JABLOTRON ALARMS a.s.

Pod Skalkou 4567/33 46601 Jablonec n. Nisou

Czech Republic www.jablotron.com

||

|

JA-151IR wireless 4beam optical barrier

JA-151IR wireless 4beam optical barrier 1 / 2 MMY51904

The JA-151IR four-beam infra-red optical barrier is designed for the indication

of a breach into a protected area by crossing the IR line between the transmitter

and the receiver. The barrier is a product SL-350QFR by Optex supplemented

with transmitters JA-150TX-V4 produced by JABLOTRON ALARMS compatible

with the JABLOTRON 100. The device is equipped with a 4-ray optical part with

a high immunity against false alarms and the detection of small animals.

The barrier occupies two positions in the system. The transmitters regularly

perform automatic tests and report their status to the system. The barrier should

be installed by a trained technician with a valid certificate issued by an authorised

distributor.

Barrier installation

The following instructions should be observed when selecting a place for

barrier installation:

Both units must be installed on a stationary construction (e.g. a wall

or a thick post) at the same height and should face each other.

The area between the barrier units must not be blocked by any bushes

or tall grass.

There can be up to a 100 m distance between the units indoors.

(The distance could be reduced outdoors.)

The receiver unit must not be affected by direct sunlight.

The units should be installed 0.7 – 1 m above the ground.

If the IR beam is parallel to a wall, there must be at least a 1 m distance

between the beam and the wall.

If multiple barriers are used, it is necessary to avoid influencing the beam

of one barrier by another barrier

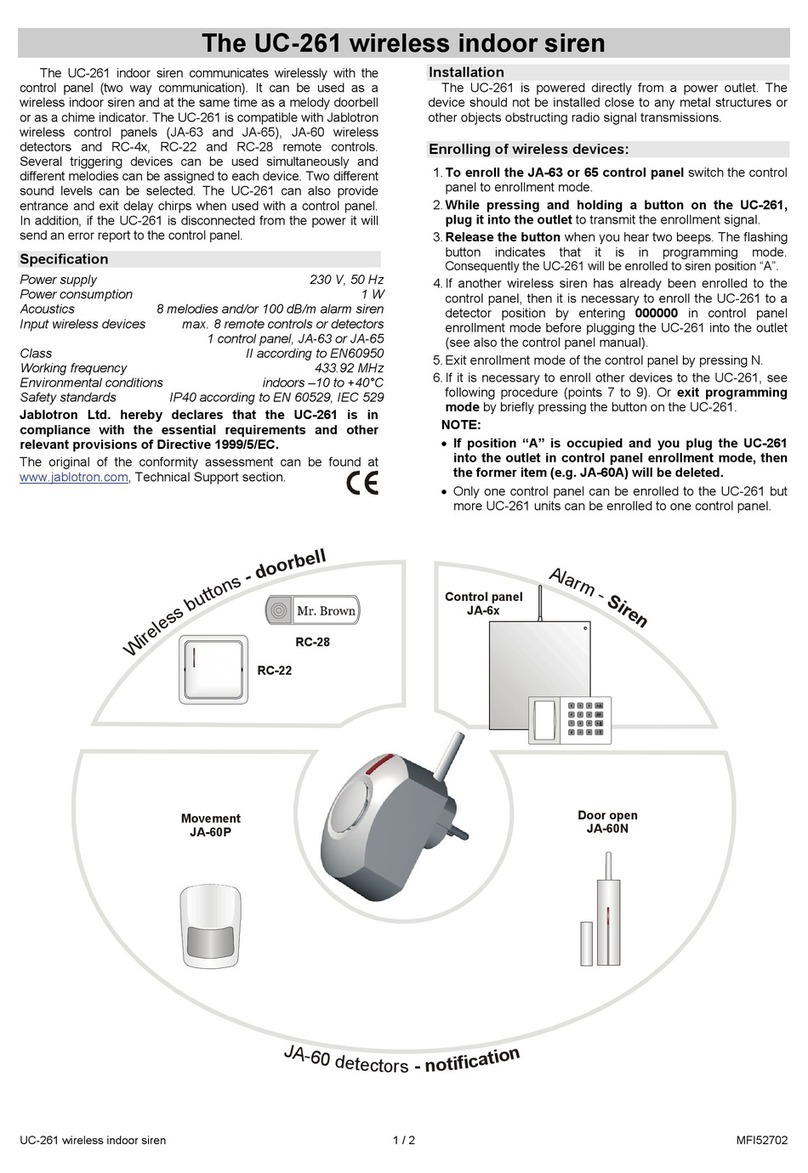

Fig. 1: Undesirable locations

Installation steps:

The transmitting unit (marked TRANSMITTER) and the receiving unit

(marked RECEIVER) are of identical mechanical construction.

