small sponge

large sponge

CAUTION

Using the sponge without water may damage the

tips.

2014.5

MA02600XZ140512

Soldering Station

Instruction Manual

Thank you for purchasing the HAKKO FX-100 Soldering Station.

Please read this manual before operating the HAKKO FX-100.

Keep this manual readily accessible for reference.

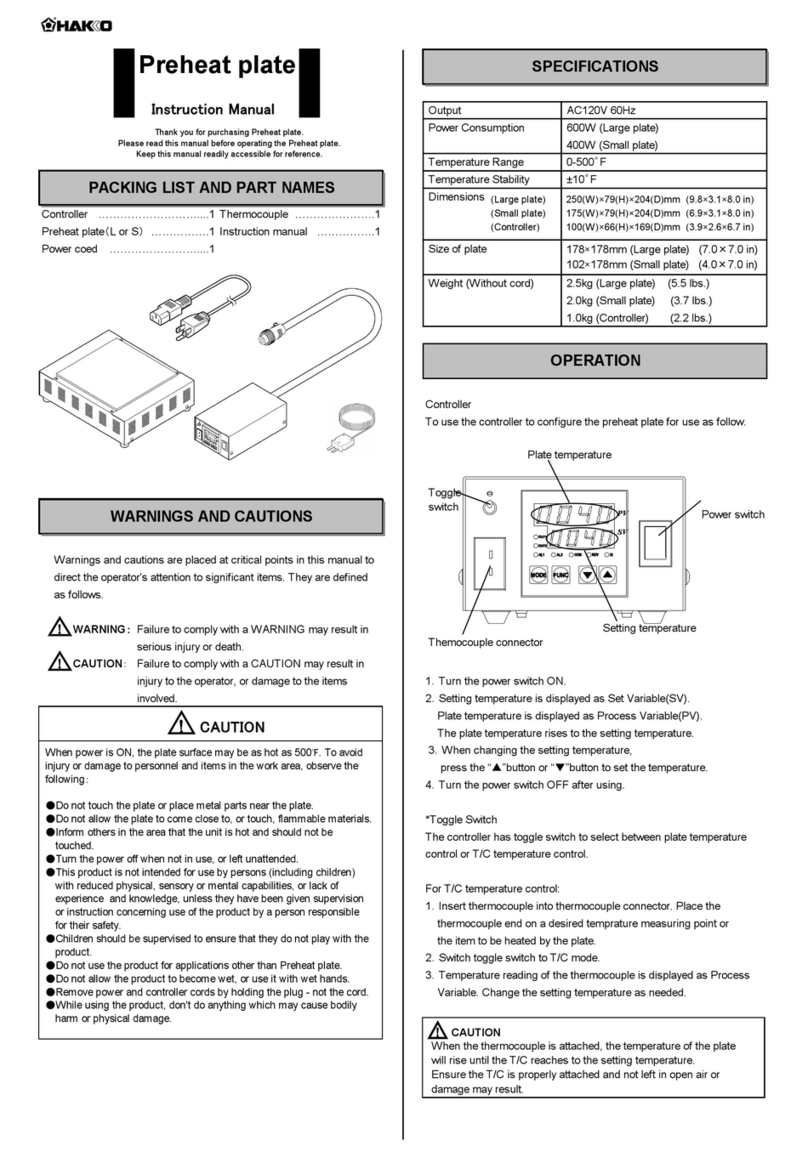

1. PACKING LIST AND PART NAMES

HAKKO FX-100 soldering station 1

HAKKO FX-1001 soldering iron 1

Sleeve (Green) 1

Sleeve (Gray) 1

Cleaning wire 1

Heat resistant pad 1

Iron holder 1

Power cord 1

Instruction manual 1

Please check to make sure that all items listed

below are included in the package.

CAUTION

This product includes such features as electrically conductive plastic parts and grounding of the handpiece

and station as measures to protect the device to be soldered from the effects of static electricity. Be sure to

observe the following instructions:

1. The handle and other plastic parts are not insulators, they are conductors. When replacing parts or

repairing, take sufficient care not to expose live electrical parts or damage insulation materials.

2. Be sure to ground the unit during use.

* Specifications and design are subject to change without notice.

