Worldwide

Contacts

www.tyco-fire.com

Summary Instructions

DV-5AAutomatic Water Control Valve

Deluge Fire Protection Systems

Wet Pilot Actuation Trim

1400 Pennbrook Parkway, Lansdale, PA 19446 | Telephone +1-215-362-0700

© 2021 Johnson Controls. All rights reserved. All specifications and other information shown were current as of document

revision date and are subject to change without notice.

TFP1311 Appendix A

APRIL 2021

Valve Setting Procedure

1. Close System Main Control Valve (B) and Diaphragm Supply Valve (P).

2. Open the Main Drain Valve (D), System Drain Valve (E), and all auxiliary drains in the system.

Close the auxiliary drain valves and the System Drain Valve (E) after water stops discharging.

Leave the Main Drain Valve (D) open. Ensure that the Pressure Gauge Valves and the Alarm

Control Valve (H) are open.

3. Depress plunger of Automatic Drain Valve (F) to verify it is open.

4. Clean Diaphragm Supply Strainer (Q). Flush strainer by opening the Diaphragm Supply

Valve (P).

5. Replace operated pilot sprinklers and/or reset remote manual control stations.

6. Open Manual Control Station (M) and Diaphragm Supply Valve (P). After water stops dis-

charging, slowly close the operating lever. Do not close the hinged cover at this time.

7. After water stops discharging, reset the Manual Reset Actuator (N) until water stops flowing

from its drain tube and pressure reaches approximately 15 psi (1,0 bar) on Diaphragm Gauge

(K).

8. Crack open Inspector’s Test Connection and any other vent valves. After air has stopped

discharging, close vent valves and Inspector’s Test Connection.

9. With diaphragm chamber pressurized, temporarily close Diaphragm Supply Valve (P) and

observe Diaphragm Gauge (K) for a drop in pressure. If a pressure drop is noted, replace

DV-5ADiaphragm and correct any leaks before proceeding.

10. If Diaphragm Gauge (K) indicates no drop in pressure, re-open the Diaphragm Supply

Valve (P) and proceed.

11. Partially open System Main Control Valve (B). Slowly close Main Drain Valve (D) as water

discharges from Main Drain Valve (D). Observe Automatic Drain Valve (F) for leaks. If there

are leaks, correct the leakage problem.

12. Close hinged cover of Manual Control Station (M). Insert a new break rod in the small hole

through the top of the enclosing box.

13. Open System Main Control Valve (B).

14. After setting fire protection system, notify proper authorities and advise those responsible

for monitoring proprietary and/or central station alarms.

Drop in Water Supply Pressure Below Normal Range

1. Note water supply pressure by the Diaphragm Gauge (K) and determine if the pressure is

within normally expected range.

2. If below normal range, correct any leakage from diaphragm chamber prior to resetting the

system.

3. When water supply pressure is restored, reset DV-5AValve in accordance with the Valve

Setting Procedure.

Waterow Alarm Test Procedure

1. Open Alarm Test Valve (G), allowing water to flow to Waterflow Pressure Switch (C) and/or

Water Motor Alarm. Close the Alarm Test Valve (G) when test is completed.

2. Depress plunger on Automatic Drain Valve (F) to drain alarm line.

Wet Pilot Actuation Operation Test Procedure

1. Close System Main Control Valve (B).

2. Open Main Drain Valve (D).

3. Open System Main Control Valve (B) one turn beyond position at which water just begins

to flow from Main Drain Valve (D).

4. Slowly close Main Drain Valve (D).

5. Open Inspector’s Test Connection.

6. Verify DV-5aValve has tripped, as indicated by the flow of water into system.

7. Close System Main Control Valve (B).

8. Close Diaphragm Supply Valve (P).

9. Reset DV-5aValve in accordance with Valve Setting Procedure.

Internal Valve Inspection

1. Ensure that Steps 1 to 4 of the Valve Setting Procedure are completed prior to proceeding

with the Internal Valve Inspection.

2. Ensure Diaphragm Supply Valve (P) is closed. If provided as part of the valve trim, close

Inverted Flare Shut-Off Valve (R).