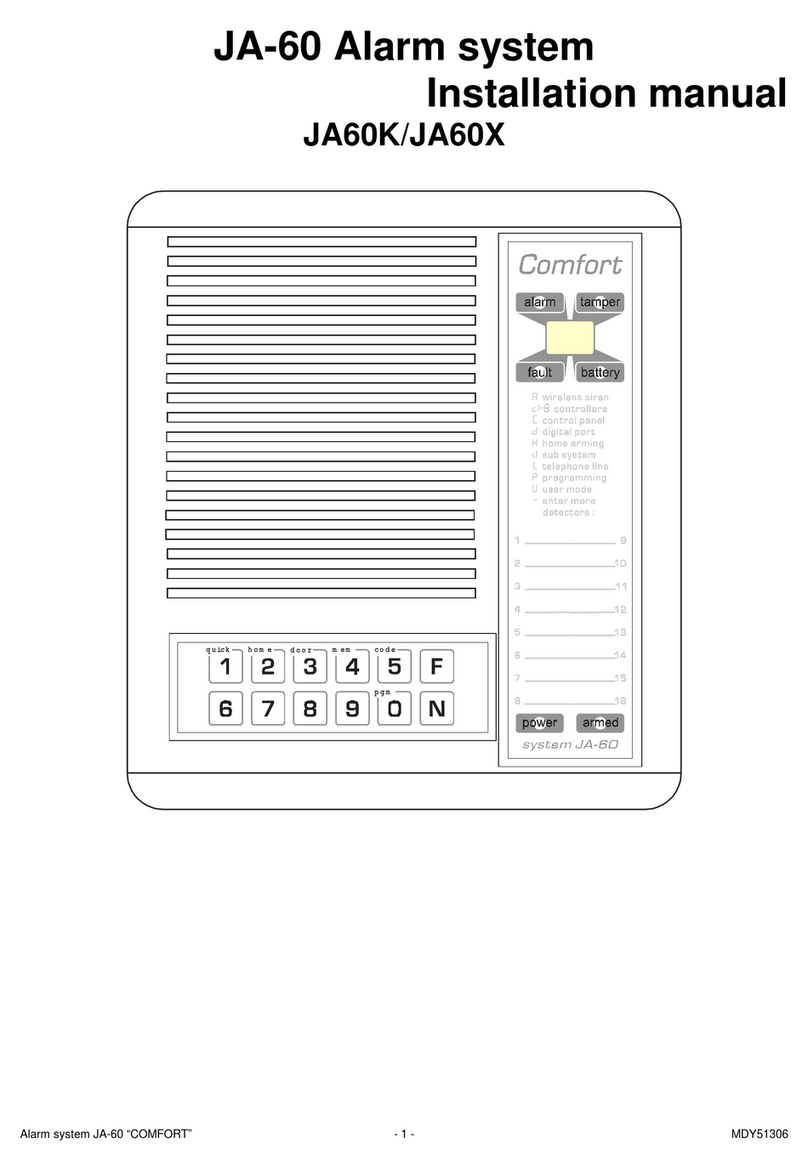

Fig. 2 Barrier parts (identical for transmitter and receiver): A – Front barrier

cover, B – Main unit, C – Base of the unit, D – Rear cover, 1 – The locking

screw of the front cover, 2 – Viewfinder for barrier alignment, 3 – Optical

part, 4 – Setting of optical viewing angle, 5 – Screws for main unit fixing,

6 – Battery holders, 7 – Jablotron transmitter

1. Unscrew the front cover screw (1) and remove it. Use a coin inserted

between the thresholds of the plastic parts to get it out and carefully take

it off by a prying motion.

2. Take away the main unit with the base (B+C) by releasing the 4 screws

(5) in the corner of the base unit (C). Then take the base of the unit away

from the rear cover (D).

3. Install the rear cover (D) onto the selected place, either directly onto a

wall or a post. On the rear plastic case holes are pre-pressed for

installation on the wall (WALL) or for a pole (POLE).

4. The Jablotron transmitter (7) and battery holders (6) are placed inside

the rear cover (D). Everything is connected to the main unit by a coloured

wiring harness with connectors. The connectors are unmistakable.

