Maintenance

Important safety instructions for installation

Disconnect the power supply whenever you proceed to the installation or repair

of the control panel.

•The panel must be installed while the power is disconnected.

•Before installing the panel, remove all unnecessary ropes or chains and disable any equipment such as

locks that is not necessary for the automatic operation.

•Before installing the panel, check that the door is in good mechanical condition, correctly balanced and

that it opens and closes correctly.

•Install the manual unlocking device at a height lower than 1.8m.

•Install any permanent control next to the door away from any moving part and at a minimum height of

1.5m.

•For permanently connected equipment, an easily accessible power disconnection device must be incor-

porated into the wiring. It is recommended that this be of the emergency switch type.

•If the control panel is supplied without emergency stop button, this will be incorporated in the installation,

connecting it to the STOP terminal.

•For correct use of the security edge, this must never be activated when the door is fully closed. It is wise to

install the ends of run before activating the edge.

•This equipment can only be handled by a specialist fitter, by maintenance staff or by a suitably trained

operator.

•To connect the power supply and motor wiring, 2.5 mm2 section terminals must be used.

•Use protective goggles when handling the equipment.

•Fuses must only be handled when the appliance is disconnected from the mains.

•The instructions for using this equipment must remain in the possession of the user.

•European door normative EN 12453 and EN 12445 specify the following minimum protection and

door safety levels:

- for single-family dwellings, prevent the door from making contact with any object or limit the force of con-

tact (e.g. safety band), and in the case of automatic closing, it is necessary to complement this with a pres-

ence detector (e.g. photocell).

- for communal and public installations, prevent the door from making contact with any object or limit the

force of contact (e.g. safety band), and complement this with a presence detector (e.g. Photocell).

Important safety instructions for use

•Do not allow children to play with the door controls.

•Keep the remote controls out of the reach of children.

•Watch the door movement and keep people away until the door is fully open or closed.

•Precaution when operating the manual unlocking device, as the door may suddenly fall due to the bad

condition of the springs or door unbalance. Details on how to use the manual unlocking device must be

provided by the manufacturer or the device installer.

•Examine the installation frequently, especially the cables, springs and supports, to detect signs of wear,

damage or unbalance. Do not use the door if repair work or adjustments are required, as this may cause

damage.

Use of the equipment

Designed for automation of garage doors, in accordance with the general description. Not guaranteed for other uses. The man-

ufacturer reserves the right to alter equipment specifications without prior notification.

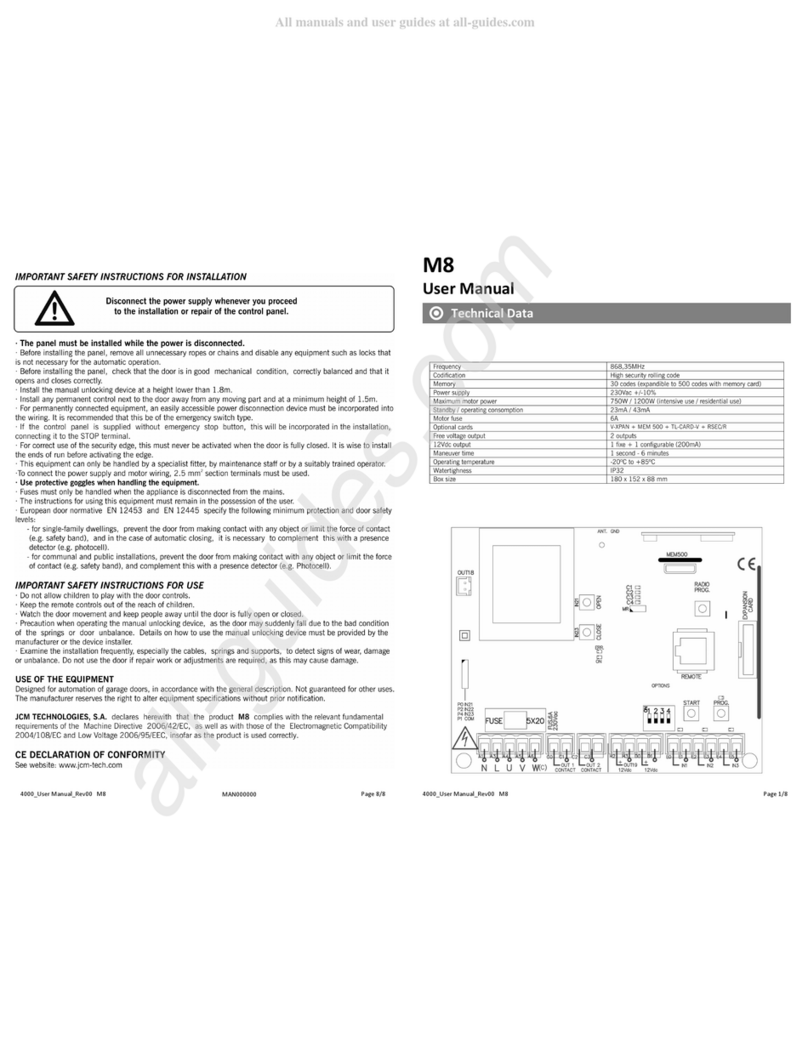

jcmtechnologies

2