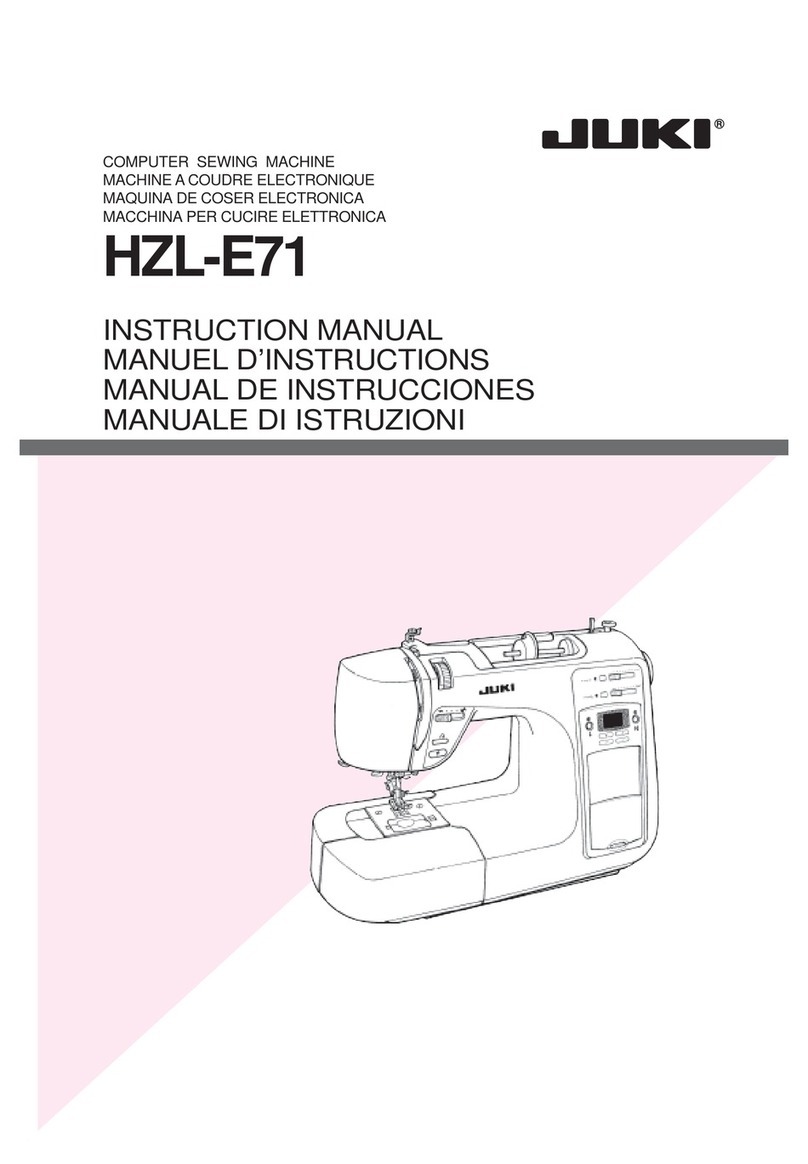

Sewing product

Feed

Sewing product

Walking

foot

Presser

foot

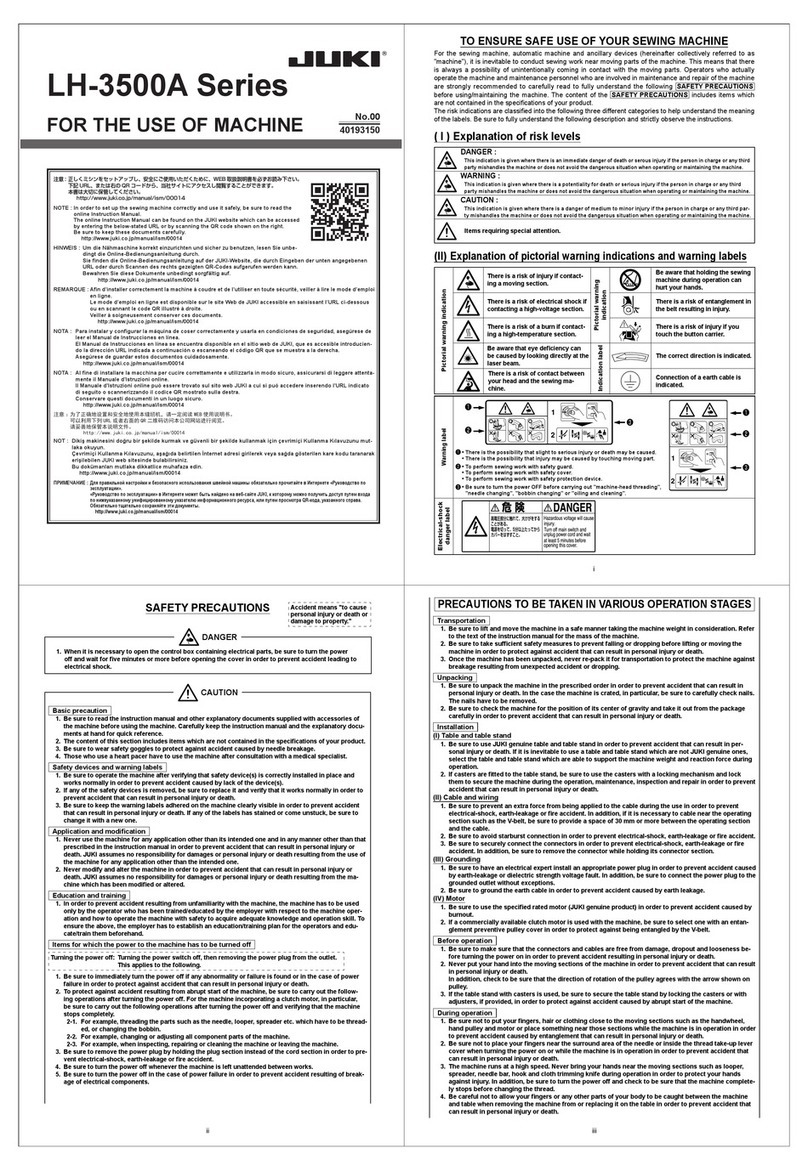

Comparison of the remaining thread length (with reverse stitching)

LU-1520N-7

Conventional machine

Right side Wrong side Right side Wrong side

End of sewing

Beginning

The remaining length of thread at the end of sewing

is substantially shortened to approximately 5mm.

The machine cuts thread as thick as #5 without fail.

Even if the needle thread is clamped under the

presser foot or walking foot, the machine draws the

needle thread onto the underside of the material

without fail, leaving no exposed thread on the right

side. The needle thread drawn onto the underside of

the material can be sewn under the seam.

The end-of-sewing thread is kept in the seam

allowance both at the beginning and end of sewing

and does not jut out from the material edge.

This function eliminates the need for thread snipping.

The operator is able to concentrate on sewing work

without having to perform thread snipping work,

thereby dramatically increasing productivity.

The frequency of scissor use by the operator is

significantly reduced, thereby preventing accidents

in which the scissors damage the material.

Conventional machines

Rectangular feed Alternating vertical

movement mechanism

•Compared with the elliptical feed, the

rectangular feed helps reduce gathered

stitches.

•The ratio of alternate vertical movement

remains unchanged even when the

material thickness changes.

The newly developed mode of highly rigid rectangular feed

guarantees outstanding feed performance. In addition, the ratio

between the alternating vertical movements of the walking foot

and presser foot remains unchanged even when the material

thickness changes. With this feature, the machine sews multi-

layered parts of the material consistently and without stitch

gathering.

