JKSOGS960 /JKSOGS962 JKS Steering Brace System Installation

2 Page

ATTENTION INSTALLER

IMPORTANT NOTE REGARDING

DUAL STEERING BRACE SYSTEM

The following instructions refer to installation of a

single Steering Brace System (PN OGS960) on the

driver-side chassis rail only. For a dual Steering Brace

System (PN OGS962), the additional parts should be

installed on the passenger-side chassis rail using the

same procedures.

NOTE: Some vehicles are factory equipped with

steering gear mounting holes on both chassis rails.

Otherwise, it will be necessary to drill new holes on

the passenger-side chassis rail to accommodate the

supplied Support Sleeves.

Installation

1. PREPARE DRIVER-SIDE CHASSIS RAIL

ZThe following items must be removed from the

chassis rail, along with any other components that

prevent the Chassis Plates (A & B) from tting

ush against mounting surface. Refer to factory

service manual for specic instructions.

ÂTow Hook & Bracket

ÂLower Radiator Support Bracket

ÂFront Swaybar

ÂFront Bumper & Bracket

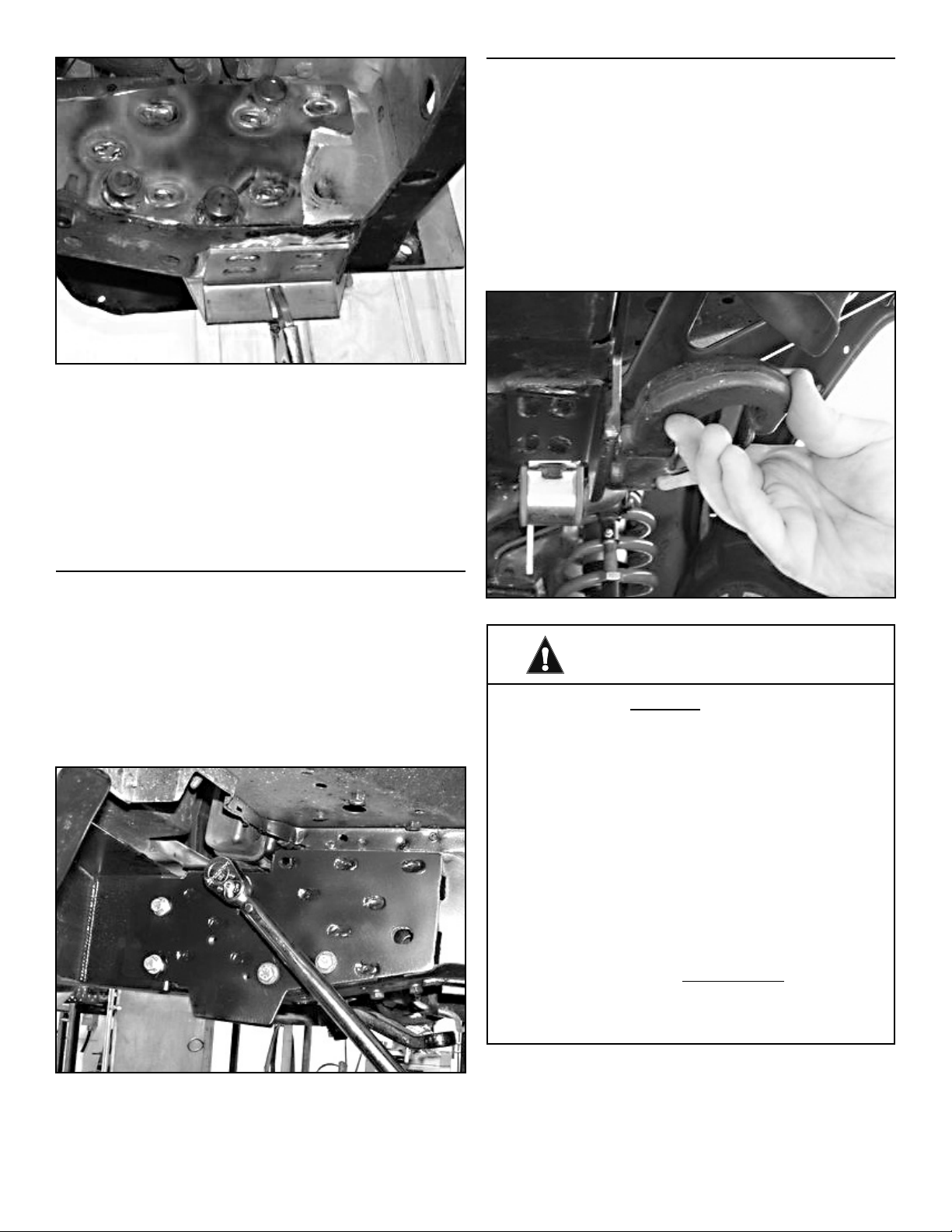

ZUnbolt the steering gear and adapter plate from

the chassis. Temporarily secure the steering gear

out of the way – it should not be necessary to

disconnect uid lines or steering shaft. Discard

steering gear adapter plate.

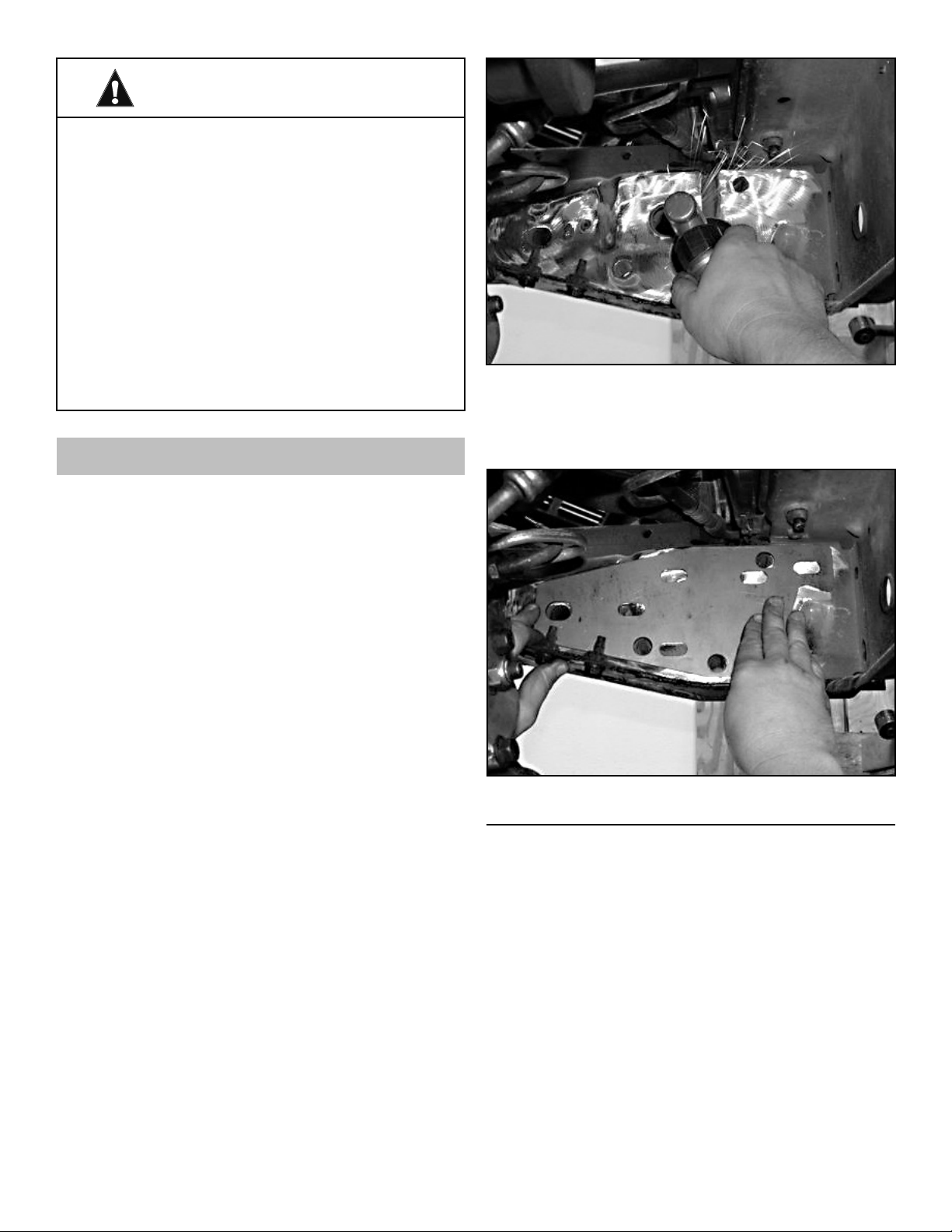

ZTest t the Inner and Outer Chassis Plates (A & B)

to the chassis rail. Mark an outline of each plate

onto chassis surface.

