4

Specifications: HB-1648H HB-2248H

Stock Number...........................................................756216......................................................... 756222

Capacity...................................................................16 Gauge x 48” Wide .............22” Gauge x 48” Wide

Overall Dimensions (LxWxH)....................................61”x21”x28”............................................61”x21”x26”

Maximum Lift of Beam..............................................1-1/4”.................................................................7/8”

Beam Adjustment (front to rear)................................5/8”....................................................................1/8”

Uncrating and Clean-Up

1. Remove the crate from around the machine.

2. Carefully clean all rust protected surfaces

with a mild solvent or kerosene and a soft

rag. Do not use lacquer thinner, paint

thinner, or gasoline. These will damage

painted surfaces.

3. Coat all machined surfaces with a light coat

of oil to inhibit rust.

4. Remove the bolts holding the machine to the

skid.

5. Carefully move the machine to a well lighted

area on a solid, level work bench, and

secure to the bench with lag screws or bolts.

6. Machine location must allow access to all

sides.

Brake Setup

The brake will not bend properly if it is not level.

Use a machinist’s level and shims if necessary.

Apron Adjustments

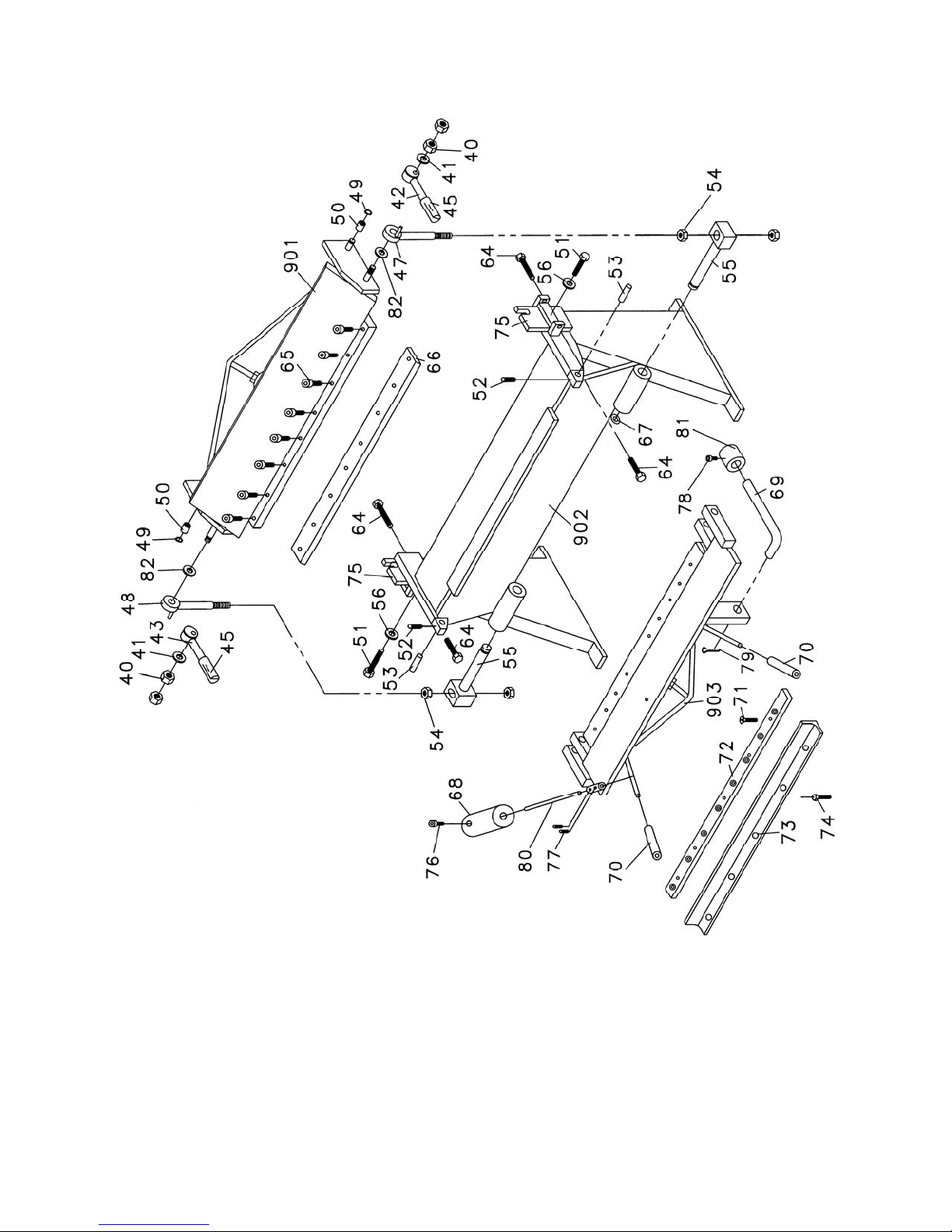

The (#) in the text refers to the breakdown.

The apron assembly has been adjusted at the

factory for proper use of capacity material.

During shipment of this unit the machine may

have come out of alignment.

The forward edge of the holddown (66) should

be adjusted parallel to the pivot edge of the

clamp block. Release clamping pressure on the

holddown assembly by pushing clamp handles

slightly to the rear. Turn the hex cap screws (64)

to adjust for parallel.

The center of the apron can be adjusted by

tightening the truss nut on the apron assembly.

Operating the Brake

Adjusting for Metal Thickness:

The hold-down assembly must be adjusted to

allow for clearance when making bends

according to the thickness of the material.

Clearance for material within four gauges of the

capacity should be twice the thickness of the

material. For lighter gauges use 1-1/2” times the

thickness. The forward edge of the hold-down

(66) should be adjusted parallel to the pivot

edge of the clamp block. Release clamping

pressure on the hold-down assembly by pushing

clamp handles (42 & 43) slightly to the rear.

Turn the hex cap screws (64) to adjust for

parallel and proper clearance. The center of the

hold-down can be adjusted by tightening the

truss nut on the hold-down assembly.

Adjusting the Clamping Pressure:

The clamping pressure should be adjusted

according to the thickness of the material. The

clamping pressure should be great enough to

hold the material securely in place but not so

much that it is difficult to lock the clamping

handles. Clamping pressure can be adjusted by

turning the lower nuts (54) on the threaded rod

portion of the yoke assembly (48).

Flange Capacity:

The recommended minimum flange in capacity

material is one inch.

Repeat Bends:

Adjust the stop (81) on the stop rod (69) to limit

the swing of the apron assembly.

Counter Weight:

The counter weight (68) can be moved up or

down to provide more or less leverage

depending on the material.

Lubrication

The machine must be lubricated every day of

service with a few drops of oil. Oil pinholes are

located at both yoke assemblies (47 & 48), and

the apron assembly near the hinge pin (53).

Lightly oil the machined parts when not in use to

prevent rust.