Original Instructions: Basic Info

Please always refer to the www.prusa3d.com/drivers/

for an updated version of this 3D printing handbook (PDF download).

Failure to read the handbook may lead to personal injury, inferior results, or damage to the 3D printer. Always ensure that

anyone who operates the 3D printer knows and understands the contents of the Manual/Handbook. We cannot control the

conditions in which you assemble the Original Prusa MINI. For this, and other reasons, we do not assume responsibility,

and expressly disclaim liability for loss, injuries, damage, or expense arising out of, or in any way connected with, the

assembly, handling, storage, use or disposal of the product. The information in this handbook is provided without any warranty,

expressed or implied, regarding its correctness.

Translated versions of the handbook will be available at:

•Czech: www.prusa3d.cz/ovladace/

•French: www.prusa3d.fr/drivers/

•German: www.prusa3d.de/treiber/

•Polish: prusa3d.pl/sterowniki/

•Italian: www.prusa3d.it/driver/

•Spanish: www.prusa3d.es/drivers-y-manuales/

QUICK GUIDE TO THE FIRST PRINT

1. Read chapter 6 Your First Print carefully

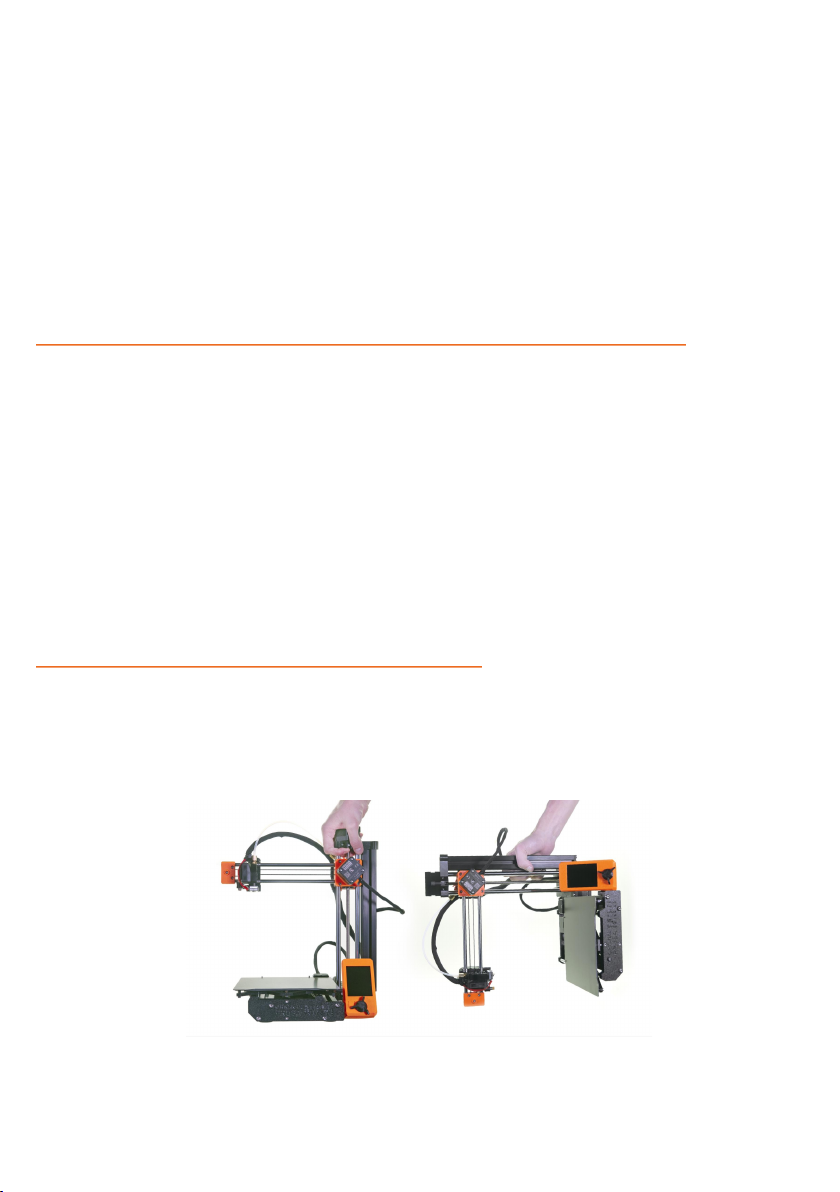

2. Place the assembled printer on a Sat and stable surface

3. ,tart the printerU insert the enclosed B,4 drive and update the Frmware

5. jollow the on-screen instructions to calibrate the printer

I. Print a sample ob!ect

Tmportant noticeU tipU hint or information that helps you print with ease.

Read carefullyx ghis part of the teqt has the @reatest importance - either for user safety or for

proper printer service.

How to contact Prusa Research tech support:

jirstU check the last chapters of this handbook for troubleshootin@ @uidesU or visit help.prusa3d.com

for a complete list of common issuesU print Luality troubleshootin@ and other @uides. Tf your problem

is not listed thereU or the solution does not workU please send an e-mail to supportHprusa3d.com

or use the 0ive chat at shop.prusa3d.com. gry to eqplain your problem as thorou@hly as possible.

Dandbook version 1.81 from 9ecember 1(thU 281)