JKS1610 JKS Control Arm Installation

2 Page

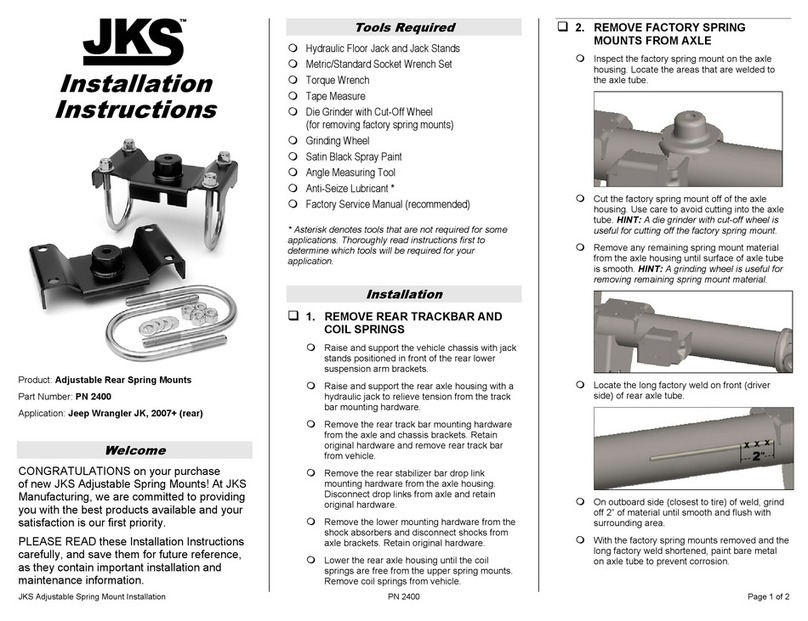

Remove the original lower suspension arm from

the vehicle.

Proceed to step 2. Complete installation on one

side before starting other side.

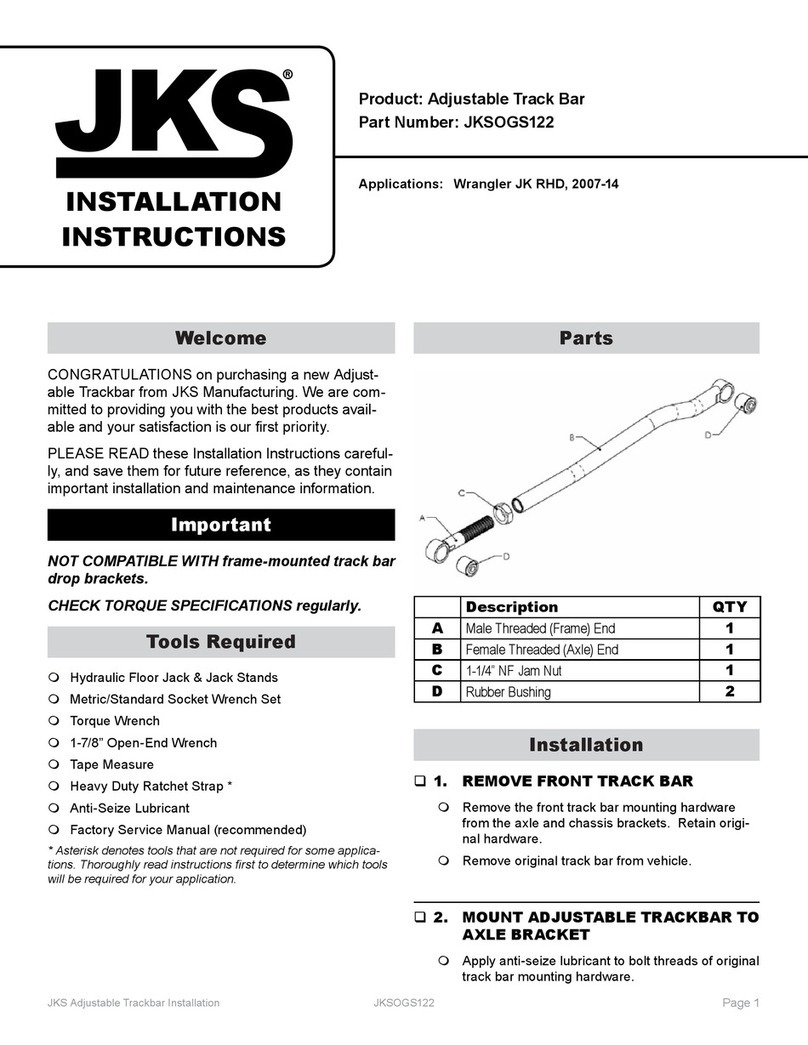

2. SET CONTROL ARM LENGTH

Determine the ideal arm length for your application

by considering factors such as:

ÂTire Clearance

ÂSteering Clearance

ÂPinion Angle / Caster

ÂFactory length is 22-5/8"

ÂMax. length is 24 3/8"

Set both control arms to the same length.

