FlexSys Underoor Air Terminal (Variable Volume)

MIT3 - CN

Model:

©2016 Johnson Controls | The performance specications are nominal and conform to acceptable industry standards. For applications at conditions beyond these specications, consult the local

Johnson Controls ofce. Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products.

© 2016 AirFixture, LLC

2

Installation / Operation Manual

V160803

INSTALLATION (CONTINUED):

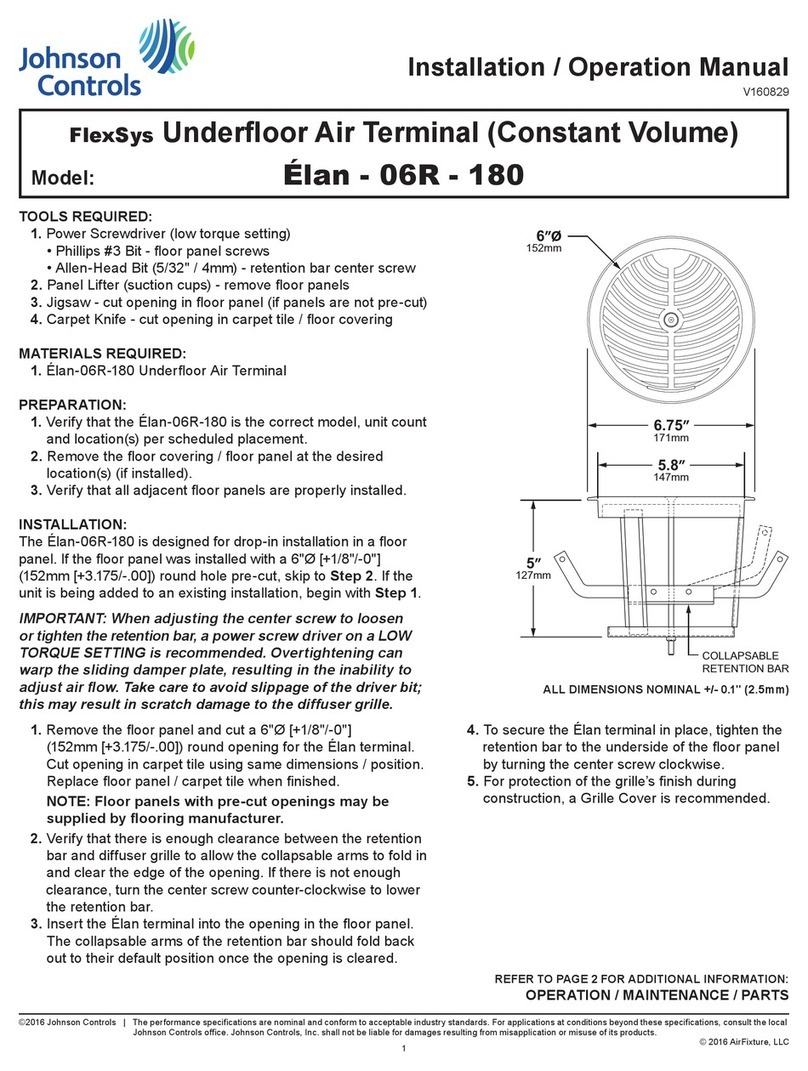

1. Remove oor panel and cut 10-1/2" x 5-1/2" [+1/8"/-0"]

(267mm x 140mm [+3.175/-.00]) rectangle opening for MIT

terminal. Cut opening in carpet tile using same dimensions /

position.

NOTE: Floor panels with pre-cut openings may be

supplied by ooring manufacturer.

2. Remove trim ring and grille insert from MIT terminal. Remove

package of trim ring screws from interior of terminal (screws

may be provided in a separate box on shipping pallet).

3. Set MIT terminal on work surface. Lay oor panel on top of

terminal, so that rectangle collar ts through pre-cut opening.

Place carpet tile in position on top of oor panel.

4. Insert trim ring into MIT terminal.

IMPORTANT: Align trim ring screw holes with

corresponding holes on sides of rectangle collar.

5. Secure trim ring to MIT terminal, using included screws to

hold assembly together.

6. Replace oor panel (with installed MIT terminal / trim ring).

Orient panel so that air valve opening is directed away from

exterior walls.

7. Connect MIT terminal to designated VAV operational zone,

using Plug & Play Cables connected to molex inputs located

on air valve actuator.

8. Conrm air valve operation – spin damper by hand to verify

it is free to move. Incorrect routing of cables and other

underoor obstructions can interfere with operation.

9. Replace oor panel screws to secure oor panel / MIT

assembly in place.

10. Place grille insert into trim ring in desired orientation.

OPTIONAL: Tighten security screws (if provided).

11. For protection of diffuser grille nish during construction,

a Grille Cover is recommended.

Use only #8 Phillips Head Sheet Metal Screws.

Using other screws could void warranty.

OPERATION:

Once installed, the MIT3-CN requires no

direct input or adjustment for proper operation.

MAINTENANCE:

At least once a year, it is recommended to

clean the interior of the MIT3-CN terminal.

1. Remove grille insert, and carefully vacuum

any loose debris from interior of terminal.

2. After cleaning, replace grille insert.

PARTS:

• Grille Cover: P/N 620.0120.05