Jason International, Inc. • 501.771.4477 Page 5 of 16 Customer Service : 800.255.5766

Copyright © 2014 Jason International

INSTALLATION INSTRUCTIONS (cont.)

ELECTRICAL

Electrical Power Supply: These instructions are written as-

suming 60Hz, 120v power supply. Special notations are also

included for export versions of the equipment and power supply.

WARNING: Verification of electrical requirements MUST

be made before installation. Refer to the equipment labels

for voltage and frequency requirements.

NOTE: The bath is designed for indoor use only. The

electrical equipment must not be exposed to direct or indirect

water or moisture contact. The electrical equipment must

also be protected from dust and other airborne debris before,

during, and after installation.

1. Electrical Service: A licensed electrician must provide

the “dedicated” electrical service protected by a GFCI. The

location of the GFCI must be at least five (5) feet (152cm)

away from the inside surface of the bath, accessible for

regular testing. Use copper conductors only.

DANGER — RISK OF ELECTRIC SHOCK: Connect only

to a circuit protected by a Ground Fault Circuit Interrupter

(GFCI). In the unlikely occurrence of a current imbalance

in the power conductors, the GFCI will interrupt the power

to the bath.

WARNING: The electrical service to the GFCI must not

be interrupted by any control device. Likewise, the electri-

cal service from the GFCI to the bath control should be

direct and not interrupted by a switch. Never use a switch

in conjunction with a control device. This will VOID THE

MANUFACTURER’S WARRANTY.

2. GROUNDING IS REQUIRED

The unit should be installed by a qualified service

representative and properly grounded.

3. I N S TA L L S E R V I C E CO N N EC T I O N AT L E A S T 6" (15 c m)

ABOVE SUB FLOOR.

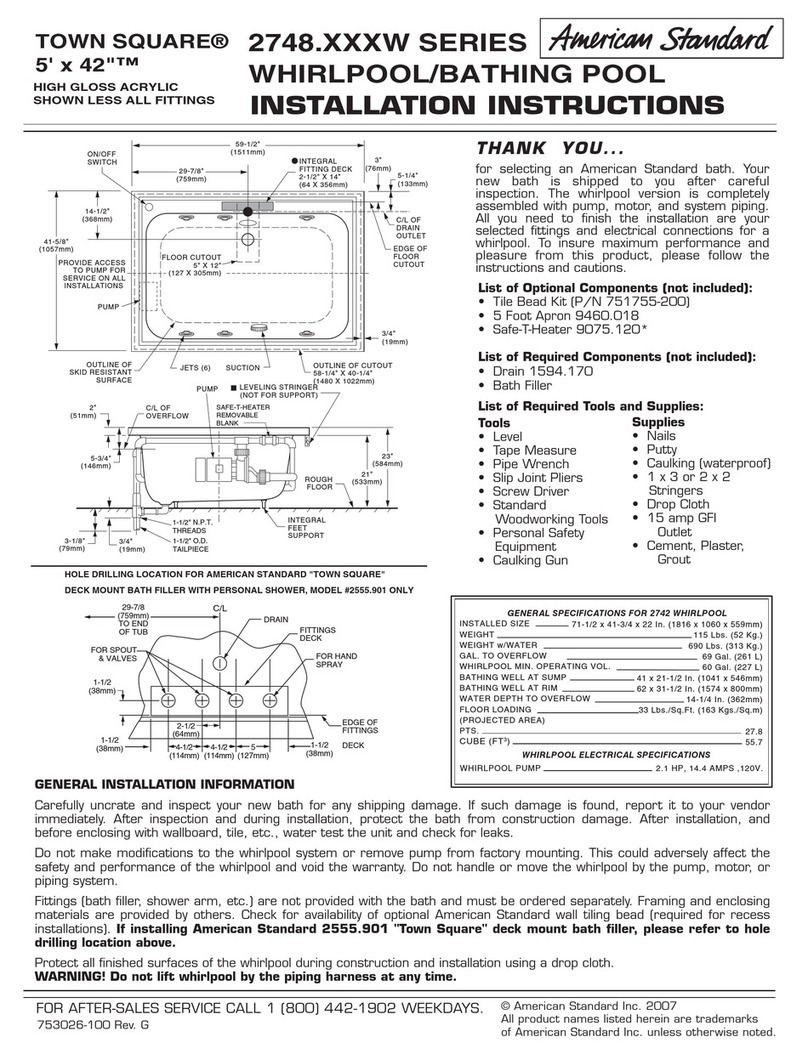

ALL LOCAL AND STATE ELECTRICAL AND PLUMB-

ING CODES MUST BE OBSERVED. Where there are

no local codes, the National Electric Code (NEC) and

Uniform Plumbing Code (UPC) shall be observed.