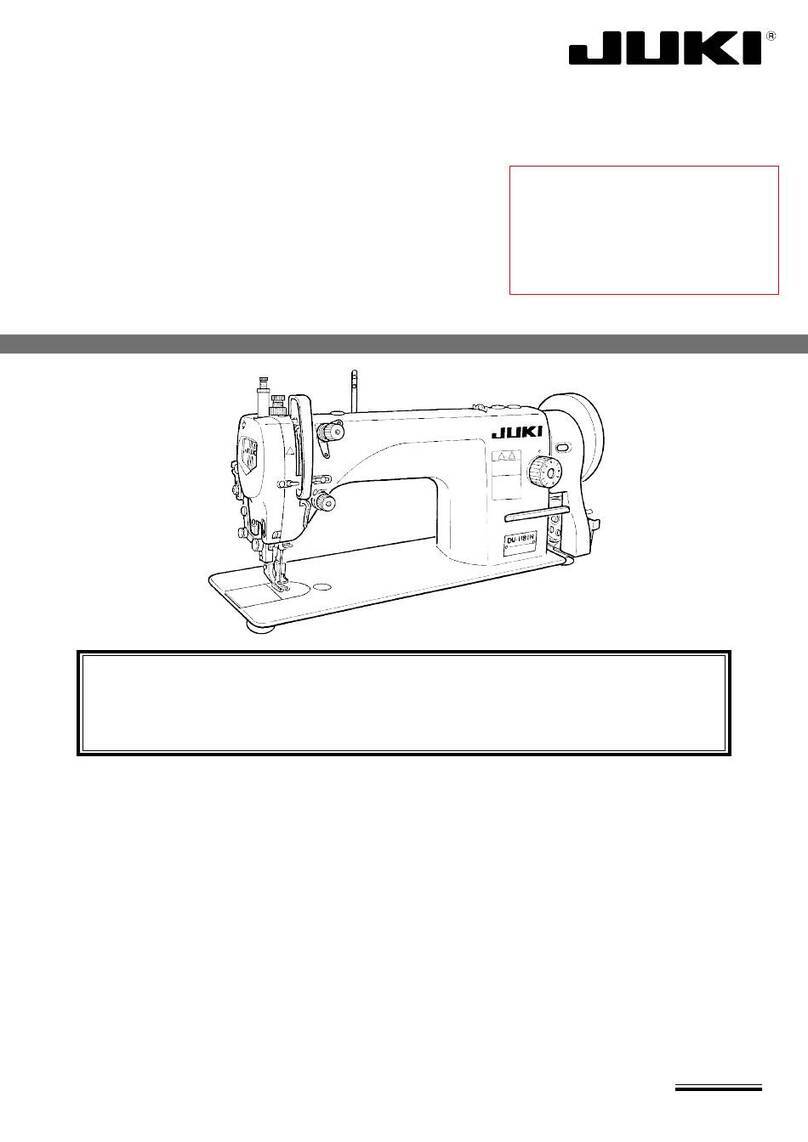

The vertical stroke of the presser foot and walking foot (amount of

alternating vertical movement) can be easily changed with the

large dial mounted on the top of the machine head. The sewing

speed is automatically regulated based on the vertical stroke

setting.

This ensures ideal sewing conditions at all times.

The machine is equipped as standard with a mechanism to correct

uneven material feed by making-micro adjustments to the bottom-

feed.

Thread snipping is no longer required at the beginning and end of sewing.Thread snipping is no longer required at the beginning and end of sewing.

Consistent seam quality.Consistent seam quality.

Thread snipping is no longer required at the beginning

and end of sewing. This is a high-performance machine

that is ideally suited to the sewing of car seats.

Thread snipping is no longer required at the beginning

and end of sewing. This is a high-performance machine

that is ideally suited to the sewing of car seats.

Thread snipping work that has traditionally been required by

conventional machines can now be virtually eliminated, thereby

drastically increasing productivity.

In addition, jut-out thread problems or accidents in which the

material is damaged by scissors during sewing can be prevented.

The machine contributes to reduced cost and upgraded quality in the

sewing of car seats.

Thread snipping work that has traditionally been required by

conventional machines can now be virtually eliminated, thereby

drastically increasing productivity.

In addition, jut-out thread problems or accidents in which the

material is damaged by scissors during sewing can be prevented.

The machine contributes to reduced cost and upgraded quality in the

sewing of car seats.

LU-1520N-7, LU-1521N-7

●

●

●

●●

●