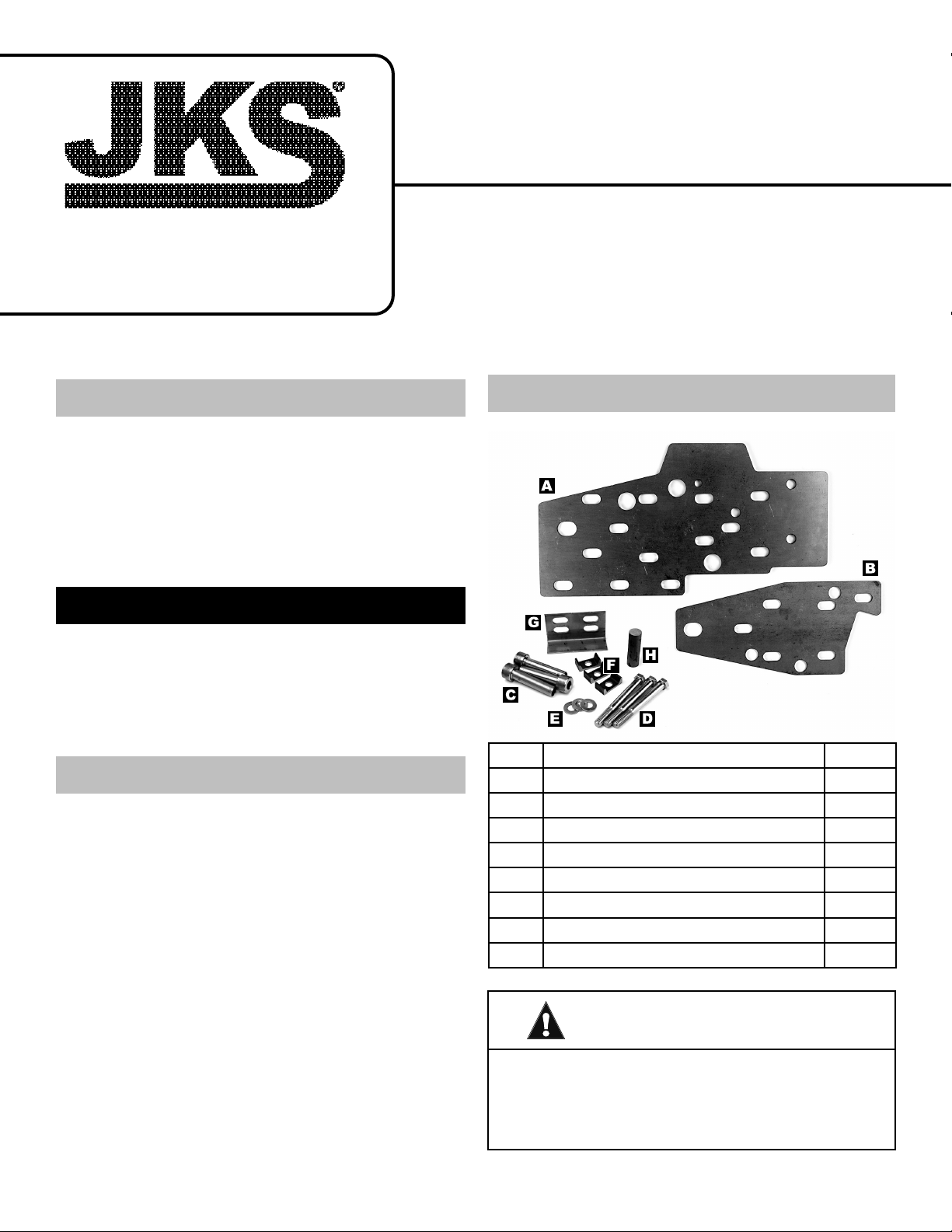

ZCompletely remove all paint/primer, weld slag/

spatter, or other debris from chassis surface

(inboard and outboard side) until bare metal is

exposed.

