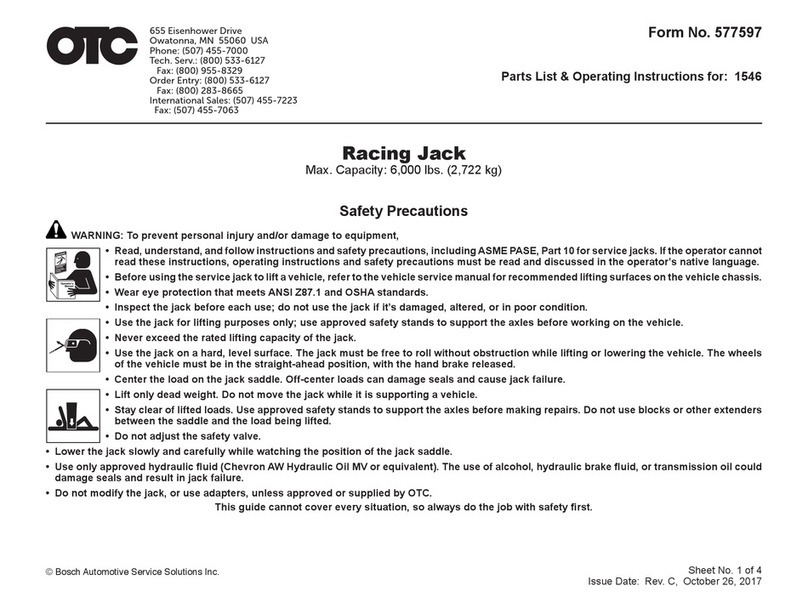

Safety Precautions

CAUTION: To prevent personal injury and damage to equipment,

•Study, understand, and follow all instructions before using this device. If the operator

cannot read these instructions, operating instructions and safety precautions must be

read and discussed in the operator’s native language.

•Before using the service jack to lift a vehicle, refer to the vehicle service manual to

determine recommended lifting surfaces on the vehicle chassis.

•Wear eye protection that meets ANSI Z87.1 and OSHA standards.

•Inspect the jack before each use; do not use the jack if it’s damaged, altered, or in poor

condition. Take corrective action if any of the following conditions are found: cracked or

damaged housing; excessive wear, bending, or other damage; leaking hydraulic uid;

scored or damaged piston rod; loose hardware; modied or altered equipment.

•A load must never exceed the rated lifting capacity of the jack.

•Use the jack on a hard, level surface. The jack must be free to roll without any obstructions

while lifting or lowering the vehicle. The wheels of the vehicle must be in the straight-

ahead position, and the hand brake released.

•Use the jack for lifting purposes only. Stay clear of a lifted load. Place support stands under the

axles before working on the vehicle.

•Center the load on the jack saddle. Off-center loads can damage seals and cause jack failure. Lift

only dead weight.

•Do not use blocks or other extenders between the saddle and the load being lifted.

•Do not modify the jack or use adapters unless approved or supplied by OTC.

•Lower the jack slowly and carefully while watching the position of the jack saddle.

• Use only approved hydraulic uid (Chevron AW Hydraulic Oil or equivalent). The use of alcohol,

hydraulic brake uid, or transmission oil could damage seals and result in jack failure.

This guide cannot cover every situation, so always do the job with safety rst.

Parts List & Operating Instructions Form No. 522982, sheet 2 of 3, back

Setup

Assembling the Handle

1. Loosen the thumb screw on the back of the handle socket.

2. Grease the socket opening. Insert the handle.

3. Torque the thumb screw again to 150–200 in. lbs.

Bleeding Air from the Service Jack

Air can accumulate within a hydraulic system during shipment or after prolonged use. This entrapped air

causes the jack to respond slowly or feel “spongy.” To remove the air:

1. Open the release valve by turning the handle all the way counterclockwise (CCW).

2. Pump the handle six full strokes.

3. Close the release valve by turning the handle all the way clockwise (CW).

4. Pump the handle until the lift arm is fully extended.

5. Lower the lift arm by turning the handle all the way counterclockwise (CCW). If the jack does not

immediately respond, repeat steps 2–4.