Model TFP PH2 — 5.6 K-factor

Institutional Pendent Sprinklers

Standard Response, Standard Coverage

Page 1 of 4 AUGUST 2018 TFP650

IMPORTANT

Refer to Technical Data Sheet

TFP2300 for warnings pertaining to

regulatory and health information.

Always refer to Technical Data

Sheet TFP700 for the “INSTALLER

WARNING” that provides cautions

with respect to handling and instal-

lation of sprinkler systems and com-

ponents. Improper handling and

installation can permanently damage

a sprinkler system or its compo-

nents and cause the sprinkler to fail

to operate in a fire situation or cause

it to operate prematurely.

Worldwide

Contacts

www.tyco-fire.com

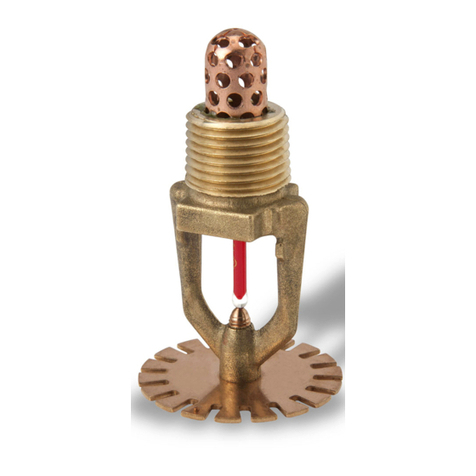

General

Description

The TYCO Model TFP PH2, 5.6 K-fac-

tor, Institutional Pendent Sprinklers are

standard response standard coverage,

fusible solder type spray sprinklers

designed for use in areas such as cor-

rectional, detention, and mental health

care facilities.

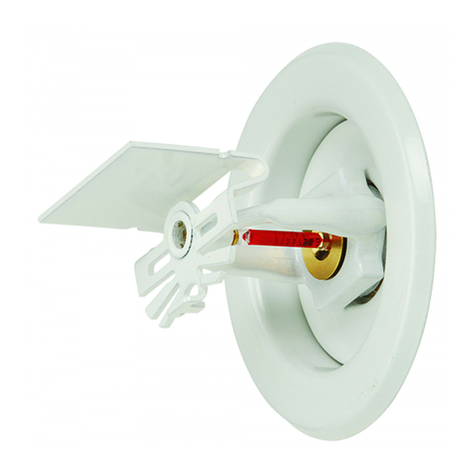

The unique features of the Model TFP

PH2 provide a tamper resistant sprin-

kler design that helps eliminate the

opportunity for individuals to injure

themselves or others with the compo-

nents of a fire sprinkler. At the same

time, the Model TFP PH2 optimizes an

aesthetically appealing flush design

that conceals most of the operating

parts.

NOTICE

The Model TFP PH2 Institutional Pendent

Sprinklers described herein must be

installed and maintained in compliance

with this document, as well as with the

applicable standards of the NATIONAL

FIRE PROTECTION ASSOCIATION, in

addition to the standards of any other

authorities having jurisdiction. Failure to

do so may impair the performance of

these devices.

The owner is responsible for maintaining

their fire protection system and devices

in proper operating condition. Contact

the installing contractor or product

manufacturer with any questions.

Sprinkler

Identification

Number (SIN)

TY3290

Technical

Data

Approvals

UL and C-UL Listed

NYC under MEA 351-01-E

(Refer to the Design Criteria section.)

Maximum Working Pressure

175 psi (12,1 bar)

Inlet Thread Connection

1/2 in. NPT

Discharge Coefficient

K=5.6 GPM/psi½(80,6 LPM/bar½)

Temperature Ratings

165°F (74°C) or

212°F (100°C)

Finishes

Sprinkler: Chrome Plated

Escutcheon: Chrome Plated

Physical Characteristics

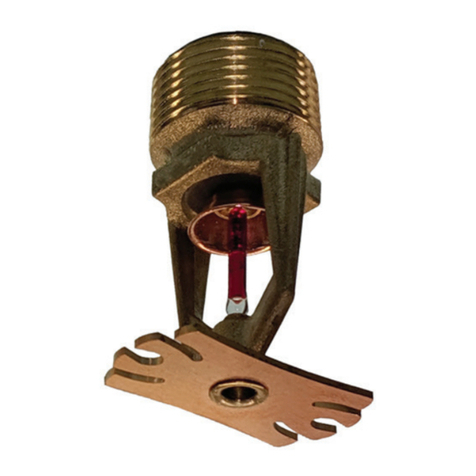

Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Brass

Deflector . . . . . . . . . . . . . . . . . . . . . . . . . .Bronze

Deflector Reinforcement Bronze

Deflector Post . . . . . . . . . . . . . . . . . . . . . .Bronze

Deflector Post Pin . . . . . . . . . . . . . . . . . . .Bronze

Deflector Core. . . . . . . . . . . . . . . . . . . . . .Bronze

Compression Screw . . . . . . . . . . . . . . . . .Bronze

Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Bronze

Release Spring . . . . . . . . . . . . . . . . . . . . .Bronze

Core Sleeve. . . . . . . . . . . . . . . . . . . . . . . Copper

Sealing Assembly . Beryllium Nickel w/ TEFLON

Dust Cover .............Chrome Plated Steel

Fusible Element . . . . . . . . . . . . .Solder, Copper,

Stainless Steel

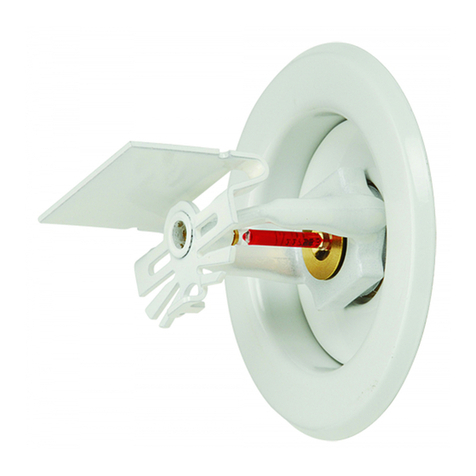

Operation

In the standby condition, the design

of the Model TFP PH2 is such that a

dynamic load of 80 lb (36 kg) or more

applied to the linkage mechanism will

release the sprinkler. Also, when prop-

erly installed, the escutcheon is held

fast to the ceiling to deter its removal.

The shape of the escutcheon cannot

be easily grasped, which further deters

tampering.

A fusible solder operating element

secures the linkage mechanism of the

Model TFP PH2. When the rated tem-

perature is reached, the solder melts,

releasing the linkage mechanism that

holds the sprinkler closed. This allows

the deflector to extend downward and

water to flow.

Design

Criteria

The TYCO Model TFP PH2, 5.6 K-fac-

tor, Institutional Pendent Sprinklers

(TY3290) are intended for use with

fire protection systems designed in

accordance with the standard instal-

lation rules recognized by the appli-

cable Listing or Approval agency (for

example, Listing is based on NFPA 13

requirements).