3. Remove the Supply Line between the Diaphragm Supply Valve (P) and the System Main

Control Valve (B). If provided as part of the valve trim, remove the Supply Line between the

Diaphragm Supply Valve (P) and Inverted Flare Shut-Off Valve (R).

4. Loosen union securing Actuation Trim and remove Actuation Trim.

5. Remove union between Diaphragm Cover and MRA-1 Manual Reset Actuator (N). Remove

MRA-1 Manual Reset Actuator (N) subassembly.

6. Remove Diaphragm Valve Cover hardware, slowly remove Diaphragm Cover and perform

internal valve inspection. Clean valve interior and replace parts as necessary.

7. Ensure Diaphragm is properly oriented and proper hardware arrangement is utilized.

8. Insert Long Hex Bolts. Align Diaphragm with Valve Body, and then align Diaphragm Cover

with Valve Body. Insert Short Hex Bolts. Hand-tighten all fasteners.

9. Using crossdraw sequence, wrench-tighten Long Hex Bolts and Short Hex Bolts. Repeat

crossdraw sequence two to three times at incremental torque valves.

10. Inspect to assure all Hex Bolts are securely tightened.

11. Using the union, secure the MRA-1 Manual Reset Actuator (N) to the Diaphragm Cover.

12. Using union, secure Actuation Trim.

13. Replace the Supply Line between the Diaphragm Supply Valve and the System Main

Control Valve (B). If provided as part of the valve trim, replace Supply Line between Diaphragm

Supply Valve (P) and Inverted Flare Shut-Off Valve (R).

14. Ensure unions and flare fittings are securely tightened.

15. If provided with the valve trim, and with Diaphragm Supply Valve (P) closed, fully open

Inverted Flare Shut-Off Valve (R) stainless steel screw (approximately 1/2 in.) until resistance

is met.

16. Proceed with Step 5 of the Valve Setting Procedures.

NOTICE

The procedures provided are summary instructions of the complete procedures appearing

in Technical Data Sheet TFP1311. If problems occur, consult full document.

