General Safety Information

Always wear safety glasses when using a grease gun. Keep work

area clean and remove any excess grease from tools, hands, and

clothing after use. Do not use grease gun whip hose for other

applications or at pressure levels above rated pressures.

WARNING - HIGH PRESSURE GREASE

NEVER allow contact of the output of the Grease Gun (coupler)

to a person's skin or body, injection of grease under the skin

could occur causing serious illness or death.

CAUTION

If left on floors, tools, or equipment, excess grease can cause

surfaces to become slippery.

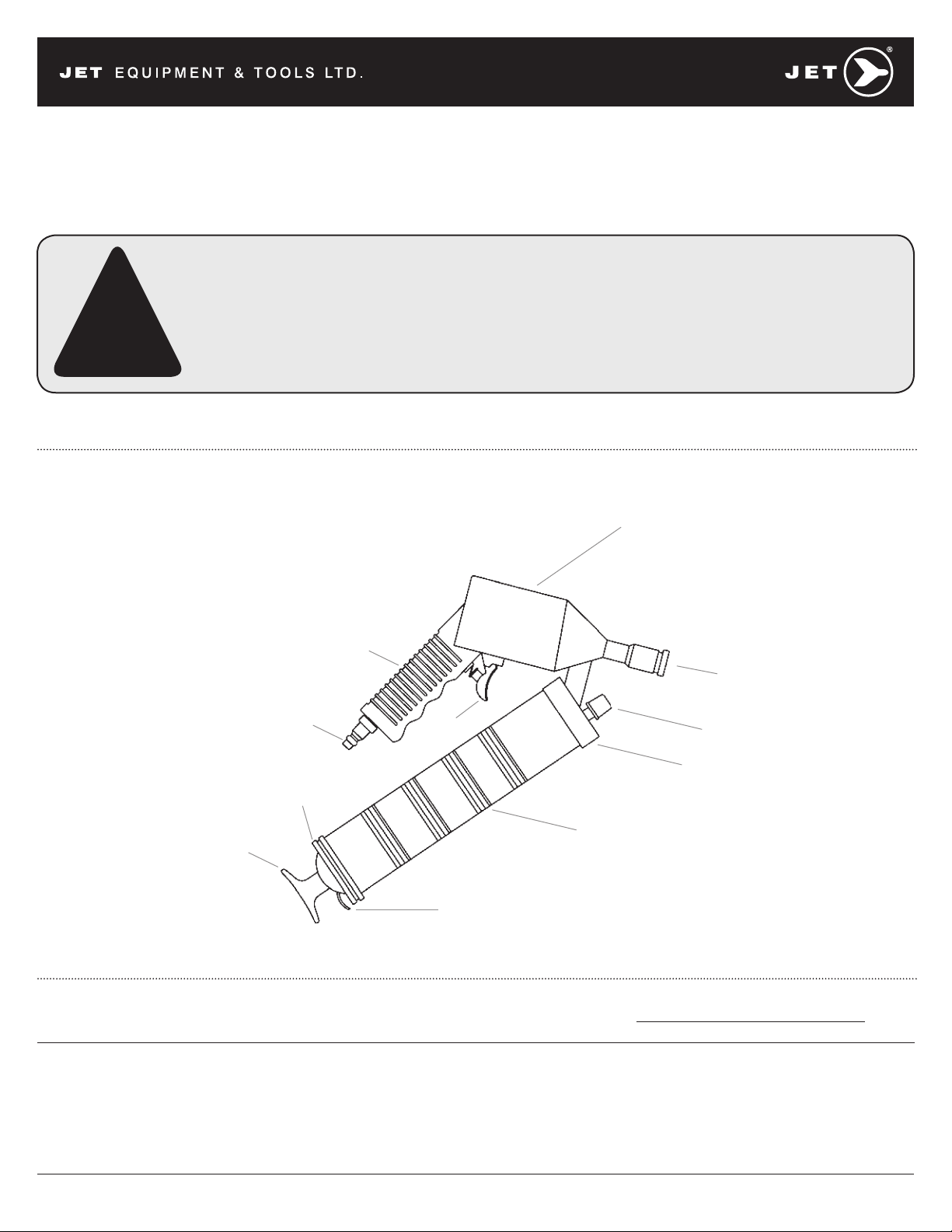

Getting Ready to Use the Air Powered Grease Gun:

Air supply: You need dry air to operate this gun. Make sure an FRL

(Filter, Regulator, and Lubricator) unit is installed on your airline.

