Installation

JUDO QUICKSOFT MEGA 4 9

4Installation

4.1 General

Installation must only be performed by suit-

ably qualified technical personnel.

The chapter 2 “Intended use” must be ob-

served without fail!

The pipe must be able to safely support the

water softening system.

Otherwise mechanical damage to the pipe

up to and including breakage can result.

This can result in severe water damage.

Should such an event occur, persons in the

vicinity of the water softening system are ex-

posed to a risk of injury of harm because of

the large water volumes that could escape.

The supplied support elements are used for

additional support and fixing of the pipe (see

chapter 4.2.3 “Installing the support ele-

ments”).

The spatial requirements of the system can

be found in chapter 9.3 “Installation dimen-

sions”.

At least 300 mm clearance is required

above the water softening system, so that all

maintenance work can be properly per-

formed.

4.1.1 Requirements for the place of

installation

– The ambient temperature must not ex-

ceed 30 °C!

– So that it is possible to safely drain the

waste water (regeneration) during oper-

ation and also in the event that a system

defect occurs, the specifications given in

chapter 4 “Installation” must be precisely

followed!

If the waste water cannot be safely and

completely drained, it is possible that

property damage to the home and fur-

nishings may be caused by the water.

– A shut-off valve must be installed up-

stream and downstream of the water

softening system! This allows the water

supply to be disconnected for water sof-

tening system maintenance, repairs or in

case of malfunction. Likewise flooding

and severe water damage to household

furnishings and equipment can be avoid-

ed in this way.

– The installation room must be dry and

free from frost. Unauthorised persons

must not be able to access the water sof-

tening system.

– The water softening system must not be

subject to severe impacts.

– The device can be installed in all com-

mercially available drinking water pipes.

– Installation of the water softening system

upstream of the water meter is forbid-

den!

– Installation downstream of the protective

filter as per DIN EN 13443-1 and DIN

19628.

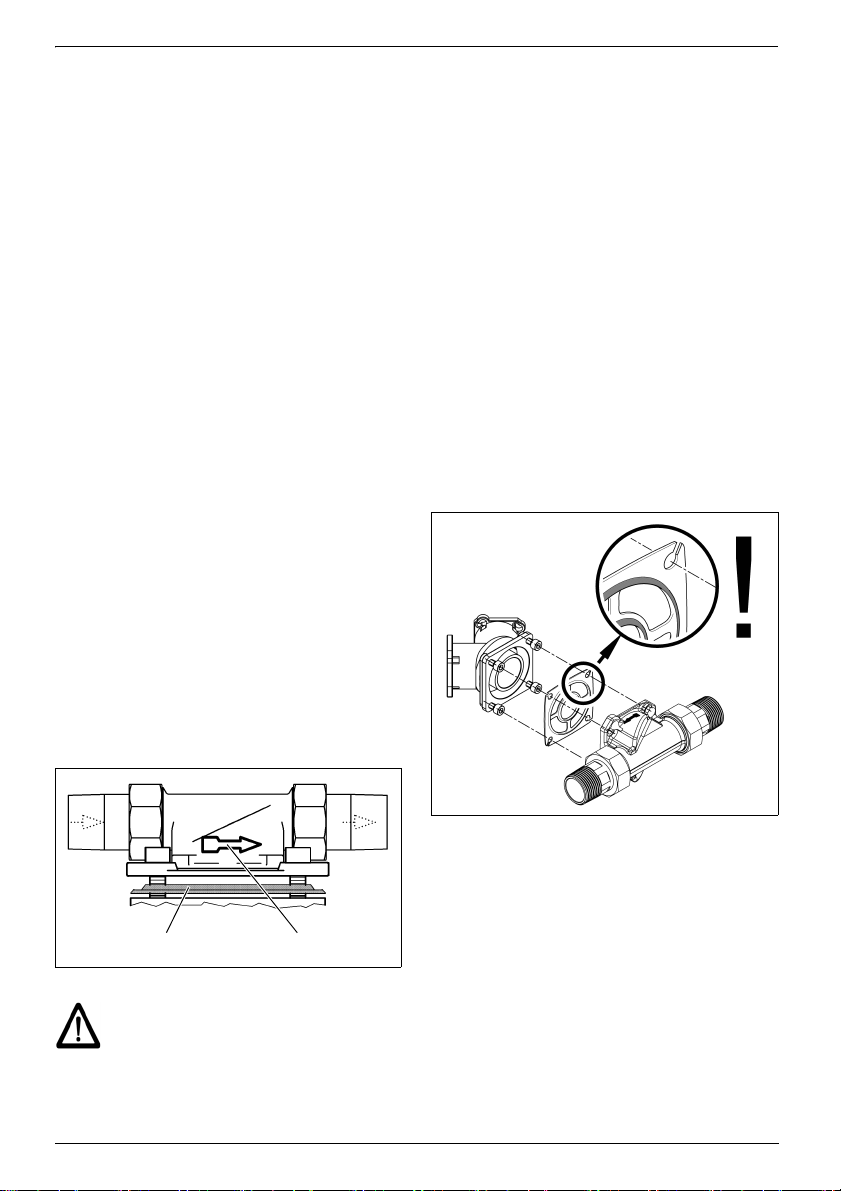

4.1.2 Installation position

4.1.3 Power supply

The mains voltage must not be interrupt-

ed (e.g. via a light switch).

If the water softening system does not have

a permanent power connection,

To ensure fault-free operation, ob-

serve the following requirements:

A permanent power connection (230

V, 50 Hz) must be available.

Always install the water softening

system in an upright position

(± 5°)! If this is not observed, in-

correct functioning may result.

A splash-proof socket, complying

with the legal regulations for wet are-

as, is required for the power supply

unit.