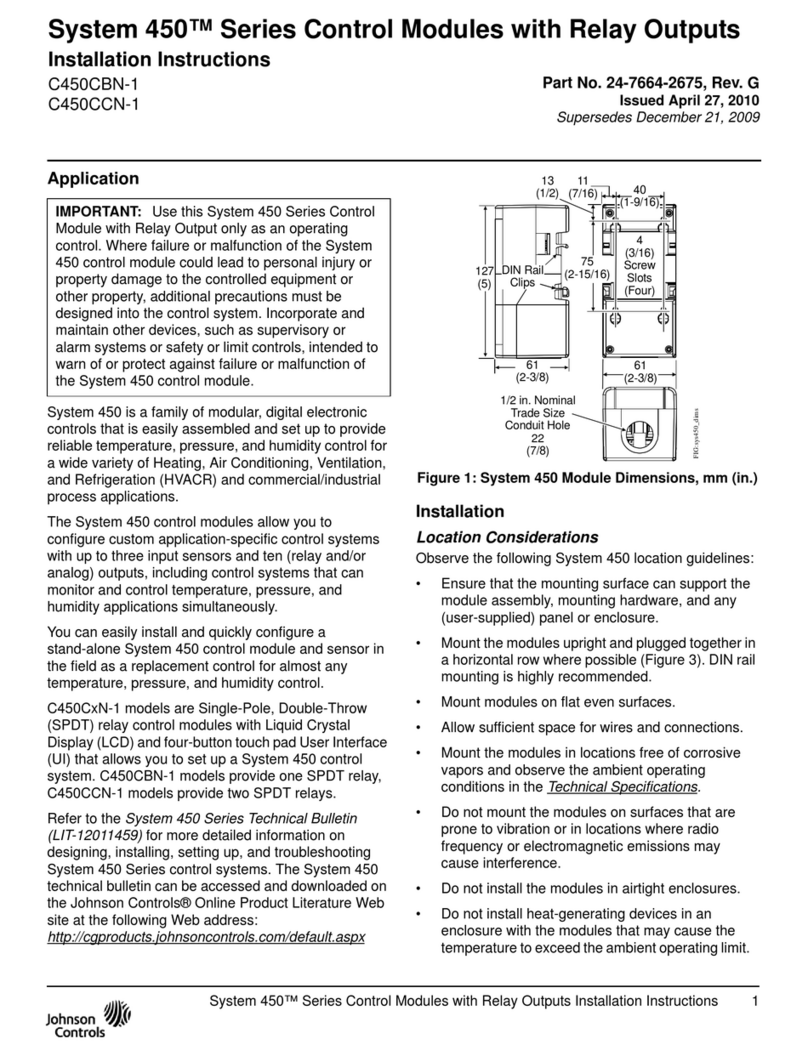

Item Description

A

B

C

D

E

F

G

H

DV-5aValve

System Main Control Valve

Waterow Pressure Switch

Main Drain Valve

System Drain Valve

Automatic Drain Valve

Alarm Test Valve

Alarm Control Valve (Optional)

Item Description

J

K

L

M

N

P

Q

R

Water Supply Gauge

Diaphragm Gauge

System Gauge (Optional)

Manual Control Station

Manual Reset Actuator

Diaphragm Supply Valve

Diaphragm Supply Strainer

Inverted Flare Shut-Off Valve

A

B

JK

D

E

F

G

M

N

P

Q

L

C

H

R

Worldwide

Contacts

www.tyco-fire.com

Summary Instructions

DV-5AAutomatic Water Control Valve

Deluge Fire Protection Systems

Wet Pilot Actuation Trim

1400 Pennbrook Parkway, Lansdale, PA 19446 | Telephone +1-215-362-0700

© 2021 Johnson Controls. All rights reserved. All specifications and other information shown were current as of document

revision date and are subject to change without notice.

TFP1311 Appendix A

APRIL 2021

Valve Setting Procedure

1. Close System Main Control Valve (B) and Diaphragm Supply Valve (P).

2. Open the Main Drain Valve (D), System Drain Valve (E), and all auxiliary drains in the system.

Close the auxiliary drain valves and the System Drain Valve (E) after water stops discharging.

Leave the Main Drain Valve (D) open. Ensure that the Pressure Gauge Valves and the Alarm

Control Valve (H) are open.

3. Depress plunger of Automatic Drain Valve (F) to verify it is open.

4. Clean Diaphragm Supply Strainer (Q). Flush strainer by opening the Diaphragm Supply

Valve (P).

5. Replace operated pilot sprinklers and/or reset remote manual control stations.

6. Open Manual Control Station (M) and Diaphragm Supply Valve (P). After water stops dis-

charging, slowly close the operating lever. Do not close the hinged cover at this time.

7. After water stops discharging, reset the Manual Reset Actuator (N) until water stops flowing

from its drain tube and pressure reaches approximately 15 psi (1,0 bar) on Diaphragm Gauge

(K).

8. Crack open Inspector’s Test Connection and any other vent valves. After air has stopped

discharging, close vent valves and Inspector’s Test Connection.

9. With diaphragm chamber pressurized, temporarily close Diaphragm Supply Valve (P) and

observe Diaphragm Gauge (K) for a drop in pressure. If a pressure drop is noted, replace

DV-5ADiaphragm and correct any leaks before proceeding.

10. If Diaphragm Gauge (K) indicates no drop in pressure, re-open the Diaphragm Supply

Valve (P) and proceed.

11. Partially open System Main Control Valve (B). Slowly close Main Drain Valve (D) as water

discharges from Main Drain Valve (D). Observe Automatic Drain Valve (F) for leaks. If there

are leaks, correct the leakage problem.

12. Close hinged cover of Manual Control Station (M). Insert a new break rod in the small hole

through the top of the enclosing box.

13. Open System Main Control Valve (B).

14. After setting fire protection system, notify proper authorities and advise those responsible

for monitoring proprietary and/or central station alarms.

Drop in Water Supply Pressure Below Normal Range

1. Note water supply pressure by the Diaphragm Gauge (K) and determine if the pressure is

within normally expected range.

