Javo Quickfiller Manual

Version 2011-4-1 Page 2

Contents

Introduction ........................................................................................................................................................ 1

General information ............................................................................................................................................ 4

Supplier information..................................................................................................................................................... 4

Intended use ................................................................................................................................................................. 4

Non-recommended use ................................................................................................................................................ 4

Conditions of use .......................................................................................................................................................... 4

Description of the machine........................................................................................................................................... 4

Operating principle ....................................................................................................................................................... 5

Workstations at the machine........................................................................................................................................ 5

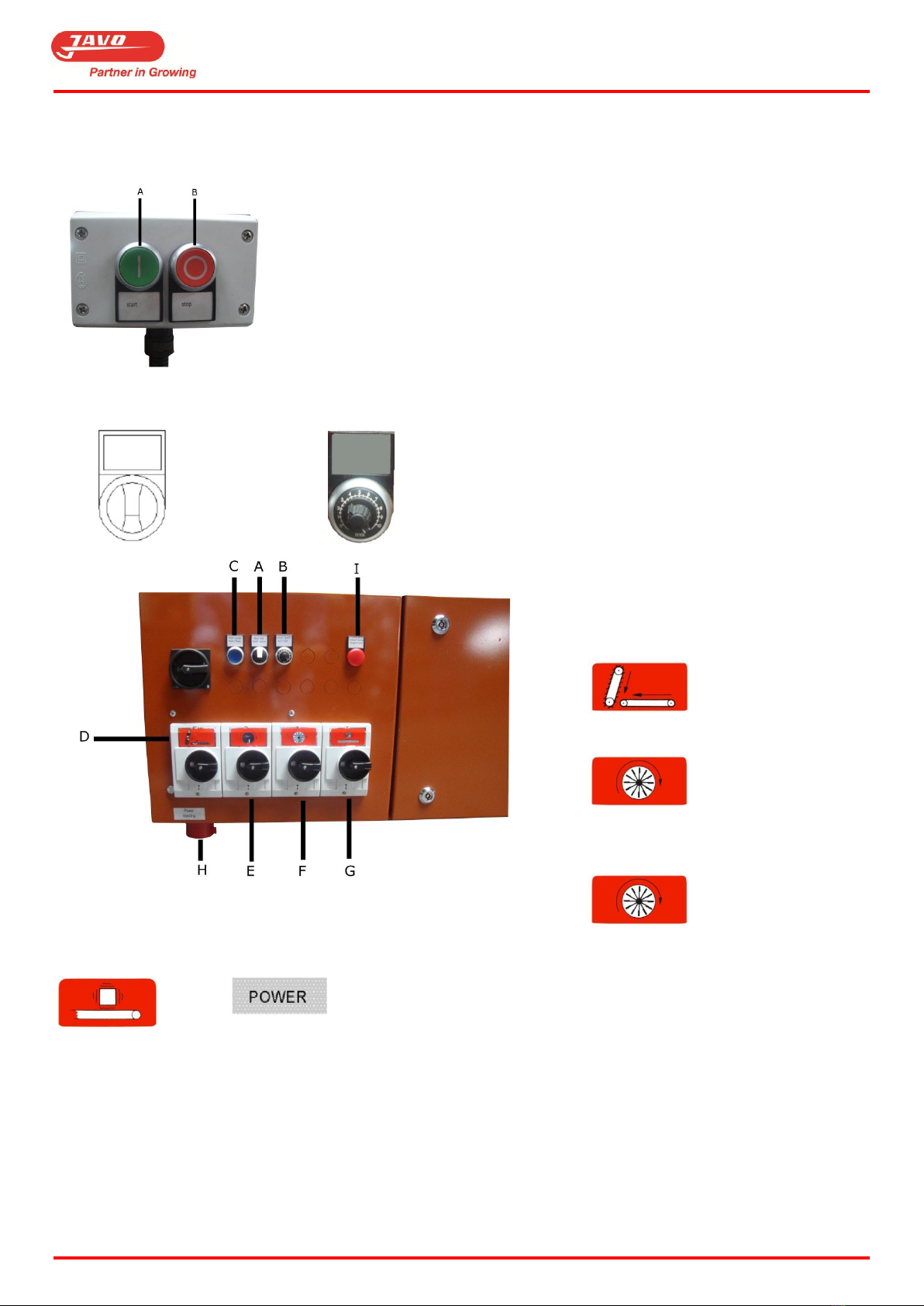

Controls......................................................................................................................................................................... 6

Safety .................................................................................................................................................................. 7

Use of personal safety equipment................................................................................................................................ 7