4. INITIAL SETUP

A. Iron holder

This product includes two methods for cleaning the

tip: a wire tip cleaner, and a sponge. Please be

sure to soak the sponge in water before using.

1. Set the iron holder.

2. Put the small cleaning sponge in one of the five

holes in the iron holder base.

3. Add water to the iron holder base. The small

sponge will keep the large sponge moist through

capillary action.

4. Wet the large sponge, squeeze it dry and put it

on the iron holder base.

B. Handpiece cord assembly

1. Pass the iron cord through the hole in the heat

resistant pad.

2.HoldtheheadpartoftheT31seriestip(not

included)withtheheatresistantpadandinsert

thetipintothehandpiece.Pushuntilthetip

stops.

C.Station

1. Insert the power cord into the receptacle at the

back of the station.

2. Insert the connection cable plug into the

receptacle at the front of the station, and turn it

in a clockwise direction until it stops.

3. Set the iron in the iron holder.

4. Plug the power cord into a grounded wall socket.

CAUTION

Be sure the power switch is OFF before connecting or disconnecting the soldering iron cord. Failure to do so may

result in damage to the circuit board.

CAUTION

The HAKKO FX-100 is protected against electrostatic

discharge and must be grounded for full efficiency.

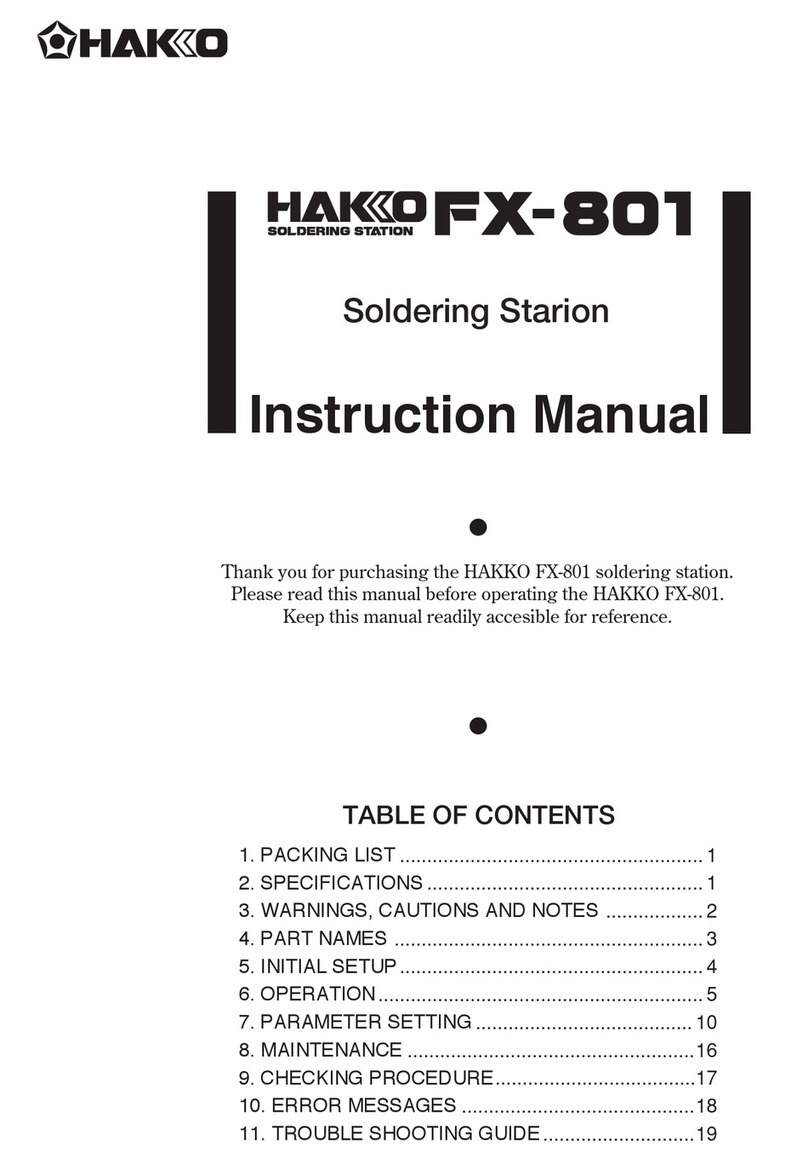

HAKKO FX-100

Soldering station

HAKKO FX-1001

Soldering iron

Power cord

Heat resistant

pad

Iron holder

Iron holder

base

Cleaning

sponge

Sleeve

(Green)