Moisture in the air will damage the grease gun. The compressor

you use must have a minimum volume of 1 CFM (0.026 cubic

meter). Inlet air supply should have a pressure between 40-120 PSI

(3–8 BAR). The recommended working pressure is 90 PSI (6 BAR).

This grease gun has a 40:1 pressure ratio; i.e. the grease discharge

pressure will be 40 times the inlet air pressure.

Lubrication: Like all air equipment, this grease gun needs regular

lubrication. To lubricate, add a few drops of oil through the air inlet

on the grease gun. It is recommended to use SAE 30 or greater oil.

Connecting the grease gun to air supply: There are several types

of quick connect couplers available in the market. This grease gun

comes with one standard male quick connect coupler. The coupler

must fit properly onto the female quick connect coupler on your

airline. If it does not fit properly, use a coupler that does.

Operating the grease gun trigger: This is a continuous action

grease gun, whereby there is continuous grease discharge with the

trigger pressed. Care must be taken not to over-lubricate due to

continuous action. Grease gun is capable of dispensing a full

14 oz. (400 gms) grease cartridge in 1 minute.

Setting Up the Grease Gun Head:

Attach the male quick connect coupler air fitting onto the air inlet on

the die cast handle. The male quick connect coupler air fitting has

1/4" NPT threads and should be threaded into the female hole on

the die cast handle using thread sealant. The connection should

be tight.

CAUTION

Grease or empty cartridge in barrel is under pressure from the

internal spring, use caution when removing either end of

the barrel.

Do not apply excessive torque or over-tighten the air fitting

as this will apply undue stress to the die cast outlet and may

cause it to fracture.

Preparing to Load Your Grease Gun:

1. Make sure the gun is disconnected from the air supply. Remove

any cartridge in the grease gun barrel prior to refilling. To check if

a cartridge is in the barrel first compress the spring by pulling the

plunger handle out to its maximum distance and lock it in place.

2. Remove the grease gun head by turning it counter clockwise.

3. Remove any empty cartridge.

There are 3 ways to load your grease gun: cartridge, bulk,

or filler pump. Always follow the steps listed above when

preparing to load your grease gun before proceeding to the

appropriate loading method.

Loading Grease Gun Cartridges:

1. Make sure the gun is disconnected from the air supply. Loosen

but do not remove the grease gun head from the grease gun

barrel by turning the grease gun head in a counter clockwise

direction 1-1/2 turns. Pull back and lock the plunger handle all

the way to the end of the barrel so the grease cartridge can

be fully inserted.

2. Now rotate the grease gun head in a counter clockwise direction

to unscrew the grease gun head from the barrel completely.

3. Remove the plastic cap from the grease cartridge and insert the

open end of the cartridge into the grease gun barrel until the rim

of the pull-tab end meets the rim of the grease gun barrel.

Now remove the pull-tab seal.

4. Screw the head of the gun onto the barrel, but do not fully

tighten the barrel. For now leave at least 2-3 turns before the

barrel is fully tightened against the gasket in the head.

5. Unlock the plunger rod handle from the end cap.

6. Move the plunger rod forward and backward to force out any

trapped air pockets from the grease. Air will escape from the

connection between the grease gun head and the barrel,

which is not fully tightened.

7. Reconnect the air supply and “prime” the system by pressing

the trigger until the grease starts coming out of the discharge

nozzle. Initial grease discharge may have trapped air. Once the

gun has been primed, fully tighten the grease gun head onto

the barrel.

8. Push the plunger rod into the barrel for easier manoeuvrability

during use.

9. You should now connect the grease gun extension and coupler

onto the grease gun outlet. The connection between the

extension and grease gun must be tight and it is advisable to

use a thread sealant to ensure a leak-proof joint.

www.jetequipment.com