SECTION 1: IMPORTANT SAFE OPERATION PRACTICES

WARNING: This symbol points out important safety instructions which, if not followed, could endanger

the personal safety and/or property of yourself and others. Read and follow all instructions in this manual

before attempting to operate this machine. Failure to comply with these instructions may result in personal

injury. When you see this symbol - heed its warning.

WARNING: The Engine Exhaust from this product contains chemicals known to the State

of California to cause cancer, birth defects or other reproductive harm.

DANGER: This machine was built to be operated according to the rules for safe operation in this manual.

As with any type of power equipment, carelessness or error on the part of the operator can result in serious

injury. This machine is capable of amputating hands and feet and throwing objects. Failure to observe the

following safety instructions could result in serious injury or death.

Training

1. Read, understand, and follow all instructions on the

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in a safe place

for future and regular reference and for ordering

replacement parts.

2. Be familiar with all controls and their proper operation.

Know how to stop the machine and disengage them

quickly.

3. Never allow children under 16 years old to operate this

machine. Children 16 years old and over should read and

understand the operation instructions and safety rules in

this manual and should be trained and supervised by a

parent.

4. Never allow adults to operate this machine without

proper instruction.

5. Keep bystanders, helpers, pets, and children at least 75

feet from the machine while it is in operation. Stop

machine if anyone enters the area.

6. Never run an engine indoors or in a poorly ventilated

area. Engine exhaust contains carbon monoxide, an

odorless and deadly gas.

7. Do not put hands and feet near rotating parts or in the

feeding chambers and discharge opening. Contact with

the rotating impeller can amputate fingers, hands, and

feet.

8. Never attempt to unclog either the feed intake or

discharge opening, remove or empty vacuum bag, or

inspect and repair the machine while the engine is

running. Shut the engine off and wait until all moving

parts have come to a complete stop. Disconnect the

spark plug wire and ground it against the engine.

Preparation

1. Thoroughly inspect the area where the equipment is to

be used. Remove all rocks, bottles, cans, or other foreign

objects which could be picked up or thrown and cause

personal injury or damage to the machine.

2. Always wear safety glasses or safety goggles during

operation or while performing an adjustment or repair, to

protect eyes. Thrown objects which ricochet can cause

serious injury to theeyes.

3. Wear sturdy, rough-soled work shoes and close-fitting

slacks and shirts. Loose fitting clothes or jewelry can be

caught in movable parts. Never operate this machine in

bare feet or sandals. Wear leather work gloves when

feeding material in the chipper chute.

4. Before starting, check all bolts and screws for proper

tightness to be sure the machine is in safe working

condition. Also, visually inspect machine for any damage

at frequent intervals.

5. Maintain or replace safety and instructions labels, as

necessary.

6. To avoid personal injury or property damage use extreme

care in handling gasoline. Gasoline is extremely

flammable and the vapors are explosive. Serious

personal injury can occur when gasoline is spilled on

yourself or your clothes which can ignite. Wash your skin

and change clothes immediately.

a. Use only an approved gasoline container.

b. Extinguish all cigarettes, cigars, pipes, and other

sources of ignition.

c. Never fuel machine indoors.

d. Never remove gas cap or add while the engine is

hot or running.

e. Allow engine to cool at least two minutes before

refueling.

f. Never over fill fuel tank. Fill tank to no more than

1/2 inch below bottom of filler neck to provide

space for fuel expansion.

g. Replace gasoline cap and tighten securely.

h. If gasoline is spilled, wipe it off the engine and

equipment. Move machine to another area. Wait 5

minutes before starting engine.

i. Never store the machine or fuel container inside

where there is an open flame, spark, or pilot light

(e.g. furnace, water heater, space heater, clothes

dryer, etc.)

j. To reduce a fire hazard, keep machine free of

grass, leaves, or other debris build-up. Clean up

oil or fuel spillage and remove any fuel soaked

debris.

k. Allow machine to cool at least 5 minutes before

storing.

