JENTNER Picco+ User manual

Pin electroplating device Picco+

1. General information

1. Carefully unpack the device. Watch for damage. Damages must be reported to the supplier

immediately.

2. Read the user manual thoroughly and carefully. The operator shall ensure that each user

of the appliance has read the instructions carefully before putting it into service.

3. Keep the instructions in a place accessible to all users.

2. Commissioning of the device

The device has been tested by us for its perfect function and has been carefully packaged.

Please unpack the device carefully. Set it up at working height. Plug the power plug of the

device into the wall outlet.

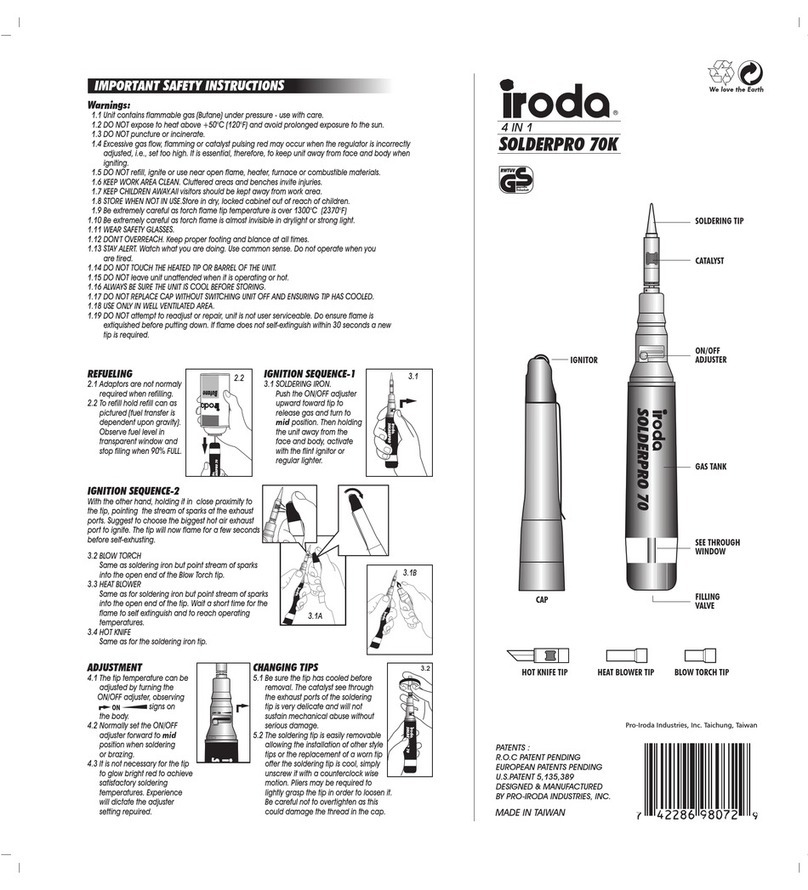

Construction of the device:

Rectifiers

Electrode pin with cable

Cable with goods terminal

1. Connect the plug of the electrode pin (red) to the red socket of the device.

2. Connect the cathode cable plug (black) to the black socket of the device.

Note: Only the amount of electrolyte needed for the electroplating process should be used.

3. Preparation and procedure

3.1 Cleaning of the goods

• The product to be galvanized must be cleaned well, the following procedure is recommended:

-Ultrasonic cleaning

-Electrolytic degreasing

-Drying

Note: Rinse thoroughly after each cycle. We recommend ultrasonic cleaning and electrolytic

degreasing. After cleaning, the product is dried without stains. It can now be covered with a

cover pen, for example, or glued with adhesive film.

Attention: It is essential to make sure that the surfaces to be coated (galvanized) must no

longer be touched with the hands or other skin parts, possibly wear gloves.

3.2 Electroplating

• For galvanizing, the workpiece to be machined is contacted with the product clamp.

• Set the voltage regulator to the appropriate voltage (LED).

•Draw electrolyte from the electrolyte container with the felt of the electrode pin.

• For electroplating, slide the electrode pin evenly over the surface of the workpiece several

times, whereby betweenthe surface of the goods and the felt of the electrode pin there should

be a thin electrolyte film.

• After galvanizing, rinse the product immediately in water to prevent staining and to avoid

chemical attack. Then remove the cover surface or adhesive film and degrease again, if

necessary. Then rinse and dry again.

• Leave the felt in the pen (replace the soiled felt) and thoroughly soak again with the same

electrolytes during a new process.

Attention: The electrolytes must not be mixed. Different felts should be used for different

electrolytes, as the electrolytes may become unusable due to carryover. In order not to

contaminate the electrolyte in the reservoir, used electrolyte should not be returned to the

original bottle.

4. Sources of error

4.1 The goods accept electrolyte only partially:

•The product is stained or oxidized

- Degrease the product thoroughly (see Chapter 3.1)

- The felt must be completely soaked with electrolyte.

•The felt is dirty.

- Change felt.

4.2 No deposit takes place

•There is no contact between the rectifier and the product.

- Check the contact from the rectifier to the product terminal

(black socket - cathode cable - terminal - commodity)

•The goods are protected against tarnishing.

