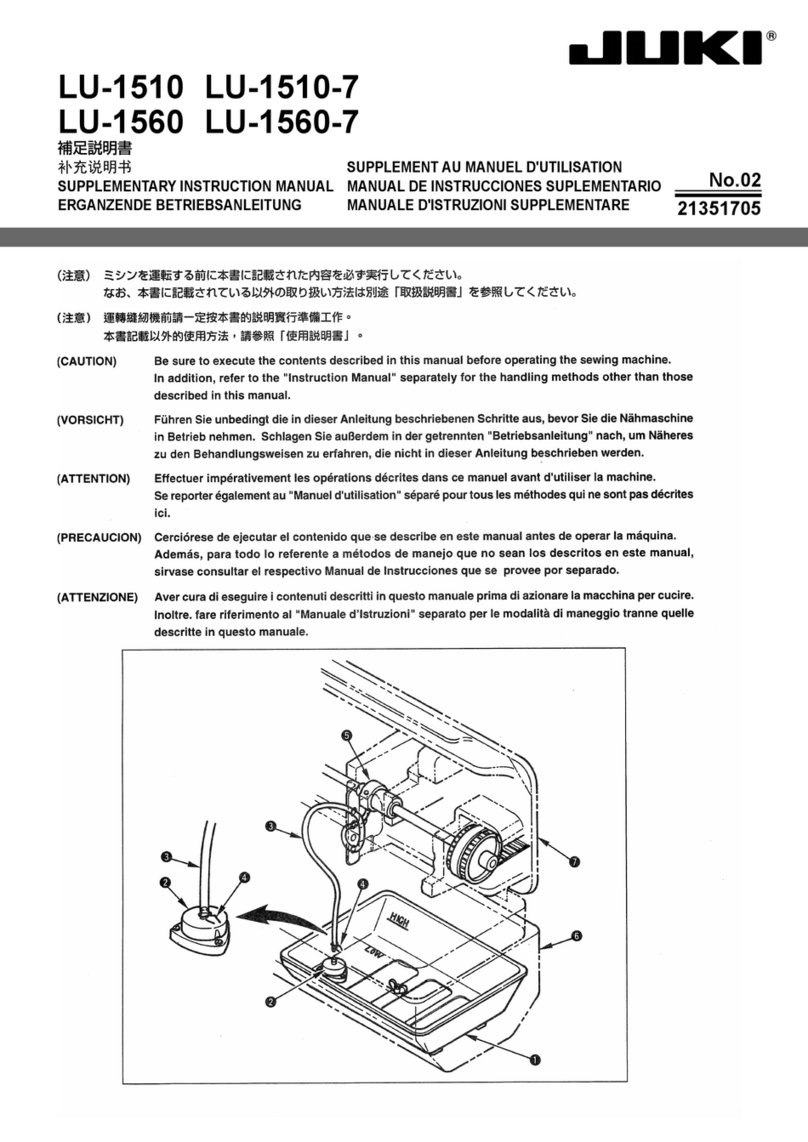

A wider sewing table is prepared for

large-sized garment bodies.

A wider sewing table is prepared for

large-sized garment bodies.

The operation panel is specifically

designed to facilitate easy operation.

The exclusive machine head

finishes beautiful seams.

Crease-folding unit helps produce

pockets of upgraded quality.

AVP-875A

The machine demonstrates improved

productivity.

The machine automatizes a series of pocket-setting

processes, concurrently folding and sewing sequential pocket

cloths in the production line, thereby resulting in substantial labor

savings. With its newly developed large-hooked zigzag-stitching

lockstitch machine head, the machine run at a maximum sewing

speed of 4,000rpm and executes all of its operations with split-

second response. The sum result: dramatically reduced cycle time

and increased productivity.

