7

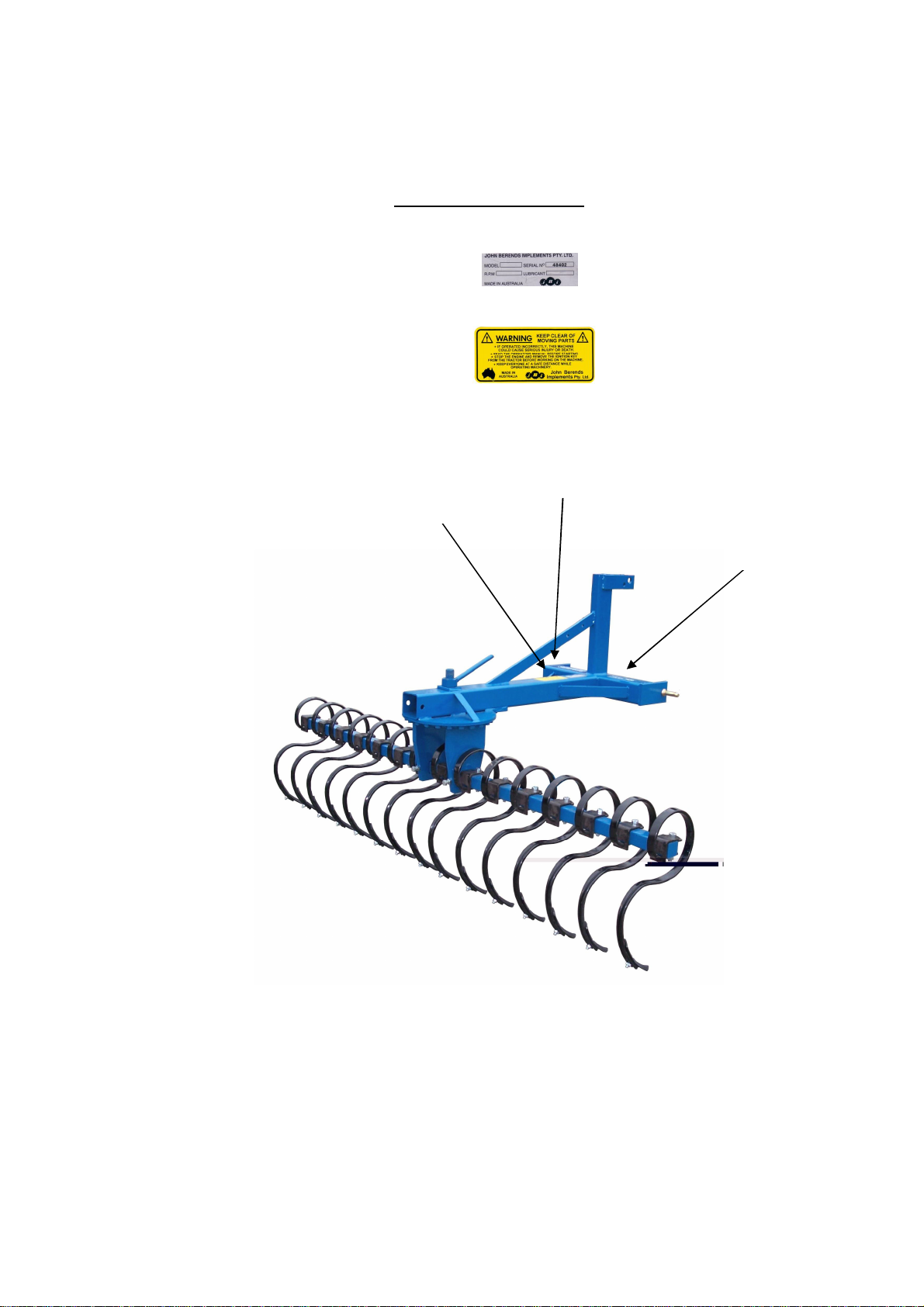

ASSEMBLY

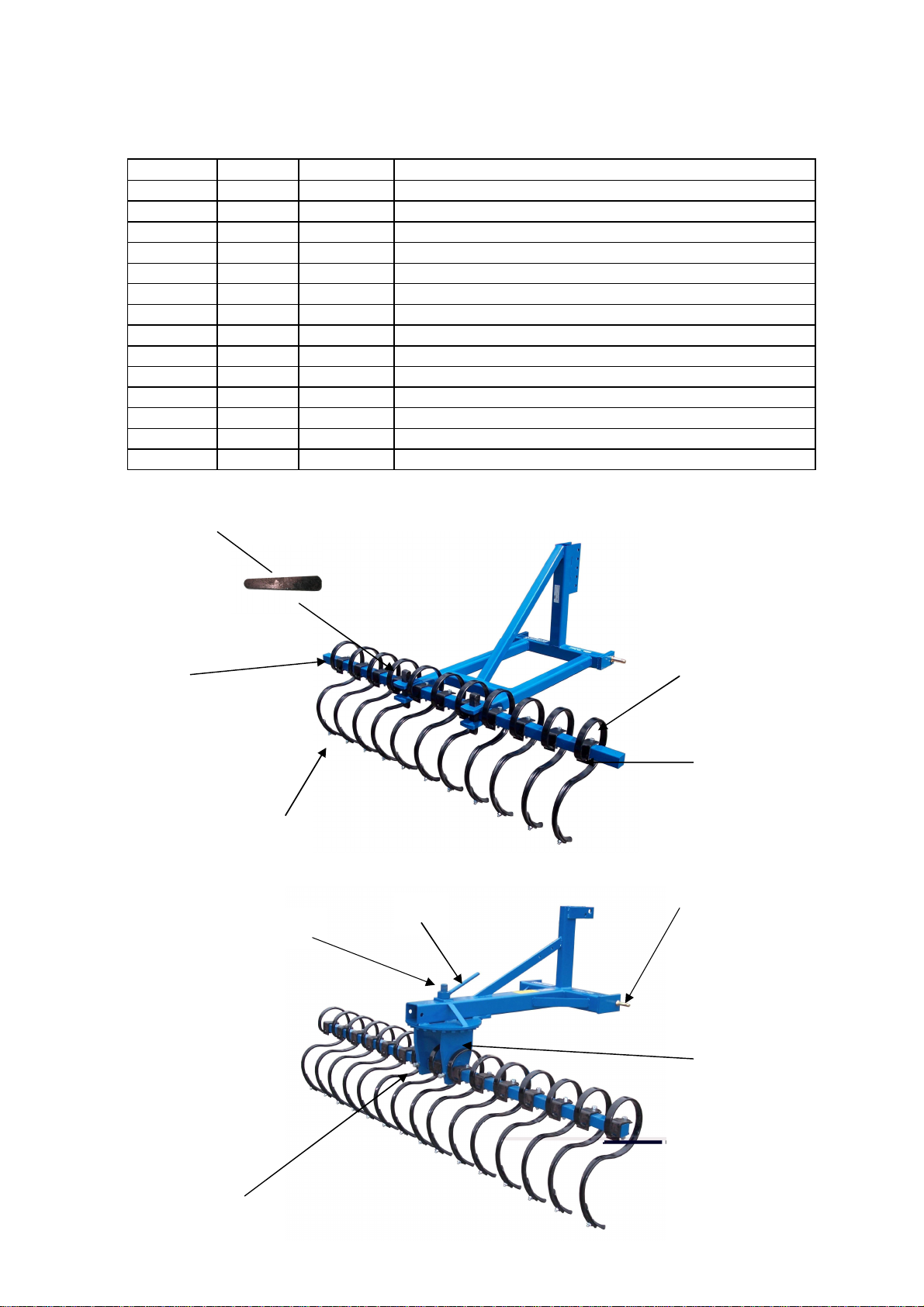

Line the lower linkage arms between the lower linkage plates of the stick rake top, slide the

linkage pins through the holes and secure with linch pins. Attach the top link to the stick rake. It

may be helpful to support the linkage at the right height with a stable block or similar. Sway

chains or bars should be used to prevent the machine swinging around in use.

OPERATION

Once all safety procedures have been followed, start the tractor and raise the stick rake off the

ground

There are four positions of offset on either side of the rake (except for the standard fixed and

toolbar models). The offset adjusting arm has to be mounted on the side on which the rake is

required to be offset, left for left and right for right. It is adjusted by fitting the pin at the rear

end of the adjusting arm in one of the four alternative holes in the beam. To do this level the

machine so it will not swing around under its own weight, then remove the pin, move the rake

beam across until the hole in the offset arms lines up with a hole in the beam at the desired

offset.

The second adjustment is the angle. The rake is locked in position by a locking lug under the

beam and is held tight by the pivot nut handle. Loosen the handle so that the rake drops below

the locking index. This is best done by lifting the machine slightly off the ground using the

linkage arms on the tractor. Rotate the rake to the desired angle and ensure the angle

adjustment handle (nut handle) is secure. Apply some grease to the pivot pin to prevent it from

seizing up over time.

Always have the stick rake tines facing straight forward when operating to prevent tine

damage. You will only need to adjust the angle when altering the offset position.

Caution:

When adjusting any stick rake angle or offset, make sure the machine is level so it will not

swing around under its own weight.

The toolbar type can also be offset simply by knocking out the wedges holding the bar inside

the clamps and relocating the toolbar to one side. Knock the wedges back in with a hammer to

ensure they lock the toolbar inplace.

The offset model will tilt via the linkage pins. When connecting the stick rake, position the

tractors lower linkage arms in different holes to vary the tilt. The rake can be tilted from the

tractor using the levelling box without altering the pins. There are probably not many situations

where a stick rake will use a tilt function however it is still incorporated in the unit in case a

grader blade is mounted at any stage.

Caution:

Only operate the stick rake on even ground. If ground is undulating it is advised that depth

wheels be mounted on either side to prevent excessive force on outer tines.