Enrolling the barrier transmitters into the

system

The radio transmitters for communication with the JABLOTRON 100

system are placed inside the rear cover (D) underneath the optical part

of the detector. The barrier occupies 2 positions in the system.

Barrier activation is reported by the receiving part of the barrier. Both barrier

parts report tampering and battery status.

For powering each unit always use a minimum of two SAFT LSH20

lithium batteries (they are not included in the package). The correct

position of the batteries is marked inside the holder. Mind the correct

polarity during insertion. Four batteries can be inserted into the receiver and

transmitter as well. This prolongs the barrier operational time.

1. Enrol the radio transmitter to the system.

a. There must be a JA-11xR radio module installed in the system.

b. Go to the F-Link software, select the required position in the

Devices window and launch the enrolment mode by clicking on the

Enrol option.

c. Insert the batteries (mind the correct polarity). The enrolment signal

is transmitted when the first battery is inserted into the detector

and the device is enrolled to the selected position.

2. Screw on the base (C) and main (B) unit.

3. Do the barrier optical alignment according to the following chapter.

4. Screw on the cover and test the barrier functioning.

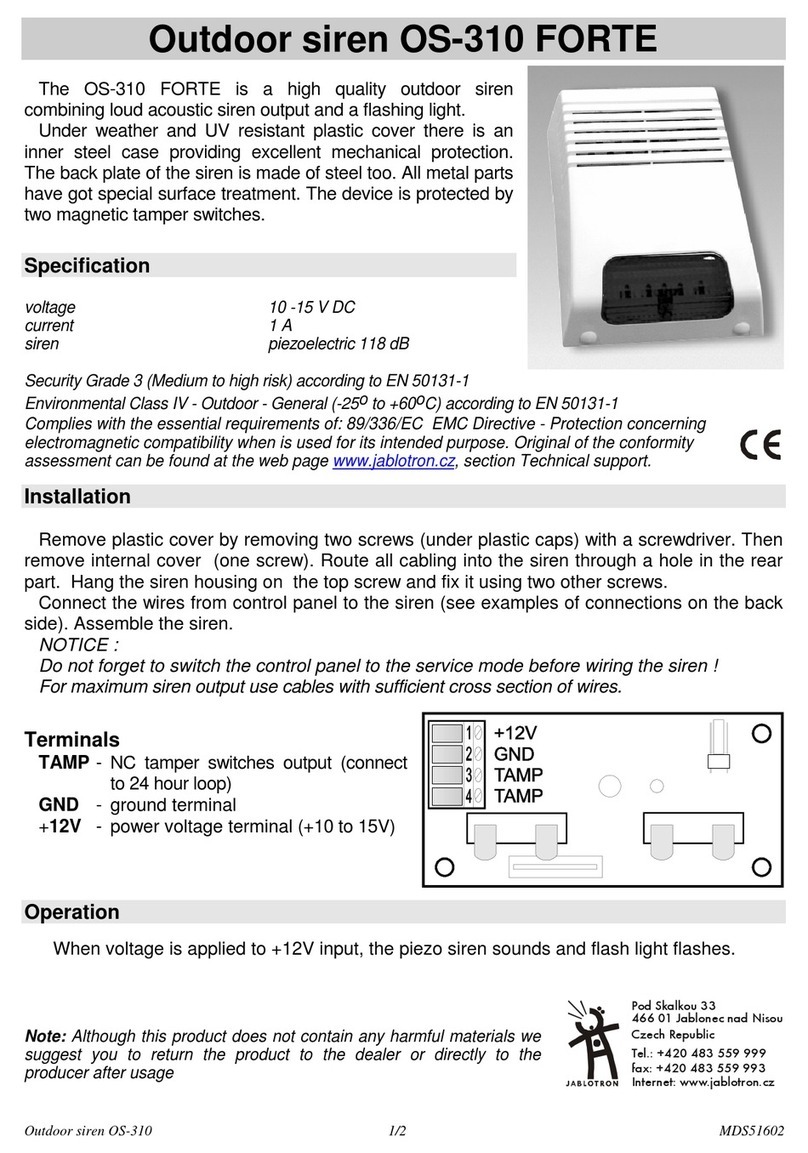

Receiver

N.C. N.O.

Status (INP) Pulse (INP)

AUX Fault AUX Antimasking

Not used

Transmitter

N.C. N.O.