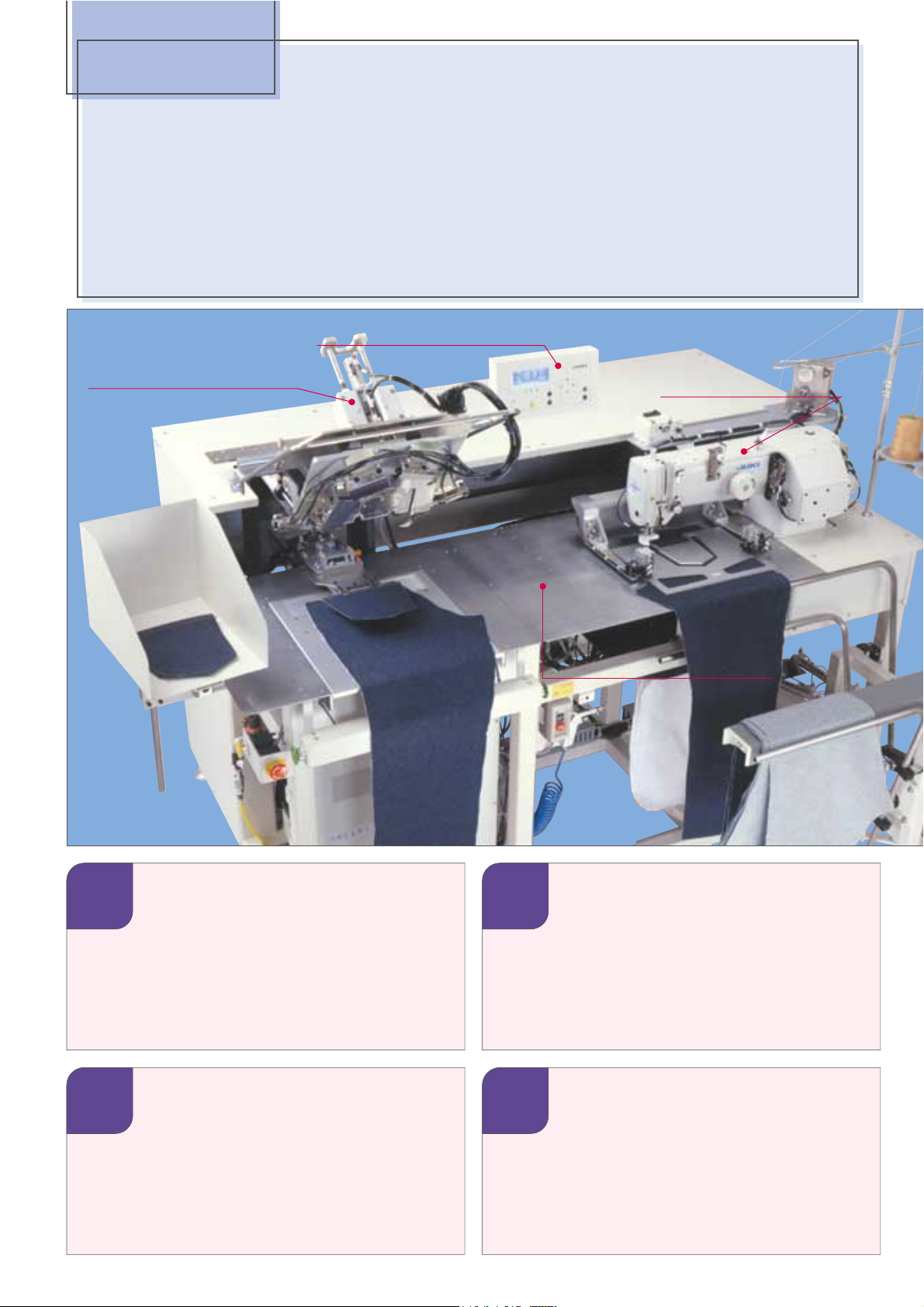

The machine folds pocket cloths

with beautiful, sharp creases and

absolutely no material slippage.

A pocket cloth is folded on the table surface and

properly tensed by a pocket style jig to create sharp creases

without material slippage or bulging. The pocket cloth is vertically

shifted and pulled to the suitable tautness for placement on the

garment body. This prevents the pocket cloth from slipping out of

the correct position and makes it easy to adjust folding timing. With

this pocket-folding and pocket-positioning mechanism, the machine

is widely adaptable to various materials.

The machine is ready for large

garment bodies.