Sleeve

(Gray)

Power switch

Receptacle

2. SPECIFICATIONS

Output power

Output frequency

Dimensions

Weight

50 W

13.56 MHz

127 (W) × 150 (H) × 167 (D) mm

(5.0 × 5.9 × 6.6 in.)

3 kg (6.6 lb.)

Station

HAKKO FX-1001 soldering iron

Length of cord

Total Length (w/o cord)

Weight (w/o cord)

1.3 m (4.3 ft.)

190 mm (7.5 in.) with T31-02D24 tip

31 g (0.07 lb.) with T31-02D24 tip

NOTE:

This product is protected against electrostatic discharge.

28 W (85 W)

T31-01 Series / 450℃(840℉)

T31-02 Series / 400℃ (750℉)

±1.1℃(±2.0℉)

Power consumption

Tip series /

Tip temperature

Temperature stability

Copyright © 2014 HAKKO Corporation. All Rights Reserved.

OVERSEAS AFFILIATES

U.S.A.: AMERICAN HAKKO PRODUCTS, INC.

TEL: (661) 294-0090 FAX: (661) 294-0096

Toll Free (800)88-HAKKO

4 2 5 5 6

http://www.hakkousa.com

HONG KONG: HAKKO DEVELOPMENT CO., LTD.

TEL: 2811-5588 FAX: 2590-0217

http://www.hakko.com.hk

SINGAPORE: HAKKO PRODUCTS PTE LTD.

TEL: 6748-2277 FAX: 6744-0033

http://www.hakko.com.sg

Please access to the following address for the other Sales affiliates.

http://www.hakko.com

HEAD OFFICE

4-5, Shiokusa 2-chome, Naniwa-ku, Osaka 556-0024 JAPAN

TEL:+81-6-6561-3225 FAX:+81-6-6561-8466

CAUTION

WARNING

To prevent accidents or damage to the HAKKO FX-100, be sure to observe the following:

When power is ON, the tip will be hot. To avoid injury or damage to personnel and

items in the work area, observe the following:

Do not touch the tip or the metal parts near the tip.

Do not allow the tip to come close to, or touch, flammable materials.

Inform others in the area that the unit is hot and should not be touched.

Turn the power off when not in use, or left unattended.

Turn the power off when changing parts or storing the HAKKO FX-100.

The unit is for a counter or workbench use only.

This appliance can be used by children aged from 8 years

and above and persons with reduced physical, sensory or

mental capabilities or lack of experience and knowledge if

they have been given supervision or instruction concerning

use of the appliance in safe way and understand the hazards

involved.

Children shall not play with the appliance.

Cleaning and user maintenance shall not be made by

children without supervision.

Do not use the HAKKO FX-100 for applications other than soldering.

Do not allow the HAKKO FX-100 to become wet, or use it when hands are wet.

Do not modify the HAKKO FX-100.

Use only genuine HAKKO replacement parts.

Be sure to hold the plug when inserting or removing the iron cord.

Do not strike the iron against hard objects to remove excess solder. This will damage

the iron.

Be sure the work area is well ventilated. Soldering produces smoke.

While using the HAKKO FX-100, don't do anything which may cause bodily harm or

physical damage.

3. WARNINGS, CAUTIONS AND NOTES

Warnings, cautions and notes are placed at critical points in this manual to direct the operator’s

attention to significant items. They are defined as follows:

CAUTION : Failure to comply with a CAUTION may result in injury to the operator, or damage to the

items involved. Two examples are given below.

WARNING: Failure to comply with a WARNING may result in serious injury or death.

NOTE : A NOTE indicates a procedure or point that is important to the process being described.

Cleaning wire

*When using a Cleaning Wire

Place it in the iron holder as shown on the right. See "2.Using a Cleaning Wire"

in section "7. MAINTENANCE"