5

JBL Professional Control 200 Series

Control 200 Series Loudspeakers include Euroblock or

Phoenix-type locking input connectors that allow the system

to be “pre-wired” before the speakers are installed.

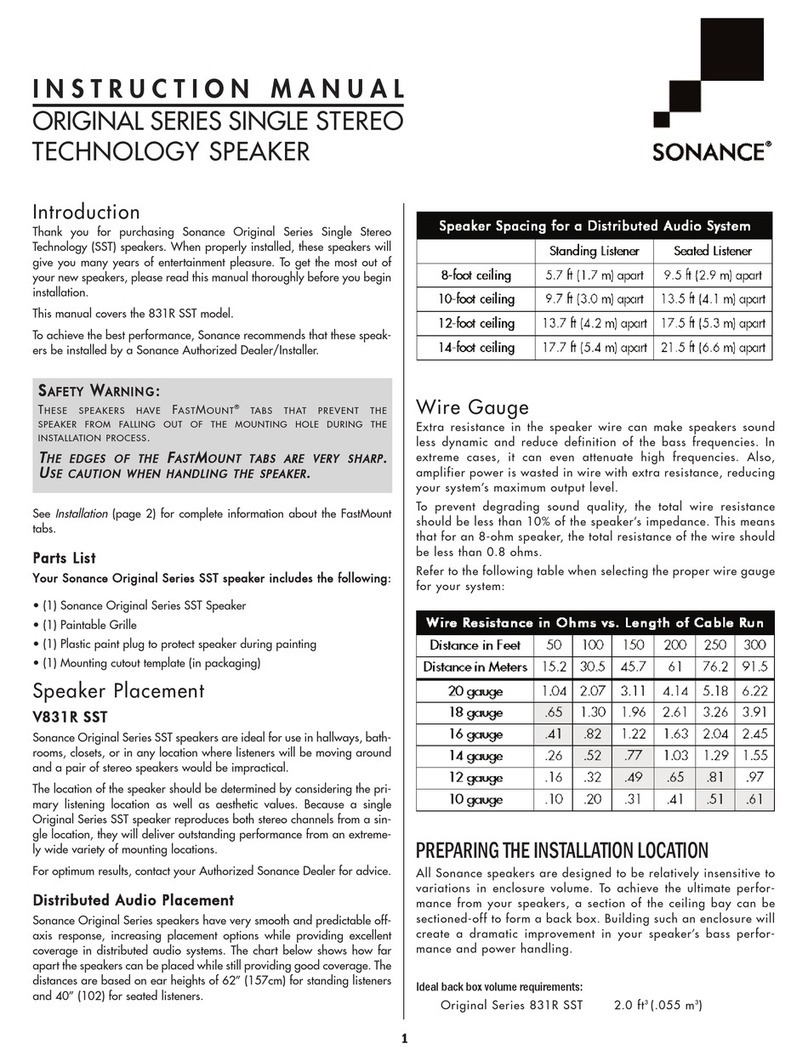

Connecting the Wiring to the Euroblock -- Connect the

wiring to the removable locking connector

that is INCLUDED with the speaker by

stripping the insulation back about 5 mm

(about 3/16 inch), inserting the bare end of

wire into the connector and screwing down

the hold-down screw until tight using a small

flatblade screwdriver. Tighten any unused

screws to avoid vibration. Using terminal

block connectors allows the system to be pre-

wired before final installation of the drivers.

When wiring Control 200 Series loudspeakers,

always use proper electrical wiring practices

in accordance with your area’s building codes

and regulations.

Control 226C/T

Connecting the Input Terminal Block on the Control

226C/T -- The input terminal cover on the Control 226C/T

is fitted with a conduit connector for running and securing

wiring or conduit to and from the unit. To wire the unit:

1. Loosen the screw on top of the input terminal cover and

then remove (and save) the input terminal cover screw on

the side of the can.

2. Swing open the input terminal cover and remove the

euroblock connector.

3. Insert the bare end of wire into the euroblock connector

and secure the wires with the hold-down screws. (see

Connecting the Wiring to the Euroblock)

4. Loosen the conduit

connector on the input

terminal cover and insert

the wired euroblock

connector through the

conduit connector opening.

Connect the euroblock to

the matching receptacle.

5. Shut the input terminal

cover and replace and

tighten the terminal cover screws.

6. Allowing sufficient strain relief for the input wiring and re-

tighten the conduit connector on the terminal cover.

NOTE: The input terminal

cover on the Control 226C/T

also includes a .75 in (19 mm)

knockout for an additional

conduit clamp. This knockout

point can be used in addition

to the conduit connector

located on the top of the can

and is useful for wiring loop-

thru runs or when access

is limited on the top of the

Control 226C/T can.