Operation

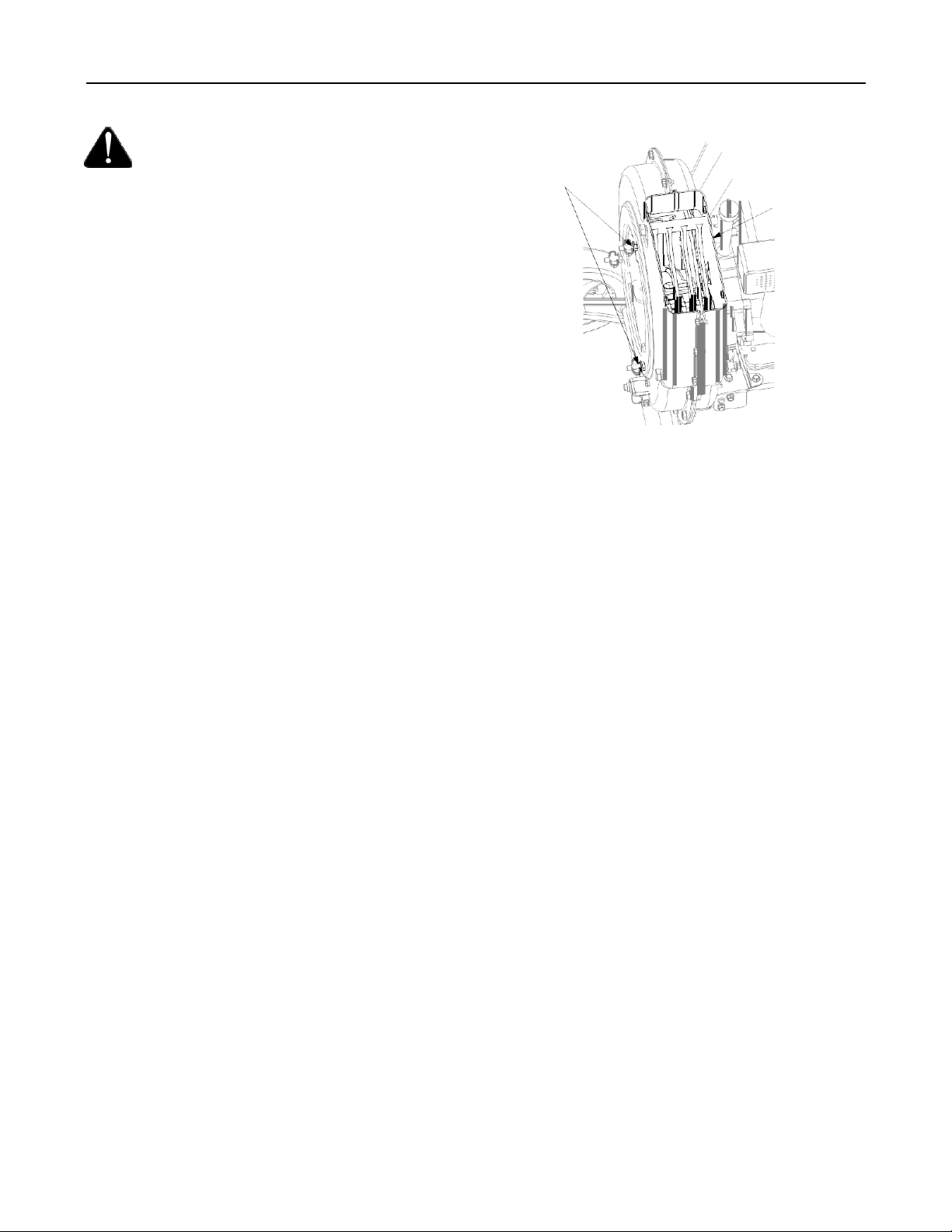

1. Do not put hands and feet near rotating parts or in the

feeding chambers and discharge opening. Contact with

the rotating impeller can amputate fingers, hands, and

feet.