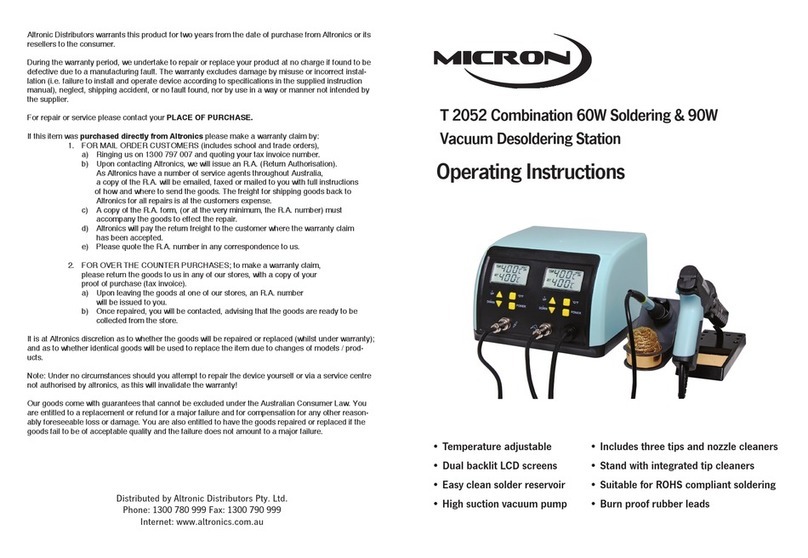

Micron T 2444A Soldering Station

Congratulations on purchasing the Micron T 2444A Temperature Controlled

Soldering Station with Fume Extractor. Its compact size ensures that the work surface

is not cluttered up and it is easily positioned to ensure maximum effect.

Product Description:

This specialised soldering station has been developed to meet the present and

future needs of the electronic production industry. The all metal construction

coupled with the high performance ball bearing fan makes this ideally suited to

production line assembly, service centres, work benches, colleges etc.

It incorporates electronic circuitry which enables the user to change the tip

temperature from 250°C through 450°C without changing the tip or heating element.

The transformer-less power supply ensures excellent temperature stability by

accurately monitoring the minute changes in element resistance which occur in

proportion to temperature variations.

The electronic opto isolated “zero voltage” switching used protects voltage and

current sensitive components, such as CMOS devices, against transient voltage

spikes, which can be caused by switching the power or heater on/off, or other

environmental conditions.

The ceramic heating element is designed specially to bring the element

temperature up to approximately 450°C at full setting in under one minute. The

higher temperature allows for reserve heat to ensure ultrafast recovery at lower

temperature settings.

The high insulation of the ceramic heating element is over 100Mohm and the tip is

grounded to ensure leakage is less than 0.4 millivolts.

Inside the box:

• T 2444A • AC Power Cord • Instruction Manual • Soldering Handle Stand

Specifications:

Input Power: ..................................................................................................... 220-240VAC

Solder Station Wattage: ................................................................................................. 60W

Temperature Range: ........................................................................................ 250 - 450°C

Tip Leakage: .............................................................................................................. < 2mV

Tip To Ground Resistance: .................................................................................... < 0.1ohm

Stability @ Idle: ............................................................................................................ ±5°C

Fan Wattage: ................................................................................................................ 20W

Maximum Air Volume: ...................................................................................... 95/115 CFM

Outer Dimensions: ...................................................................... 162W X 200H X 120D mm

Weight (Excluding AC Cord): ............................................................................... 1500grams

Replacement Filter (130mm2): .................................................................................. T 1291

1