JUDO i-soft TGA 4 7

Intended use

The water softening system must only be

used as intended in a technically fault-free

state, while maintaining safety and hazard

awareness, and in compliance with the op-

erating instructions.

Ensure that malfunctions are rectified

immediately!

So that the waste water can be safely

drained away both during operation and also

in the event of a possible system defect, the

specifications given in chapter 4.1.1 “Requi-

rements for the place of installation” must be

closely observed!

(see chapter 1.2 “Safety instructions and

dangers due to non-observation”)

The spent regenerating salt is removed from

the water softening columns together with

waste water. Therefore it must not be used

for irrigation or similar purposes.

The designed capacity of the water softening

system is such that it is capable of partially

softening the entire water requirement for a

single or multiple family dwelling as well as

corresponding partial water quantities for hot

water, swimming pool, washing machine and

dishwasher.

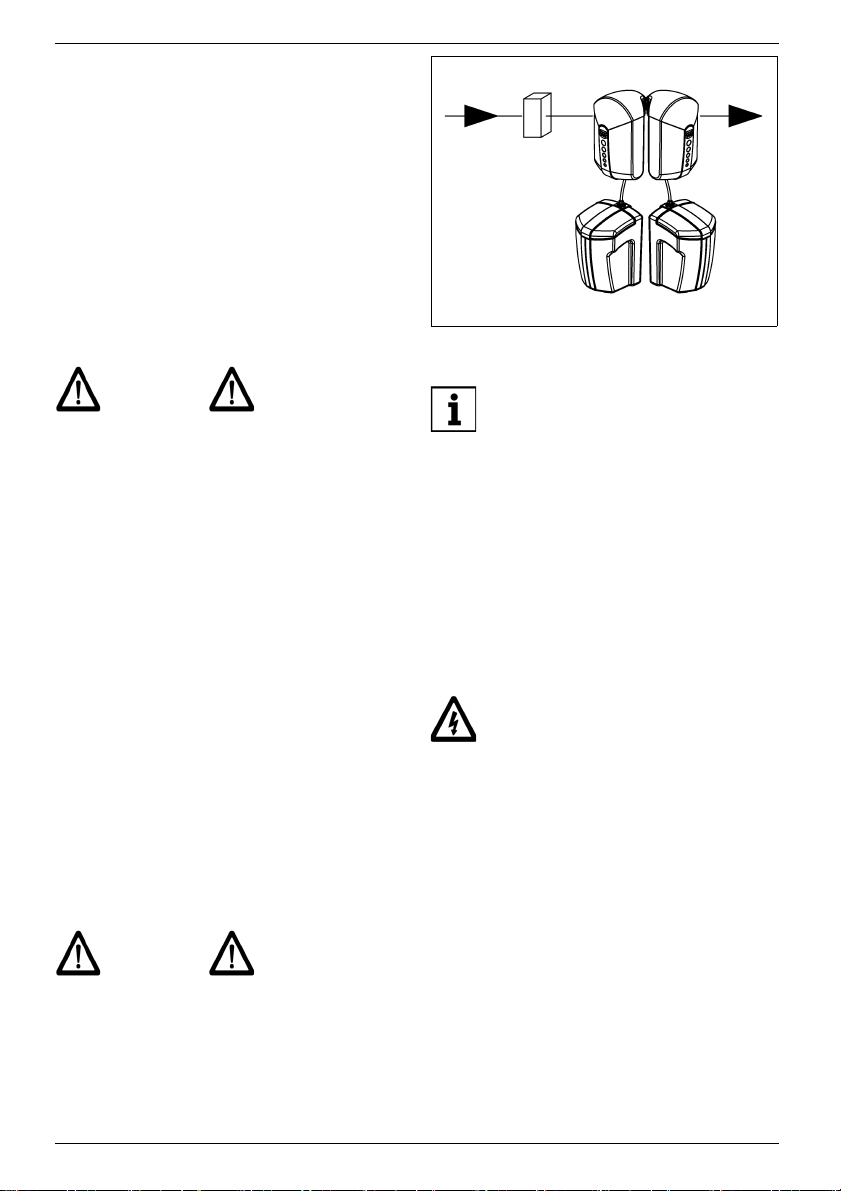

2.1 Water pressure

The water pressure must be between 2 bar

and 7 bar.

The water pressure must not fall below 2 bar

as otherwise the function can be impaired! If

the water softening system is not regularly

serviced, the softening function can be im-

paired.

(see chapter 1.2 “Safety instructions and

dangers due to non-observation”)

Where the water pressure is greater than

7bar, a pressure reducer must be installed

upstream of the water softening system

(see fig. 1)

. If the operating pressure is great-

er than 7 bar, malfunctions can occur.

The optimum operating pressure for the wa-

ter softening system is between 3 bar and

5 bar. This is where it operates most eco-

nomically.

2.2 Indication of particular dan-

gers

2.2.1 Electrical devices/installations

Electrical devices/installations that are not

splash-proof and are located in the vicinity of

the water softening system may be dam-

aged by water that escapes during installa-

tion or in the event of incorrect use of the wa-

ter softening system. If the electrical

devices/installations are connected to the

power supply, it is also possible that a short-

circuit could occur. Should this occur there is

a risk of electric shocks to people. Therefore

electrical devices/furnishings and equip-

ment in the vicinity must be splashproof and/

or comply with the legal regulations for wet

areas.

Fig. 1: Pressure reducer upstream of the sys-

tem

We recommend installation of a

pressure reducer for water pres-

sures between 5 and 7 bar.

No electrical cables and equipment

may be located below or in the im-

mediate vicinity of the water soften-

ing system!