HINT: A die grinder with sanding wheel, disc

sander, or similar tool is useful for cleaning chas-

sis surface.

ZTest t the Inner and Outer Chassis Plates (A &

B) again to check for ush tment against chassis

surface, and to ensure all debris has been re-

moved from the necessary areas.

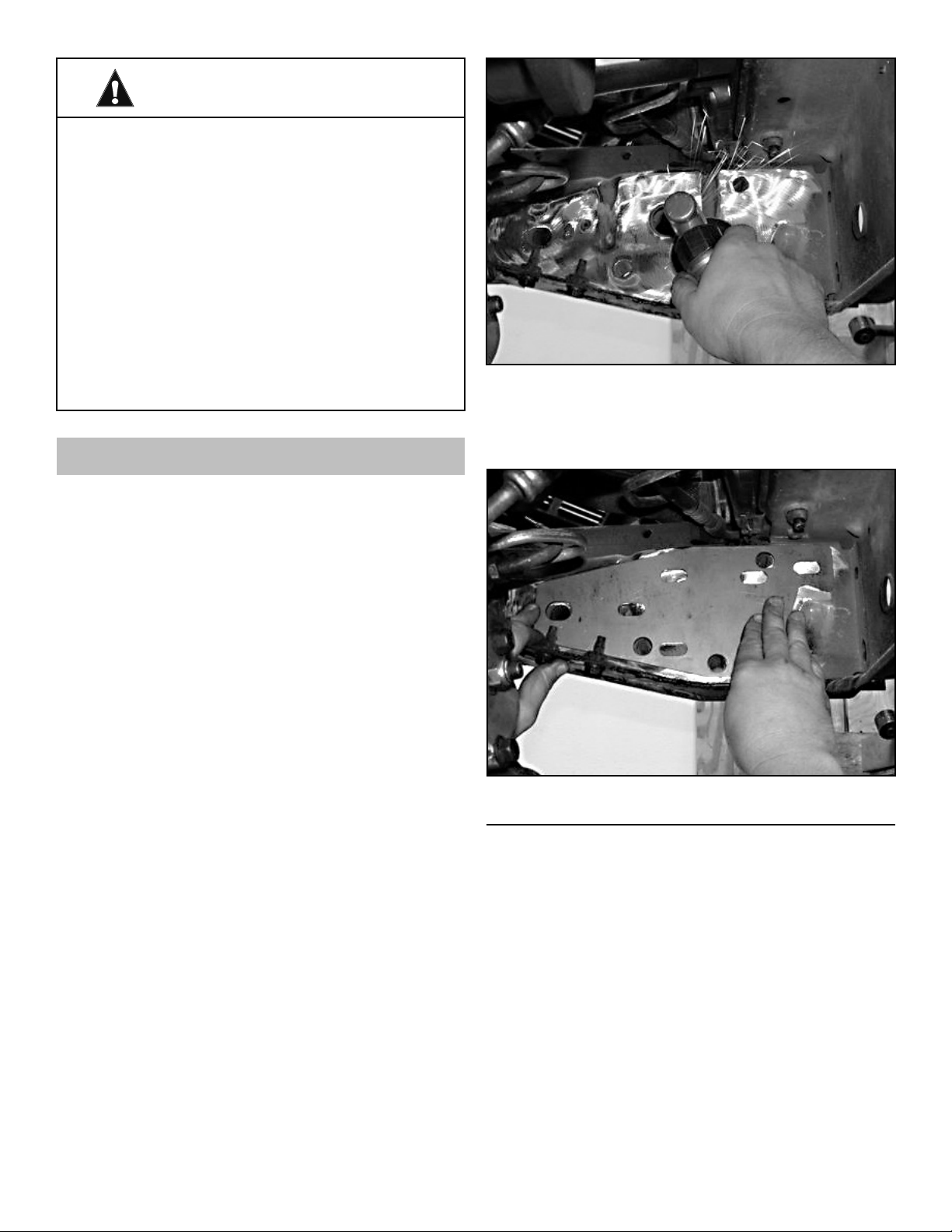

2. ENLARGE STEERING GEAR MOUNTING

HOLES IN CHASSIS

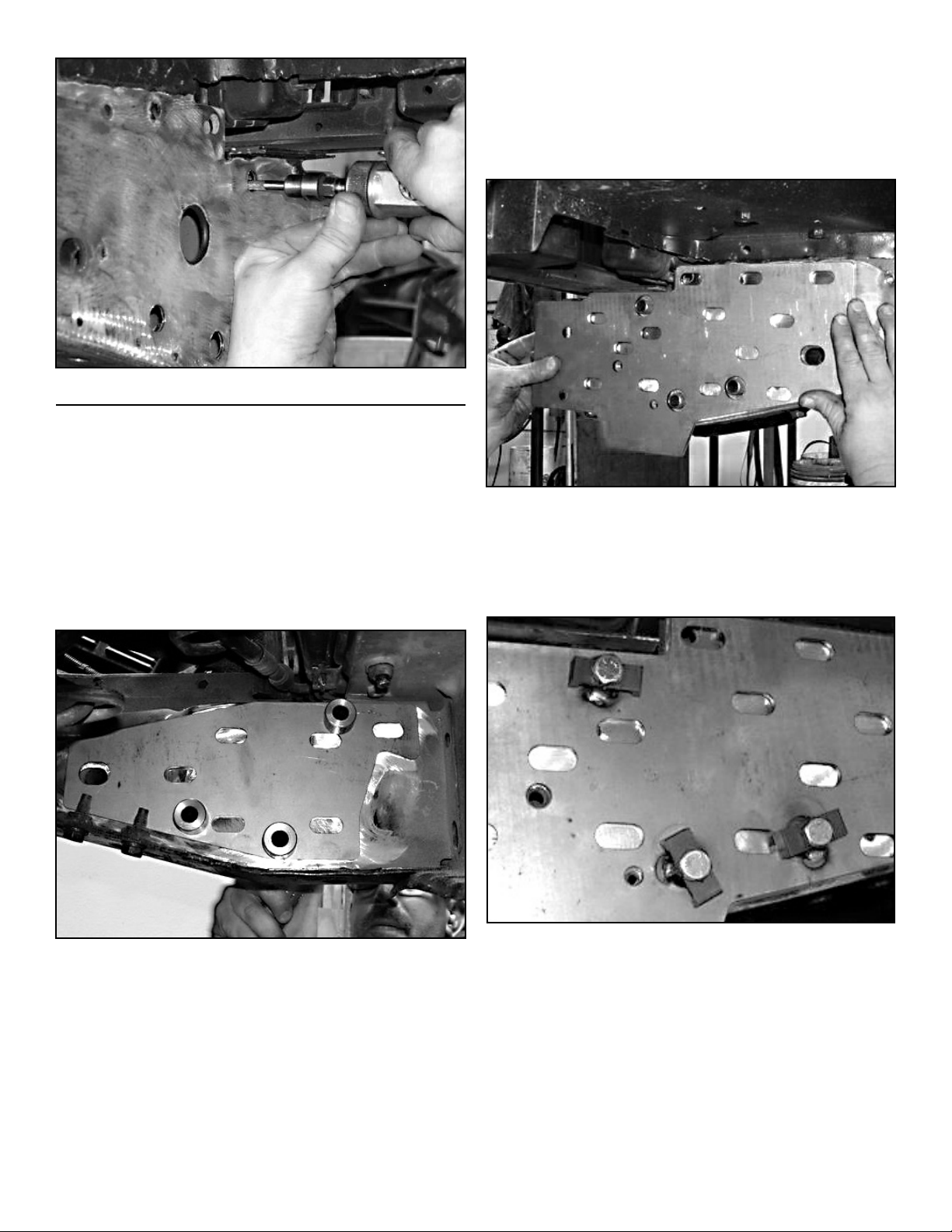

ZLocate the three (3) steering gear mounting holes

on the inboard and outboard side of chassis rail.

ZEnlarge the inboard and outboard mounting holes

to approximately 5/8” – or until narrow end of Sup-

port Sleeves (C) can be inserted.

HINT: A uni-bit (step-drill bit) is useful for enlarging

holes to 5/8” – and more eective on the unibody

chassis than standard drill bits. A pneumatic die

grinder or dremel tool with carbide cutting attach-

ment (shown) is also eective, particularly where

clearance is limited.