Important safety factors ............................................................................................................................................... 7

Safety precautions ........................................................................................................................................................ 7

Safety features on the machine.................................................................................................................................... 7

Safety precautions ........................................................................................................................................................ 7

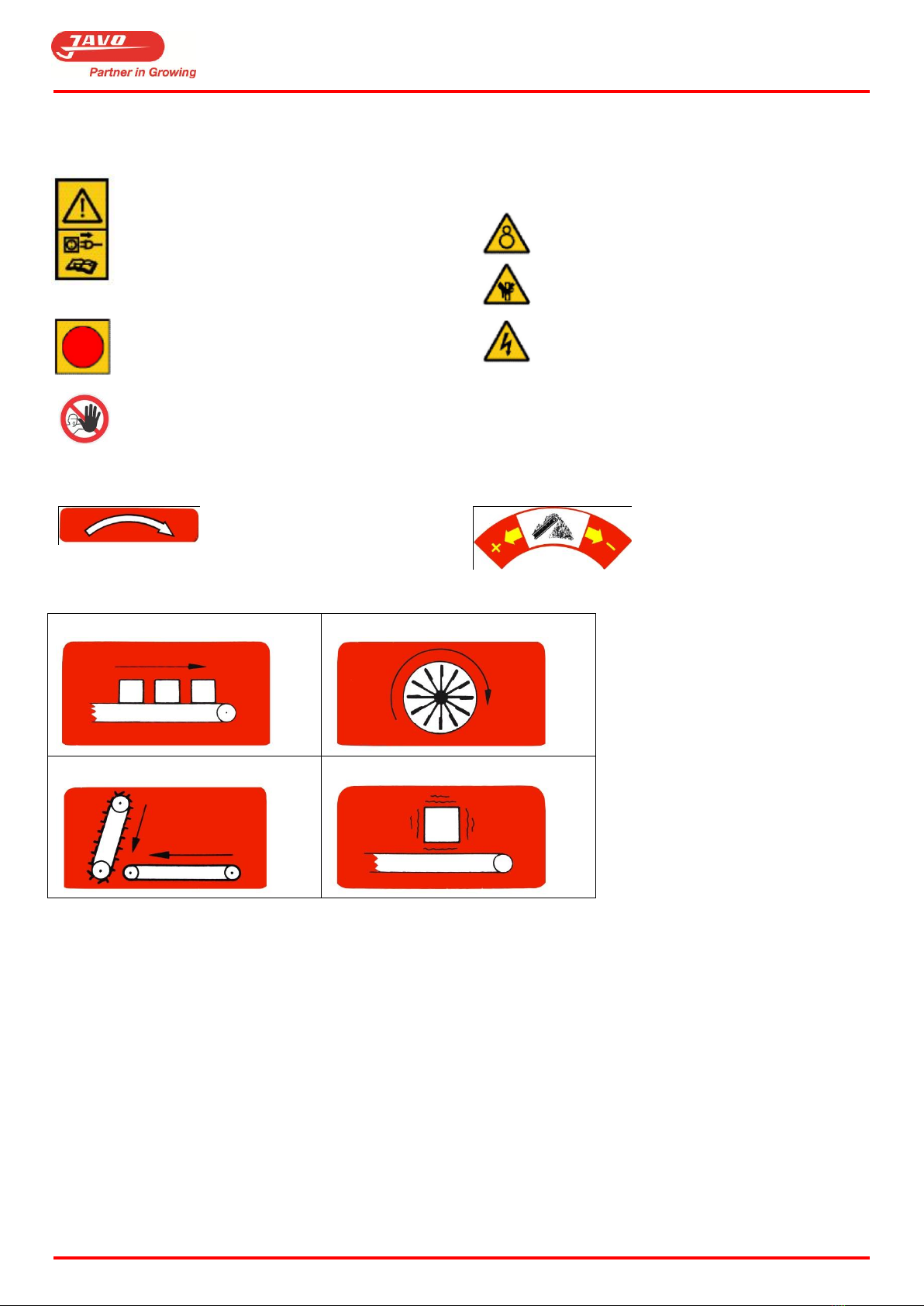

Explanation of the symbols on the machine................................................................................................................. 8

Assembly, installation and commissioning............................................................................................................ 9

Location......................................................................................................................................................................... 9

Assembly / connection.................................................................................................................................................. 9

Setting-up / adjusting.................................................................................................................................................... 9

Covers and doors ...................................................................................................................................................... 9

Type of soil ................................................................................................................................................................ 9