It is the responsibility of the installer/owner to determine

specific code compliance prior to installation of the

product.

NOTE:IntheCommonwealthofMassachusetts,installation

is to be done by a Massachusetts licensed plumber.

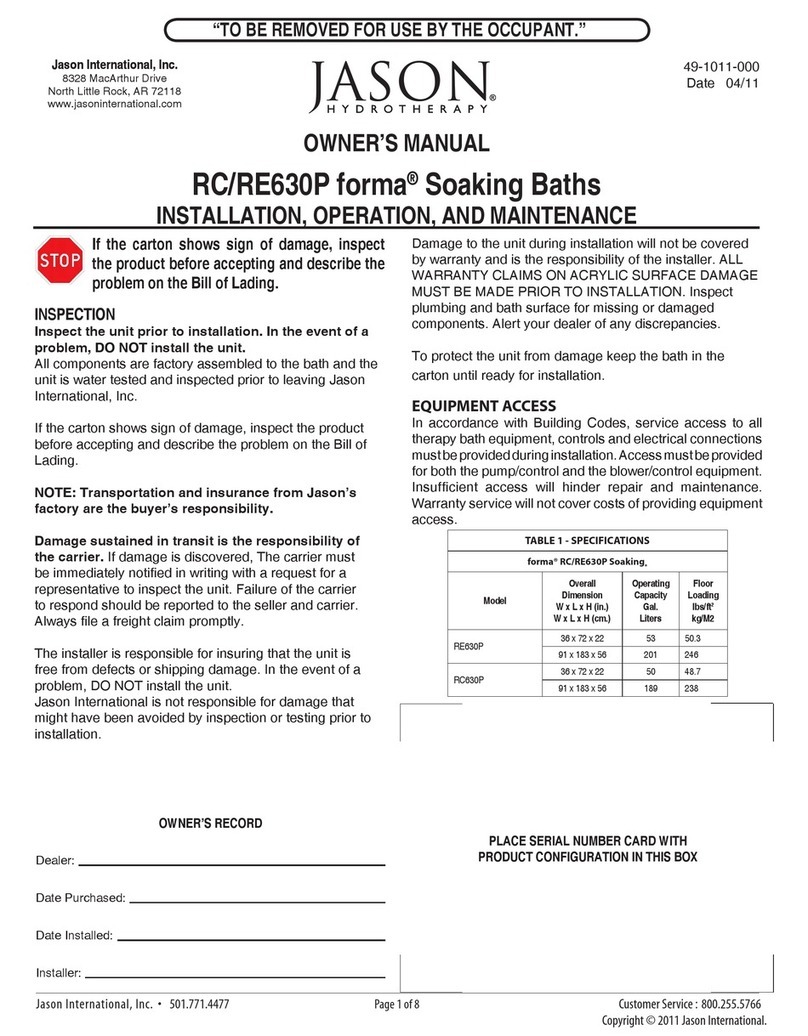

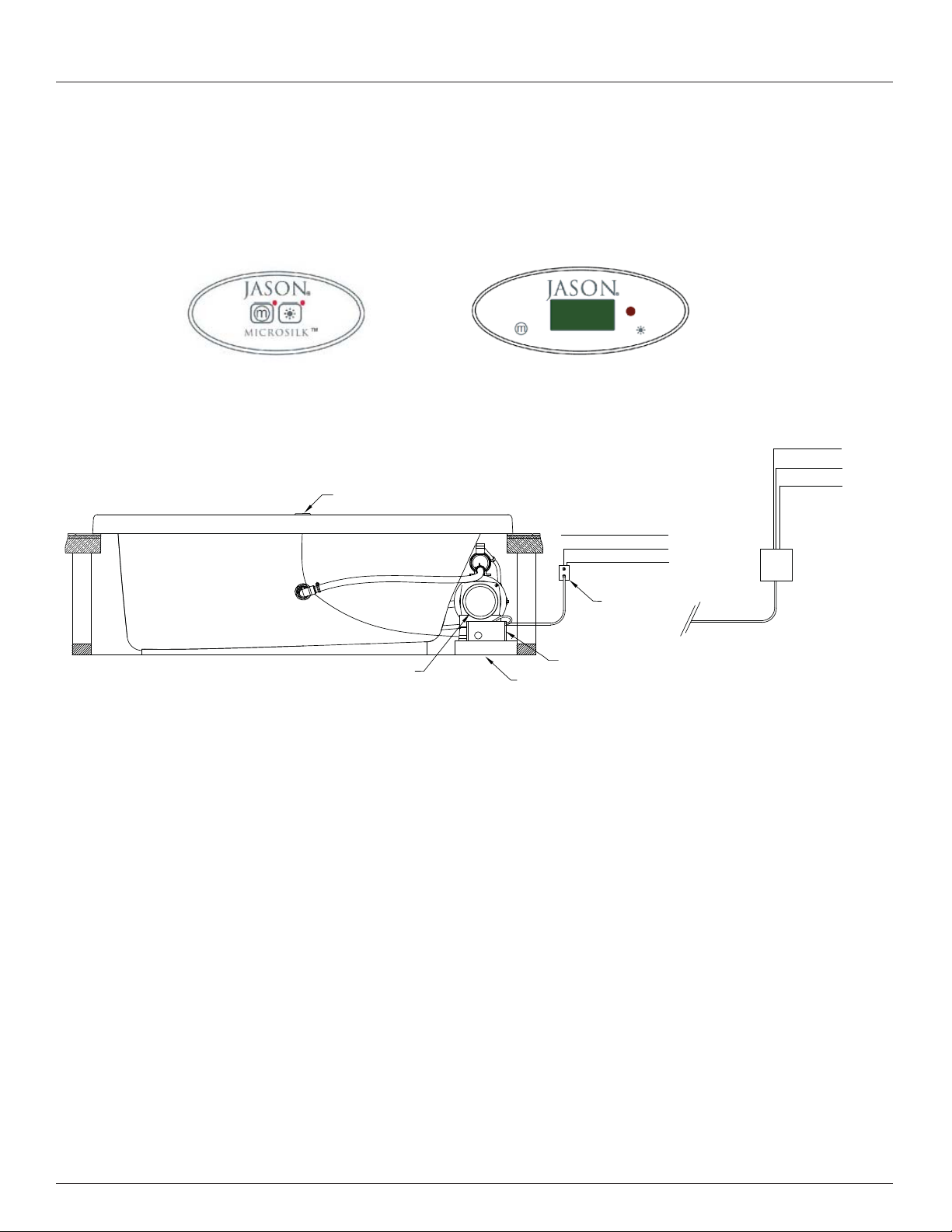

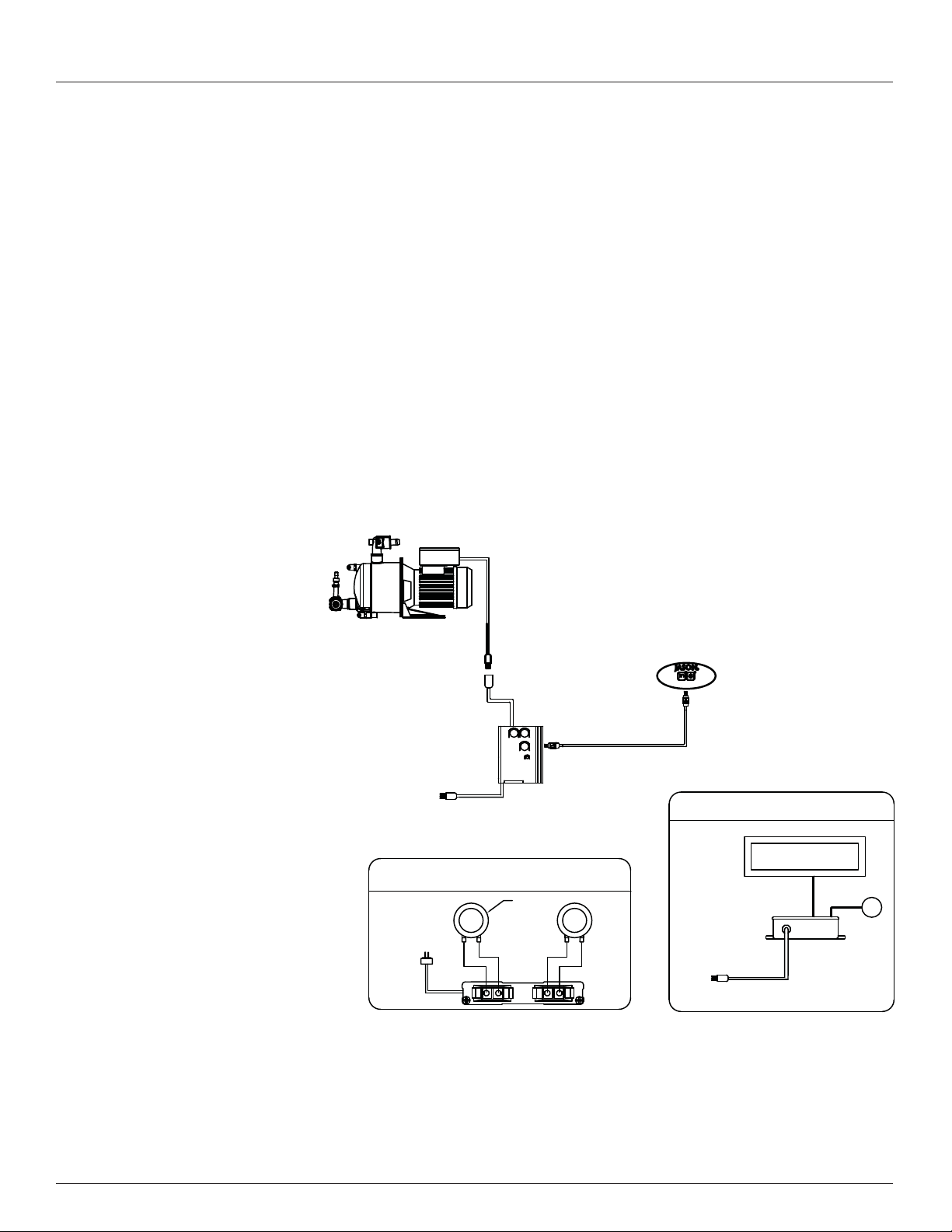

4. 120V Electrical Service- MicroSilk®Control Box.

TheMicroSilk®generatorunit may beshipped separatefrom

the bath. Follow the instructions for the MicroSilk®Pump

Assembly Field Installation in the Installation section of

this owner’smanual (instructions arealso packagedwiththe

MicroSilk®unit packaging). Thecontrolboxhas a36" (91cm)

cord with plug end. The MicroSilk®control box is mounted

on a stand that is temporarily secured to the packing board

for shipping. During installation, the control box bracket

and controls must be positioned horizontally and located

to permit access for inspection and servicing. If the Micro-

Silk®generator unit is shipped separate from the bath, the

MicroSilk®pump’s power cord will need to be plugged

into the control box. Connect the pump’s male NEMA

plug to the female NEMA plug of the control box’s

load line. The MicroSilk control must be plugged into

a dedicated 120V, 20A, 60Hz, GFCI protected circuit

(See Figure 8).