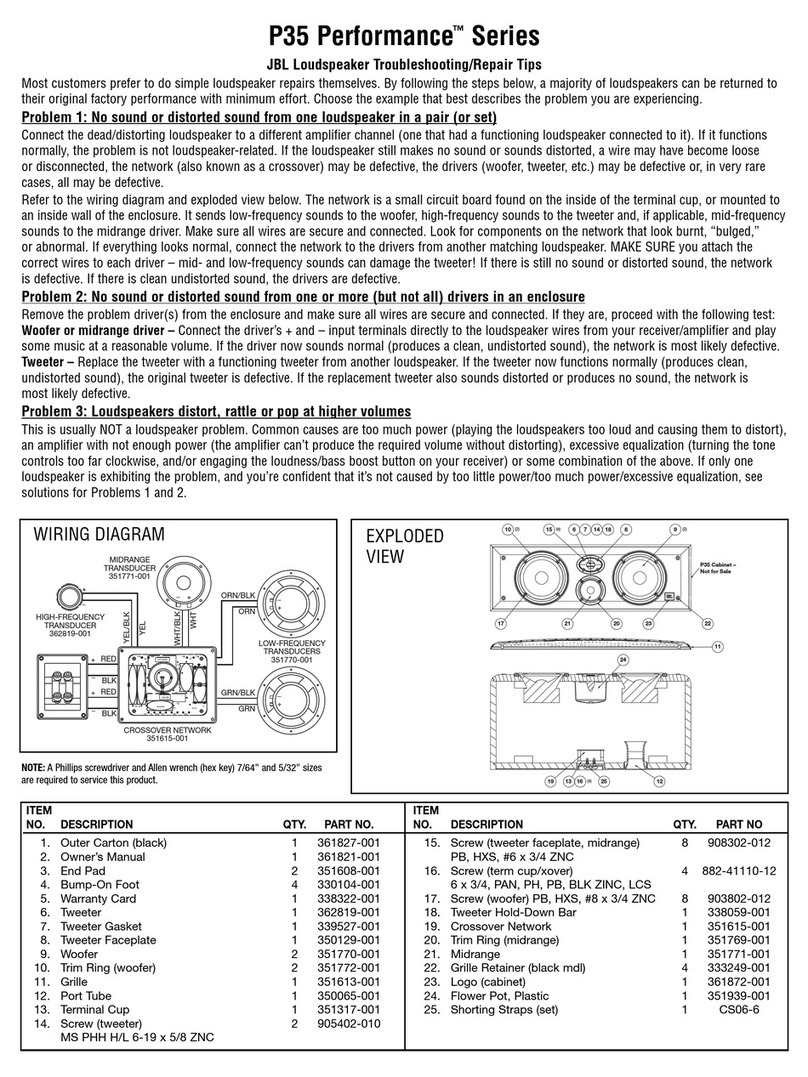

Guide to Connection Pins on Control 226C/T -- There

are two (2) removable locking input connectors with two (2)

terminals on each. The pin functions are listed on the label

located on the cover on the rear of the can.

On the Control 226C/T, connect the negative wire to the “-”

or pin 2 and connect the positive wire to “+” or pin 1. Pins 1

& 2 are looped to pins A & B, respectively (Pin 1 connects

to Pin A and Pin 2 connects to Pin B) inside the speaker.

Pins A & B are intended as loop-through connections to

subsequent loudspeakers. (See next page Using Loop-

Through Terminals).

To select the operating mode or desired output tap of the

loudspeaker, simply rotate the tap selector switch located on

the front of the baffle to the desired setting.

Note: Both 70V/(100V) connections and low impedance

connections are made at the same pins. When using the

transformer tap selections, be sure that the power amplifier

is set on 70V/(100V) Mode and the leads feeding the system

are connected to 70V/(100V) outputs on the amplifier.

Control 227C & Control 227CT

Guide to Connection Pins on Control 227CT -- The

removable locking input connector contains 5 terminals, as

marked on the connector. The pin functions are listed on the

label located on the crossover frame.

WIRING INSTRUCTIONS

AD

C

BE

INPUT CONNECTION FROM

70V/100V AMPLIFIER LINE

Com 30W15W

7.5W 60W

70V

Com

60W

30W15W

N/C

100V

BLACK

ORANGE

PURPLE

BLUE

WHITE

Control 227CT:

CONNECTION

+

IN

1 2

-

IN

Control 226C/T

+

A

-

Loop

Thru

B

Loop

Thru

Control 226C/T:

Control 226C/T

Terminal Shown