The folding unit is sufficiently spaced from the machine

head. This means large garment bodies never interfere with each

other even when right and left garment bodies are alternately

processed on the machine. The machine widely adapts to

materials of various sizes and many different sewing specifications.

The machine achieves consistent

seam quality.

The work clamp plate clamps the pocket cloth at the

center of the sewing area so that the entire pocket cloth is pressed

down evenly, thereby preventing the cloth from flopping. In

addition, by installing JUKI's unique hook-driving-shaft offset

mechanism in the machine head, the machine produces beautiful

seams with consistency while preventing the stitch skipping or

thread breakage that is liable to occur when the needle throws to

the right and left.

12

45

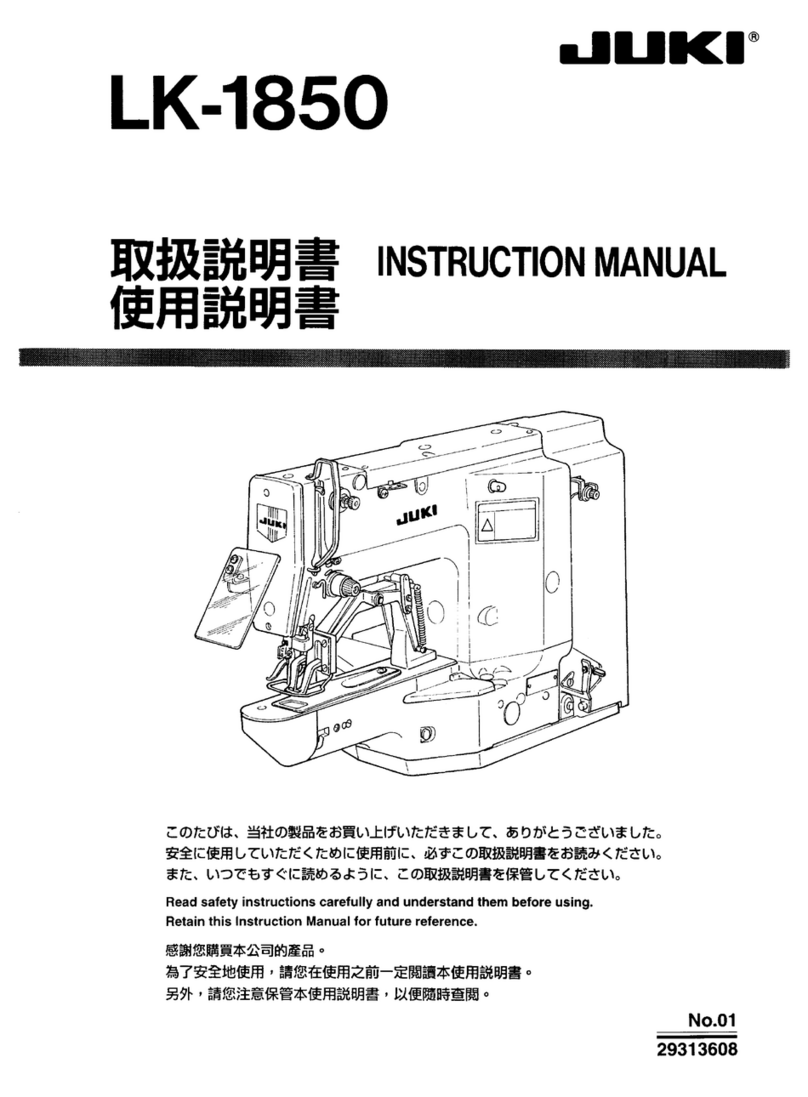

JUKI automatic pocket setter is a highly advanced machine that

automatically performs pocket setting procedures for jeans ranging

from folding the hip pocket piece, setting it onto the garment body,

sewing it, and stacking the finished product. The result is even more consistent quality and

higher productivity.

