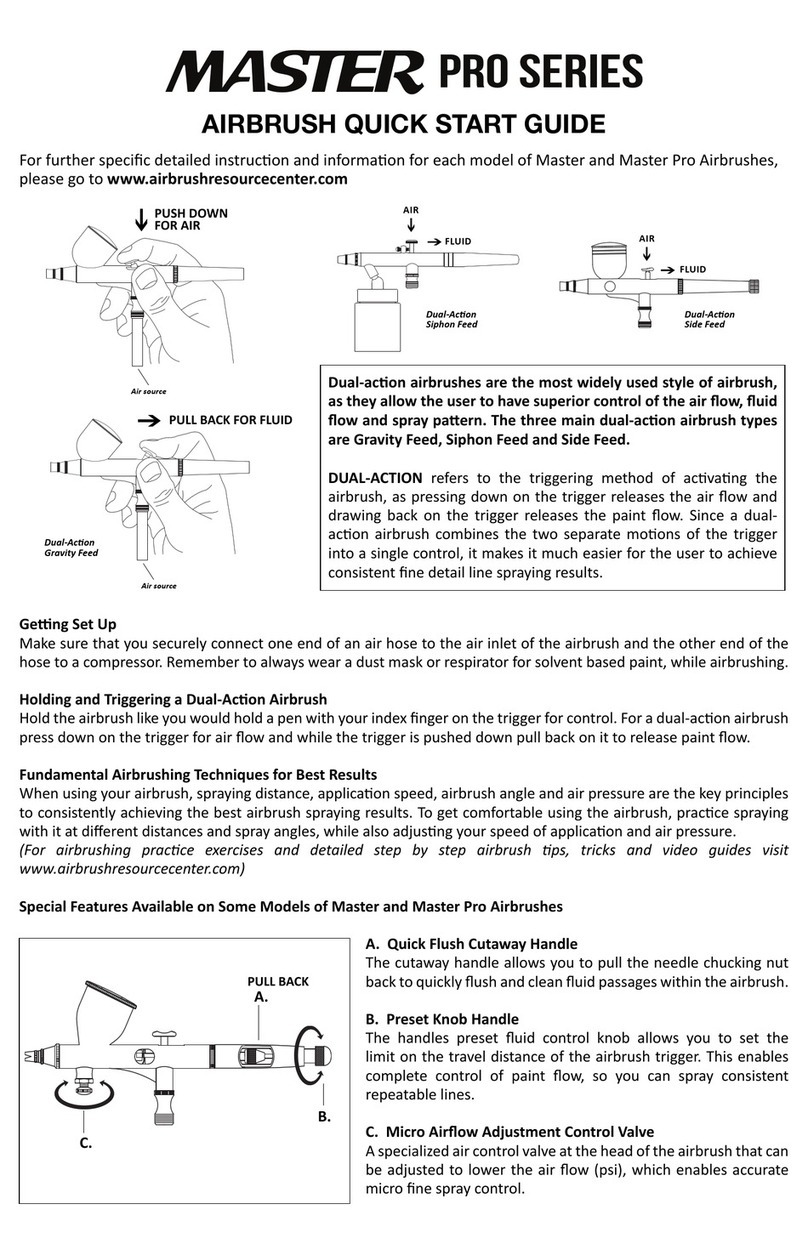

Begin by attaching the small end of an

Iwata air hose (sold separately) to your

airbrush.

Attach the other end of your airbrush

hose to an air source such as the NEO

AIR for Iwata Miniature Air Compressor

(sold separately).

Use airbrush-ready paint or be sure your paint is thinned to the

consistency of skim milk. Thicker paint may require spraying at a

higher psi.

BEGIN

1

PAINT

2

TO AIR SOURCE

Quick Start Guide

For further in-depth instruction and information, please go to

www.iwata-neo.com

For the gravity-feed NEO CN, remove lid by pulling o. Put a few drops of paint

into the color cup and push lid back on. (Note you have 2 choices of cup size).

For the siphon-feed NEO BCN, put paint into the Big Mouth Bottle (included)

and attach the bottle to the bottom of the airbrush by pushing it into the

airbrush. (Bottle does not screw in.)

IMPORTANT NOZZLE INFORMATION

SIPHON-FEED NEO

BIG MOUTH BOTTLE

GRAVITY-FEED NEO

PAINT

PAINT

LID

はじめに

塗料

吸上式NEO

付属ボトル

重力式NEO

塗料

塗料

フタ

Never remove the nozzle unless it is damaged or clogged.

Always keep your airbrush clean. Never leave paint in your airbrush as dried paint can

clog a nozzle. Although engineered from durable, high-quality materials, the nozzle is

small and delicate. Accidental damage caused by cross-threading, over-tightening,

dropping the airbrush, forcing a needle or tools into the nozzle and normal wear are

not covered under the warranty. Replacement parts and repair services are available

through your local aliate.

1

2

エアー源へ

ノズルについての大切なお知らせ

詰まりや 損 傷 が な い 限りはノズ ルを取り外 さな いでください 。

常にエアーブラシをきれいに保ってください。塗料が乾くとノズルが詰まってしまいま

すので、塗料がエアーブラシに残らないようにしてください。丈夫で高品質な材料か

ら作られていてもノズルは小さくデリケートな部品です。過度の締め付け、落下、ニー

ドルやツールの無理な挿入、ネジ山の損傷など不注意による損傷および消耗は保証

の対象外です。部品の交換や修理サービスなどについては現地のアネスト岩田グル

ープ各社までお問合せください。

クイックスタートガイド

詳細は下記のホームページからご確認いただけます

www.iwata-airbrush.com/links-manuals.html

エアーブラシにエアーホース(別売り)

の片方を繋いでください。

エアーホースのもう片方を、エアーブ

ラシ用ミニコンプレッサ(別売り)など

のエアー源へ繋いでください。

塗料はエアーブラシ用塗料を使用するか、牛乳程度まで薄めてくだ

さい。粘度の高い塗料は吹付けに高めの圧力が必要となります。

重力式NEO CNは、フタを外してカップに数滴塗料を入れて、フタを戻してくだ

さい。(カップのサイズは2タイプ ありま す )

吸上式NEO BCNは、付属のボトルに塗料を入れて、ボトルをエアーブラシ下部

に差し入れてください。(ボトルはネジ式ではありません)