Lengthening the arms will increase caster and

reduce pinion angle.

3. INSTALL CONTROL ARM

Apply anti-seize lubricant to bolt threads of original

mounting hardware.

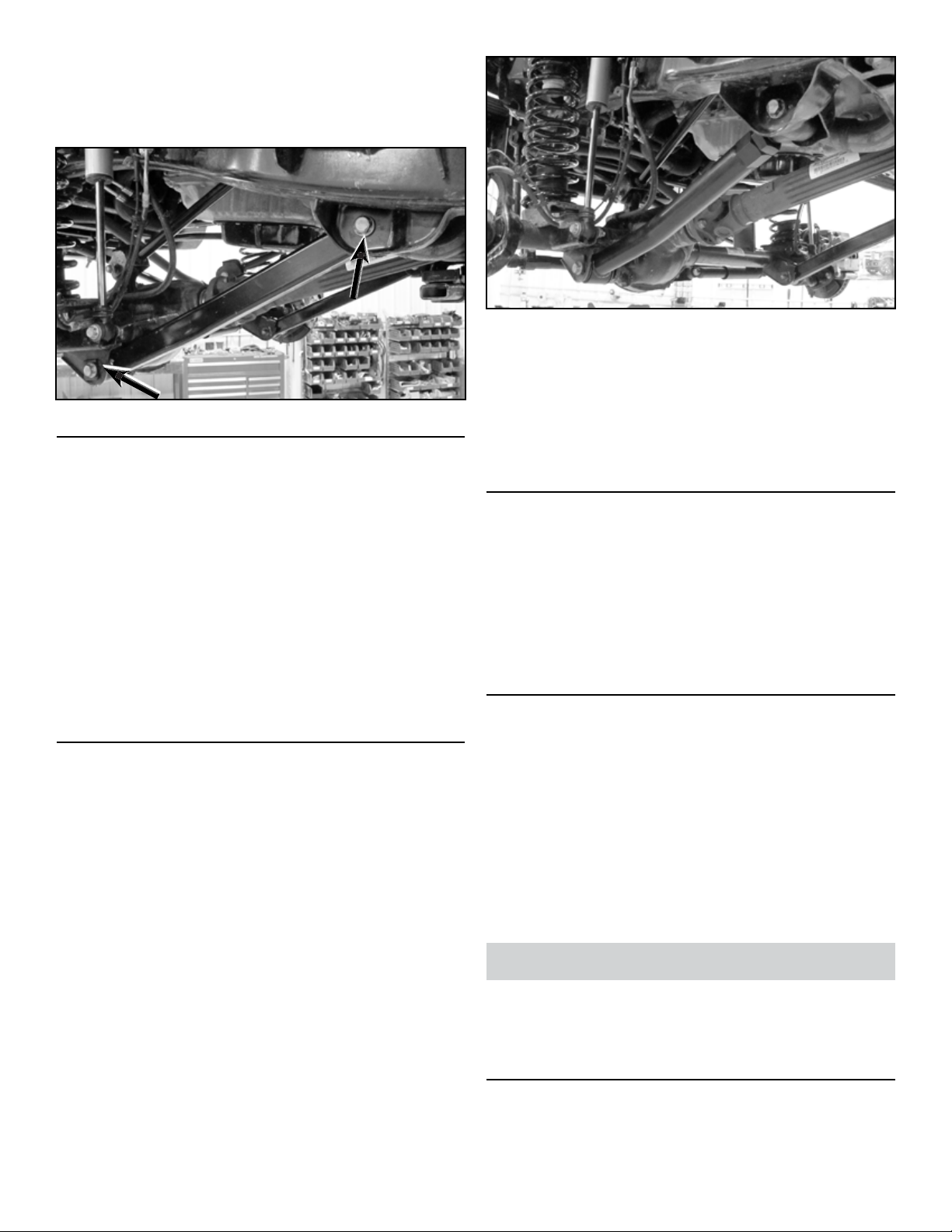

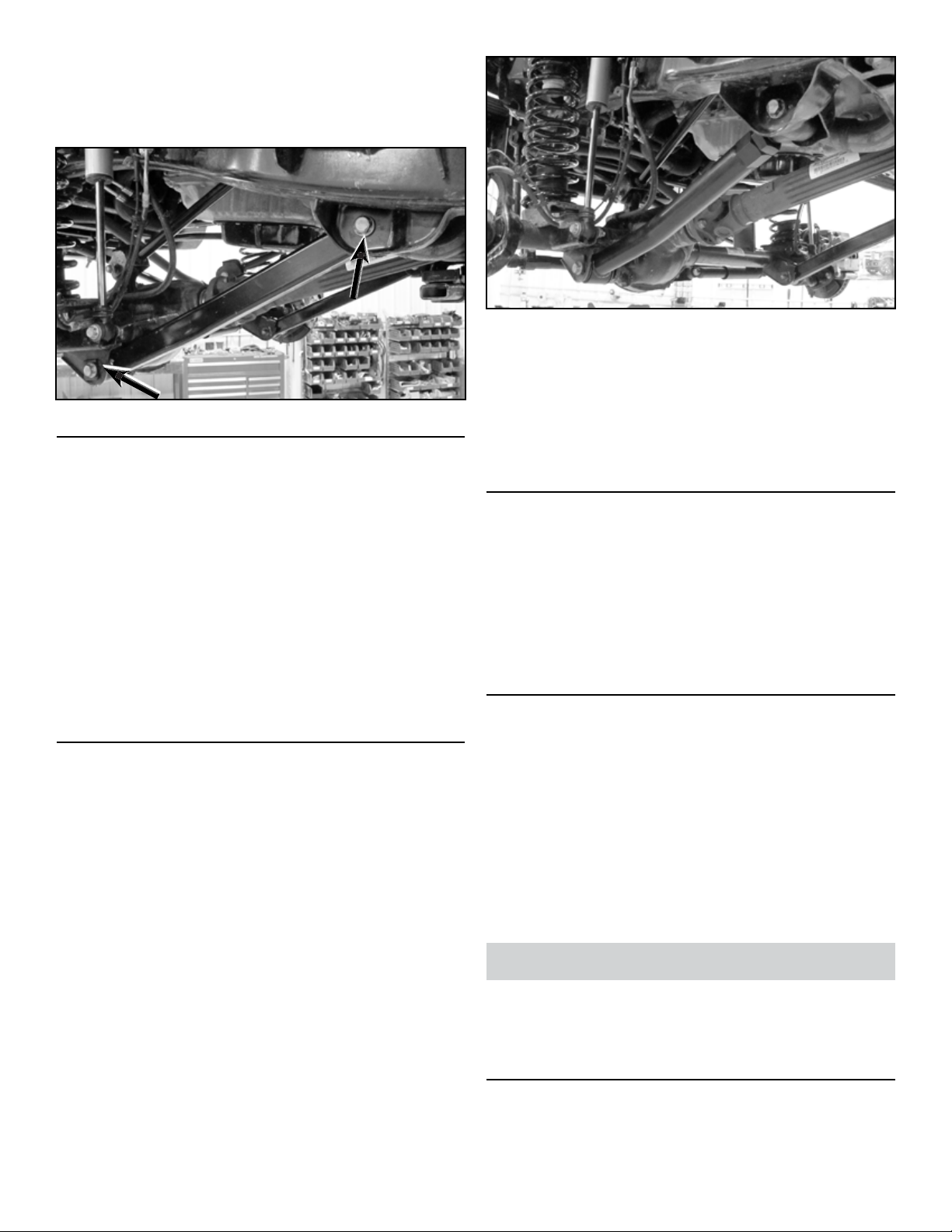

Establish control arm orientation. The arms

should be mounted so that the bend goes inward

(away from the tire) and the rubber bushing end

mounts to the axle.

Mount the control arm to the axle housing bracket.

Install the original mounting bolt and nger tighten

the nut. DO NOT torque mounting hardware until

instructed.

Mount the control arm to the frame rail bracket so

the grease tting is up on the ex eye. Install the

original mounting bolt and nut. Finger tighten the

bolt.

HINT: If mounting bolt is difcult to install due to misalign-

ment of Control Arm bushing with mounting bracket, either

(1) adjust height of axle housing with hydraulic jack, (2)

move axle housing into position with a heavy-duty ratchet

strap, or (3) temporarily disconnect track bar until mounting

holes align.

4. TIGHTEN MOUNTING HARDWARE

Once both control arms have been properly

installed, lower the vehicle to the ground until coil

springs are supporting the full weight of vehicle.

Using a torque wrench, tighten all mounting hard-

ware to 125 ft-lbs.

Tighten jam nuts using JKS1695 or equivalent.

5. POST-INSTALLATION INSTRUCTIONS

Installing longer lower control arms will affect the

vehicle alignment by adding more caster. This

may also slightly affect the steering wheel posi-

tion, making it off-center. It is important that the

steering wheel is centered to avoid adverse affects

on the vehicle's electronic stability control (ESC)

system. JKS recommends having the alignment

check by a qualied alignment shop.

Check mounting hardware for proper torque.

Check hardware after 500 miles of use.

Maintenance

Control arm ex ends should be greased regularly as part

of vehicle maintenance schedule or after every 4-wheeling

trip. Lubricate using marine grade grease. Rubber bush-

ings require no maintenance.

©2013 JKS Manufacturing, Inc & Aftermarketing, LLC

Revision Date 02/03/2014