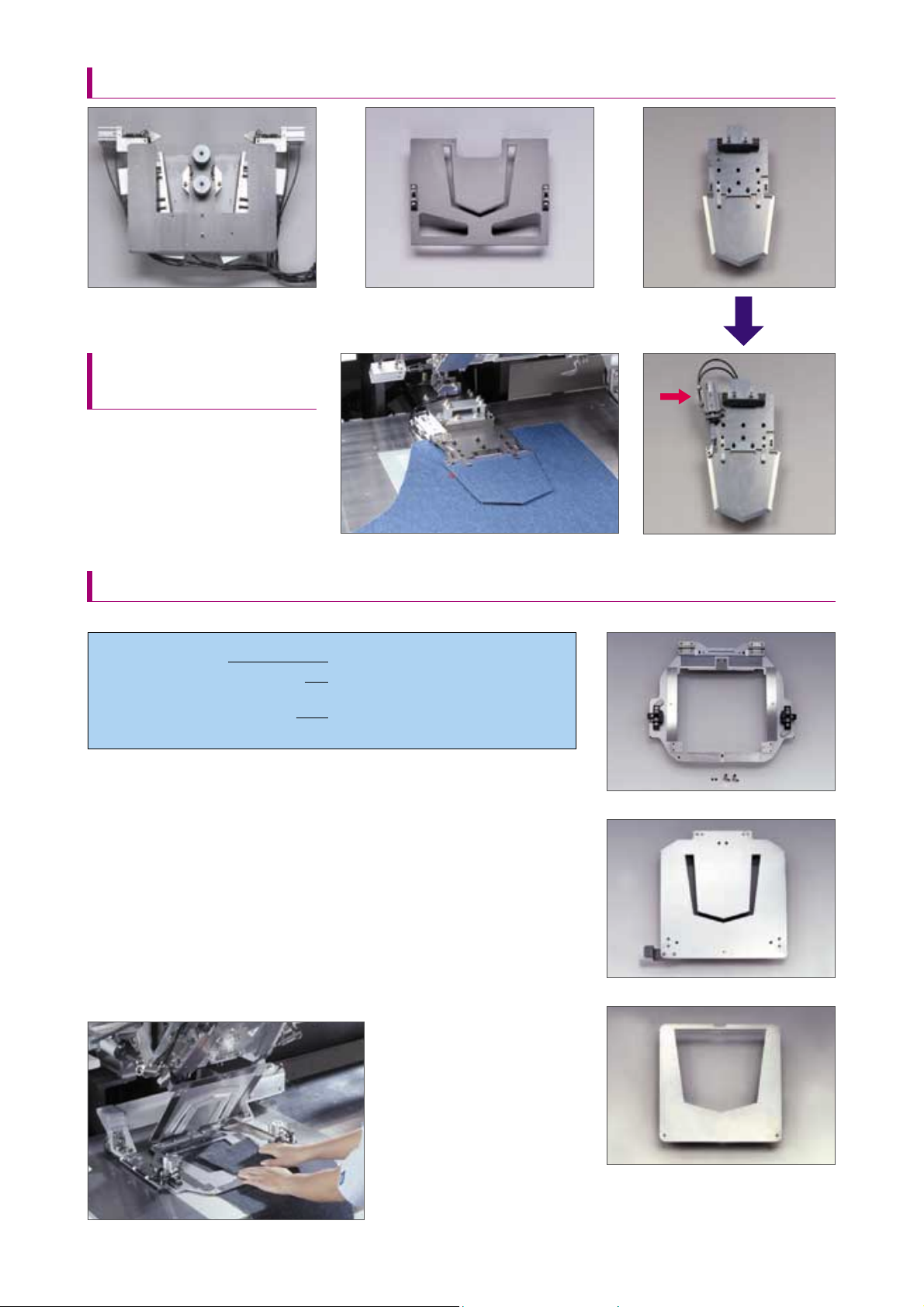

When the machine is equipped with the optional jig for a pre-folded pocket style, pocket

pieces folded in advance, upstream from the machine's standard pocket-setting functions,

can be sewn onto the garment body while disabling only the pocket-piece folding function.

This production style using the optional pocket style jig makes it possible to apply the

machine for the production of various products in small lots at a reduced cost.

The machine can be used in two different ways, i.e., as a regular pocket setter when the production

lot is large, or as a pre-folded pocket setter when the lot is small. In this way, the AVP-875 offers

increased availability.

AVP-875

AVP-875