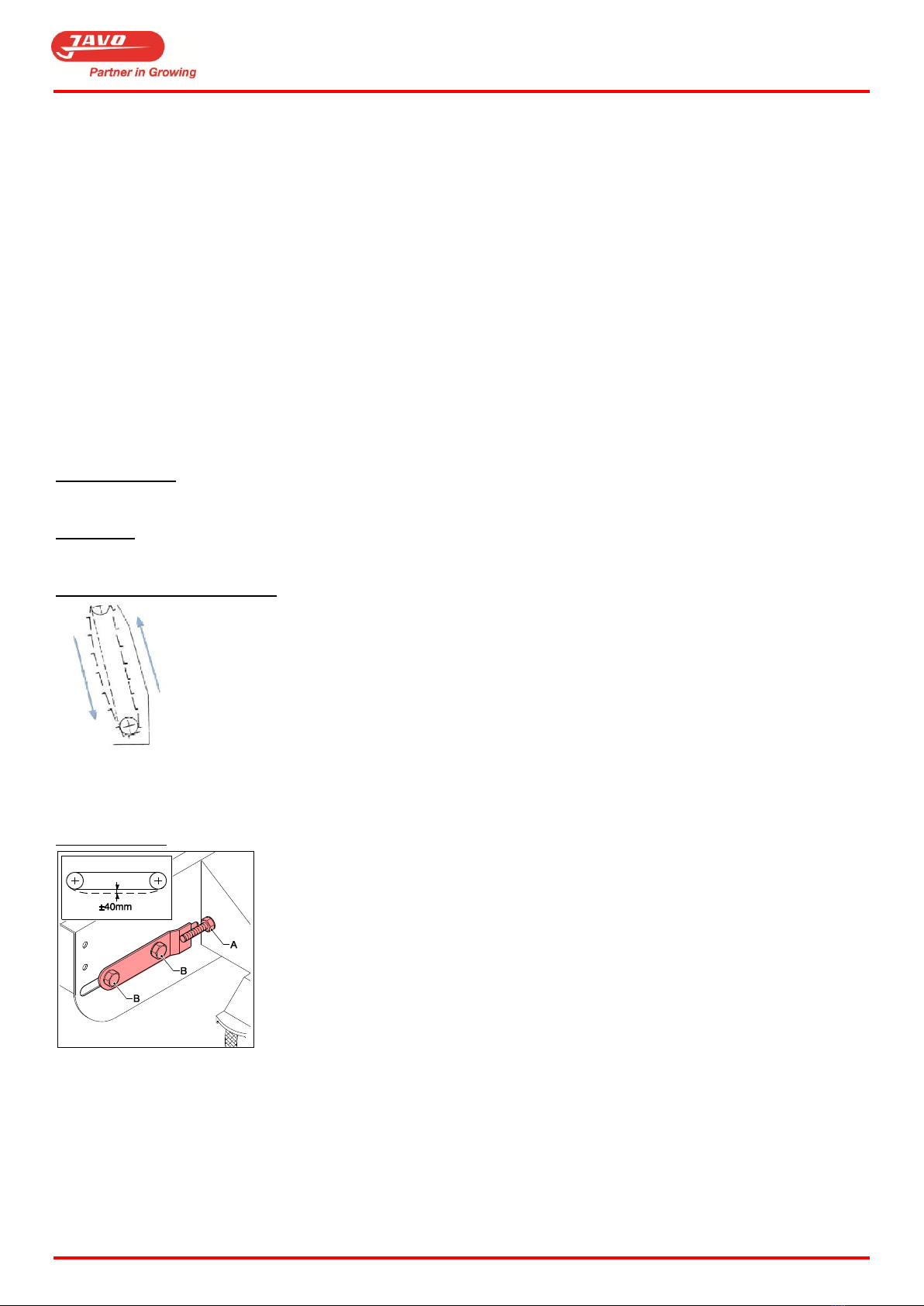

Elevator direction of movement............................................................................................................................... 9

Soil belt tension......................................................................................................................................................... 9

Elevator chain tension............................................................................................................................................. 10

Facilities to be provided by the user........................................................................................................................... 10

Operation .......................................................................................................................................................... 11

Setting-up and adjustments........................................................................................................................................11

Type of soil ..............................................................................................................................................................11

Soil elevation conveyor speed ................................................................................................................................11

Conveyor belt speed adjustment............................................................................................................................11

Rotor height ............................................................................................................................................................11

Brush height ............................................................................................................................................................ 12

Soil plate in the soil bin...........................................................................................................................................12

Tray levelling height................................................................................................................................................12

Soil guide plates ...................................................................................................................................................... 13

Starting, normal operation, stopping, emergency stop.............................................................................................. 13