Model CV-300B Grooved End

Swing Check Valves

Page 1 of 2 AUGUST 2018 TFP1552

Worldwide

Contacts

www.tyco-fire.com

IMPORTANT

Refer to Technical Data Sheet

TFP2300 for warnings pertaining to

regulatory and health information.

General

Description

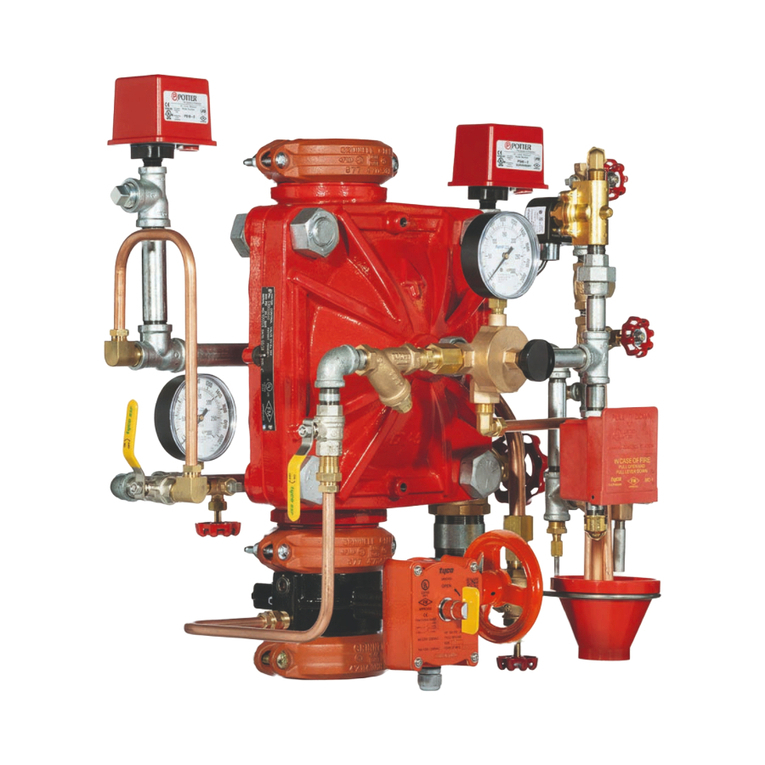

The TYCO Model CV-300B Grooved

End Swing Check Valves are compact

and rugged swing-type units that

allow water flow in one direction and

prevent flow in the opposite direction.

A resilient elastomer seal facing on the

spring-loaded clapper ensures a leak-

tight seal and non-sticking operation.

The Model CV-300B Check Valves are

designed to minimize water hammer

caused by flow reversal.

The Model CV-300B Grooved End

Swing Check Valves are furnished with

grooved ends and can be installed

using GRINNELL

Grooved Couplings

or GRINNELL Figure 71 Flange Adapt-

ers. These valves can be installed hori-

zontally, or vertically with the flow in the

upward direction (Ref. Figure 2).

NOTICE

The TYCO Model CV-300B Grooved

End Swing Check Valves described

herein must be installed and main-

tained in compliance with this docu-

ment and with the applicable standards

of the NATIONAL FIRE PROTECTION

ASSOCIATION (NFPA), in addition to

the standards of any authorities having

jurisdiction. Failure to do so may impair

the performance of these devices.

Never remove any piping component

nor correct or modify any piping defi-

ciencies without first de-pressurizing

and draining the system. Failure to do

so may result in serious personal injury,

property damage, and/or impaired

device performance.

The owner is responsible for main-

taining their fire protection system

and devices in proper operating con-

dition. Contact the installing contrac-

tor or product manufacturer with any

questions.

Technical

Data

Approvals

UL and ULC Listed

FM Approved

Sizes

4 in. (DN100)

Maximum Working Pressure

300 psi (20,7 bar)

Valve Assembly Finish

Red, non-lead paint

Weight

19.84 lbs (9 kg)

Installation

The Model CV-300B Grooved End

Swing Check Valves are to be installed

in accordance with this section:

Step 1. The arrow cast on the body

must point in the direction of the flow

(Ref. Figure 2):

Vertical installation - orient the valve

with the flow arrow pointed up

Horizontal installation - orient the

valve with the large boss facing

either up or down, and the flow arrow

pointed left or right

Step 2. Grooved end pipe couplings

used with the Model CV-300B Grooved

End Swing Check Valves must be

installed in accordance with manufac-

turer’s instructions.

Note: Valves should be installed a rea-

sonable distance downstream from

pumps, elbows, expanders, reducers,

or other similar devices to extend the

valve life. Standard piping practices call

for a minimum of five (5) times the pipe

diameter for general use.

Care and

Maintenance

The TYCO Model CV-300B Grooved

End Swing Check Valves must be main-

tained and serviced in accordance with

this section.

Before closing a fire protection system

main control valve for maintenance

work on the fire protection system

that it controls, obtain permission to

shut down the affected fire protection

system from the proper authorities

and notify all personnel who may be

affected by this decision.

After placing a fire protection system

in service, notify the proper authorities

and advise those responsible for moni-

toring proprietary and/or central station

alarms.

The owner is responsible for the

inspection, testing, and maintenance of

their fire protection system and devices

in compliance with this document, as

well as with the applicable standards

of the NATIONAL FIRE PROTECTION

ASSOCIATION (e.g., NFPA 25), in addi-

tion to the standards of any authority

having jurisdiction. Contact the install-

ing contractor or product manufacturer

with any questions. Any impairments

must be immediately corrected.

Automatic sprinkler systems are rec-

ommended to be inspected, tested,

and maintained by a qualified Inspec-

tion Service in accordance with local

requirements and/or national codes.

For re protection pressure rating,

listing and approval information, contact

your TYCO representative.