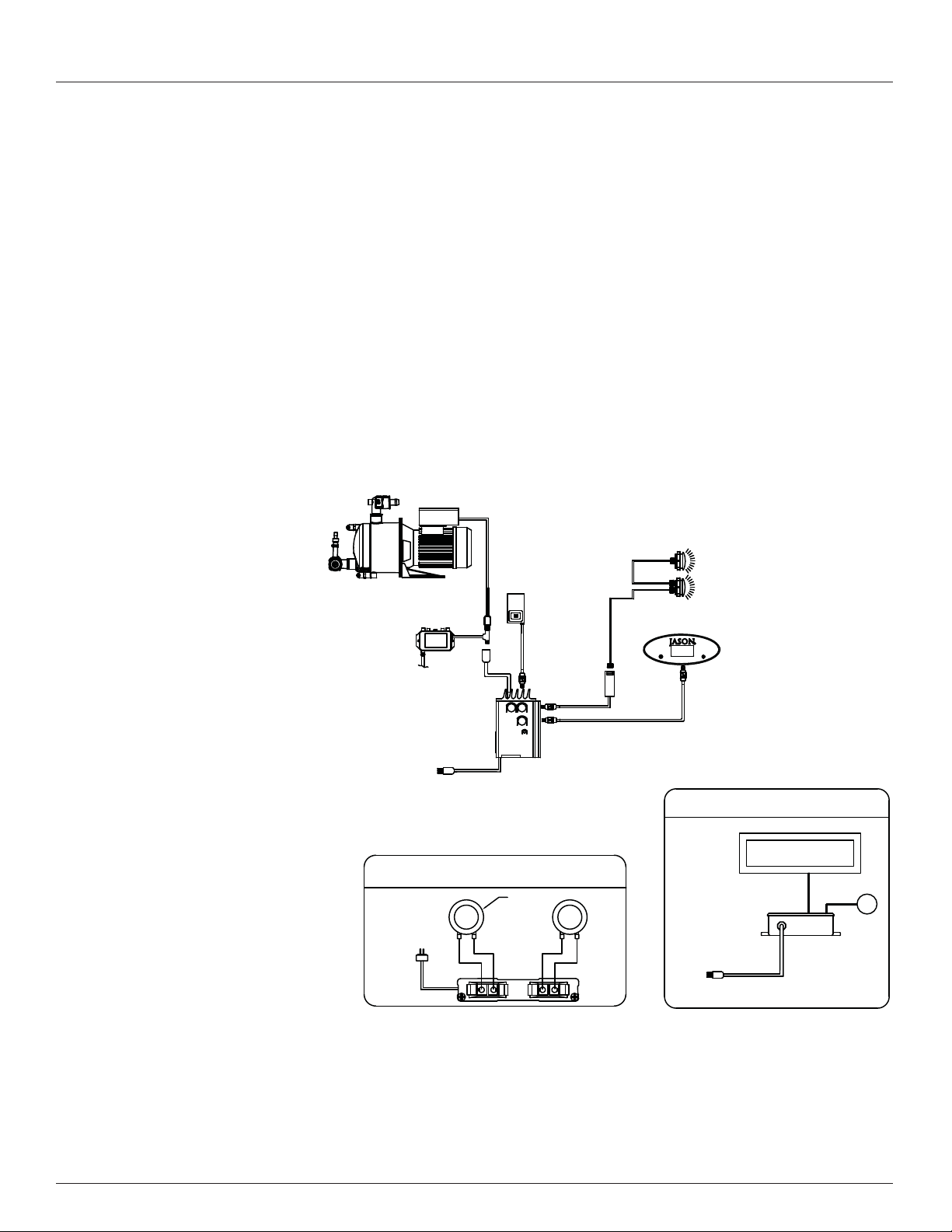

5. 240VElectricalService-MicroSilk®Control Box (Export).

TheMicroSilk®generatorunit may beshipped separatefrom

the bath. Follow the instructions for the MicroSilk®Pump

Assembly Field Installation in the Installation section of

this owner’smanual (instructions arealso packagedwiththe

MicroSilk®unit packaging). Thecontrolboxhas a36" (91cm)

cord with a junction box connection. The MicroSilk®control

box is mounted on a stand that is temporarily secured to the

packing board for shipping. During installation, the control

boxbracketand controlsmust bepositioned horizontallyand

located to permit access for inspection and servicing. If the

MicroSilk®generator unit is shipped separate from the

bath, the MicroSilk®pump’s power cord will need to be

plugged into the control box. Connect the pump’s male

J+J plug to the female J+J plug of the control box’s load

line. The MicroSilk®control must be plugged into a dedi-

cated 240V,vffgdg 20A, 50 or 60 Hz, GFCI protected circuit

(See Figure 8).

DANGER: Do not alter the factory installed wiring. All

building materials and wiring should be routed away from the

equipment or other heat-producing components of the unit.