Status (INP) Pulse (INP)

AUX Fault AUX Antimasking

Not used

Factory settings highlighted by bold letters.

Fig. 3 Radio transmitter JA-150TX-V4 (matched transmitter and receiver):

1 – terminals, 2 – option DIP switch (factory pre-set), 3 – external tamper

connector, 4 – external antenna jumper, 5 – external antenna connector

If needed the transmitter can be equipped with an AN-868 (2PIN)

external antenna connected to the connector (5) and disconnect

the jumper (4).

Setting up the optical part of the barrier

Always perform the detector settings and beam alignment when

the tamper contact is blocked. The optical part of the barrier must

be adjusted so that the optical parts facing each other are physically

aligned. Both units are equipped with adjusting elements for the adjustment

of direction and a view-finder for precise adjustment. The unit opposite

the one you want to adjust must be in the centre of the aiming cross and

the cross must be in the centre of the view-finder (see fig. 4). There are

optical covers placed inside the front barrier covers. Slide the cover on the

lower optical part and perform the upper optical part setting then repeat the

procedure for the lower part of the optics. If it is needed to test the barrier

function with a closed front cover it is possible to lock the tamper contact by

a rotating plate to avoid physical closing of the barrier. The rotating plate

is placed next to the tamper contact.

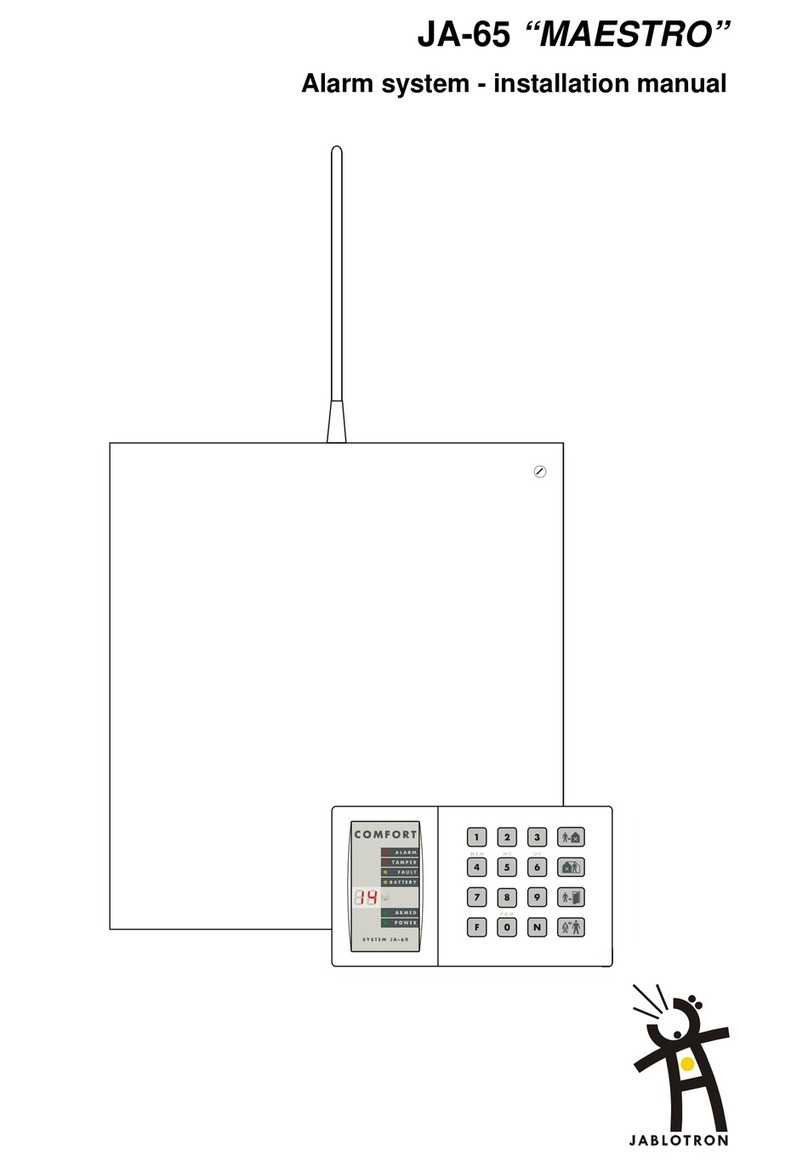

Fig. 4: Setting up the optical part

1234

ON

1234

ON