Generally the pulse width of the pulse generator circuit is controlled by the range key selectors on

the front panel at the display unit. Three different pulse lengths: 0.08usec, 0.3usec and 0.8usec (in

accordance with the range scale) can be provided. The pulse repetition frequency (PRF) always

changes automatically

to

match the selected operating pulse length (See TABLE 1

).

Upon receiving the positive trigger pulse, TR5 generate a differential waveform at C35, R39-R44

setup the discharge period of this waveform

to

generate a short (80ns), medium (300ns), or long

(800ns) gate to ICl-6. The pulse is amplified and applied to the gate

of

TR14 that will conduct for the

selected pulse length drawing current through the primary

of

the Pulse Transformer (T2) generating a

1.

85kV pulse to the magnetron cathode.

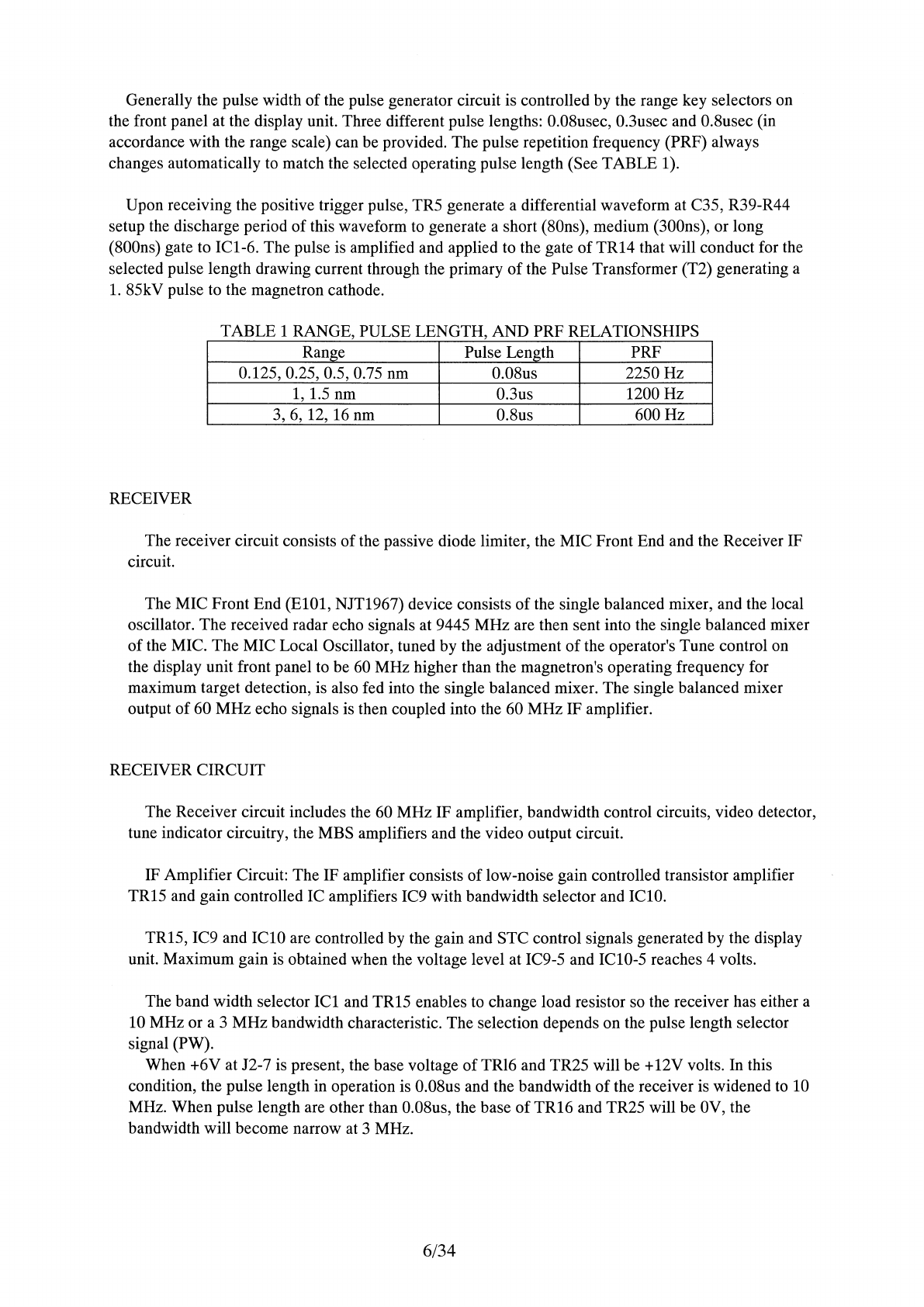

TABLE 1 RANGE, PULSE LENGTH, AND PRF RELATIONSHIPS

Range Pulse Length PRF

0.125, 0.25, 0.5, 0.75 nm 0.08us 2250 Hz

1,

1.5 nm 0.3us 1200 Hz

3,

6,

12, 16 nm 0.8us

600Hz

RECEIVER

The receiver circuit consists of the passive diode limiter, the MIC Front End and the Receiver IF

circuit.

The MIC Front End

(ElOl,

NJT1967) device consists

of

the single balanced mixer, and the local

oscillator. The received radar echo signals at 9445 MHz are then sent into the single balanced mixer

of the MIC. The MIC Local Oscillator, tuned by the adjustment of the operator's Tune control on

the display unit front panel to be

60

MHz higher than the magnetron's operating frequency for

maximum target detection, is also fed into the single balanced mixer. The single balanced mixer

output

of

60 MHz echo signals is then coupled into the 60 MHz IF amplifier.

RECEIVER CIRCUIT

The Receiver circuit includes the 60 MHz IF amplifier, bandwidth control circuits, video detector,

tune indicator circuitry, the MBS amplifiers and the video output circuit.

IF Amplifier Circuit: The IF amplifier consists oflow-noise gain controlled transistor amplifier

TR15 and gain controlled IC amplifiers IC9 with bandwidth selector and IClO.

TR15, IC9 and IClO are controlled by the gain and STC control signals generated by the display

unit. Maximum gain is obtained when the voltage level at IC9-5 and ICl0-5 reaches 4 volts.

The band width selector

ICl

and TR15 enables

to

change load resistor so the receiver has either a

10 MHz or a 3 MHz bandwidth characteristic. The selection depends on the pulse length selector

signal (PW).

When +6V at J2-7 is present, the base voltage of

TR16

and TR25 will be +12V volts. In this

condition, the pulse length in operation is 0.08us and the bandwidth

of

the receiver is widened

to

10

MHz. When pulse length are other than 0.08us, the base

of

TR16 and TR25 will be 0V, the

bandwidth will become narrow at 3 MHz.

6/34