2. If below normal range, correct any leakage from diaphragm chamber prior to resetting the

system.

3. When water supply pressure is restored, reset DV-5AValve in accordance with the Valve

Setting Procedure.

Waterow Alarm Test Procedure

1. Open Alarm Test Valve (G), allowing water to flow to Waterflow Pressure Switch (C) and/or

Water Motor Alarm. Close the Alarm Test Valve (G) when test is completed.

2. Depress plunger on Automatic Drain Valve (F) to drain alarm line.

Wet Pilot Actuation Operation Test Procedure

1. Close System Main Control Valve (B).

2. Open Main Drain Valve (D).

3. Open System Main Control Valve (B) one turn beyond position at which water just begins

to flow from Main Drain Valve (D).

4. Slowly close Main Drain Valve (D).

5. Open Inspector’s Test Connection.

6. Verify DV-5aValve has tripped, as indicated by the flow of water into system.

7. Close System Main Control Valve (B).

8. Close Diaphragm Supply Valve (P).

9. Reset DV-5aValve in accordance with Valve Setting Procedure.

Internal Valve Inspection

1. Ensure that Steps 1 to 4 of the Valve Setting Procedure are completed prior to proceeding

with the Internal Valve Inspection.

2. Ensure Diaphragm Supply Valve (P) is closed. If provided as part of the valve trim, close

Inverted Flare Shut-Off Valve (R).

3. Remove the Supply Line between the Diaphragm Supply Valve (P) and the System Main

Control Valve (B). If provided as part of the valve trim, remove the Supply Line between the

Diaphragm Supply Valve (P) and Inverted Flare Shut-Off Valve (R).

4. Loosen union securing Actuation Trim and remove Actuation Trim.

5. Remove union between Diaphragm Cover and MRA-1 Manual Reset Actuator (N). Remove

MRA-1 Manual Reset Actuator (N) subassembly.

6. Remove Diaphragm Valve Cover hardware, slowly remove Diaphragm Cover and perform

internal valve inspection. Clean valve interior and replace parts as necessary.

7. Ensure Diaphragm is properly oriented and proper hardware arrangement is utilized.

8. Insert Long Hex Bolts. Align Diaphragm with Valve Body, and then align Diaphragm Cover

with Valve Body. Insert Short Hex Bolts. Hand-tighten all fasteners.

9. Using crossdraw sequence, wrench-tighten Long Hex Bolts and Short Hex Bolts. Repeat

crossdraw sequence two to three times at incremental torque valves.

10. Inspect to assure all Hex Bolts are securely tightened.

11. Using the union, secure the MRA-1 Manual Reset Actuator (N) to the Diaphragm Cover.

12. Using union, secure Actuation Trim.

13. Replace the Supply Line between the Diaphragm Supply Valve and the System Main

Control Valve (B). If provided as part of the valve trim, replace Supply Line between Diaphragm

Supply Valve (P) and Inverted Flare Shut-Off Valve (R).

14. Ensure unions and flare fittings are securely tightened.

15. If provided with the valve trim, and with Diaphragm Supply Valve (P) closed, fully open

Inverted Flare Shut-Off Valve (R) stainless steel screw (approximately 1/2 in.) until resistance

is met.

16. Proceed with Step 5 of the Valve Setting Procedures.

NOTICE

The procedures provided are summary instructions of the complete procedures appearing

in Technical Data Sheet TFP1311. If problems occur, consult full document.

Item Description

A

B

C

D

E

F

G

H

DV-5aValve

System Main Control Valve

Waterow Pressure Switch

Main Drain Valve

System Drain Valve

Automatic Drain Valve

Alarm Test Valve

Alarm Control Valve (Optional)

Item Description

J

K

L

M

N

P

Q

R

Water Supply Gauge

Diaphragm Gauge

System Gauge (Optional)

Manual Control Station

Manual Reset Actuator

Diaphragm Supply Valve

Diaphragm Supply Strainer

Inverted Flare Shut-Off Valve

A

B

JK

D

E

F

G

M

N

P

Q

L

C

H

R