- Remove the varnish.

•The power cord has not been plugged in or the device is not switched on.

- Check that the power cord is plugged into the power outlet.

- Check that the device is switched on.

•The fuse is defective.

- The device must be checked and repaired by an authorized technician

4.3 The deposition is faulty

•The electrolyte is contaminated.

- Replace the electrolyte, but first fill the electrolyte tank with distilled water clean

thoroughly with water.

•The voltage (volts) has been set incorrectly

- The respective voltage specification can be found in the product description of the

pen bath

•It was electroplated too long on the same spot without absorbing new electrolyte

- Pick up electrolyte with the felt and pass it evenly over the fabric

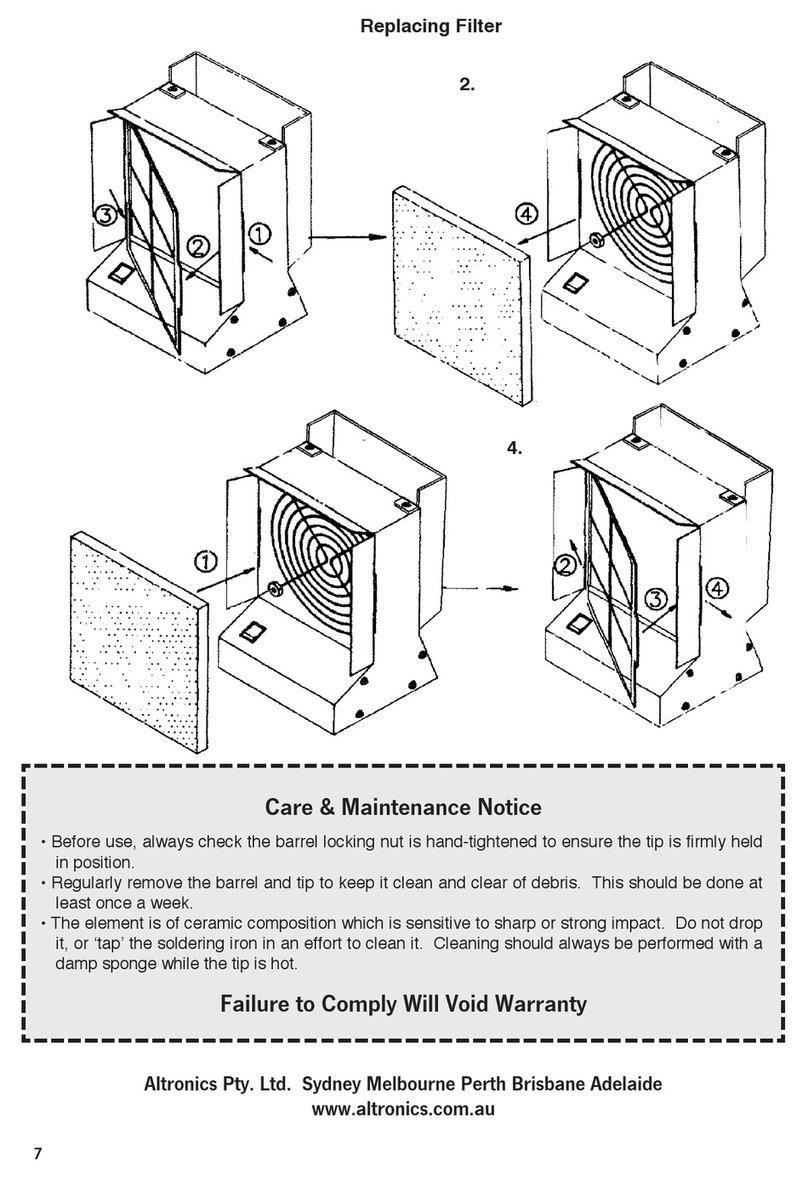

5. Cleaning instructions

The Picco+ is maintenance-free. Every now and then, the plating pins should be cleaned and

the felts replaced. To clean the pen, remove the tip,rinse the front part of the pen well with

normal water and rinse with distilled water. A new tip is then inserted. Parts that have already

been degreased should never be stored unprocessed for a longer period of time in order to

avoid staining and oxidation.

6. Safety instructions

When using electrical equipment, observe the following basic safety precautions to protect

against electric shock, injury, and fire. Read and observe these instructions before using the

device!

6.1 Keep your work area in order!

6.2 Take environmental influences into account!

6.3 Keep children away!

6.4 Check your device for damage!

6.5 Do not misuse the power cord!

6.6 Care for the device with care!

6.7 Only use the correct accessories!

7. Technical data

Housing: painted high quality steel

Dimensions (WxDxH): 120 x 150 x 95 mm

Rectifier: 12V/ 1.5A

Supply voltage: 230V/ 50Hz

Equipment: 1 pin (anode)

1 terminal (cathode)

5 felts

If you need assistance withthe commissioning of the device, please contact us. You canreach

your request.

For more information, click here:

Jentner Plating Technology GmbH

Johann-Staib-Strasse 2

75179 Pforzheim - Germany

Tel.: +497231 - 41 80 94-0

E-mail: sales@jentner.de

Store: www.shop.jentner.de/en

Table of contents