– 1 –

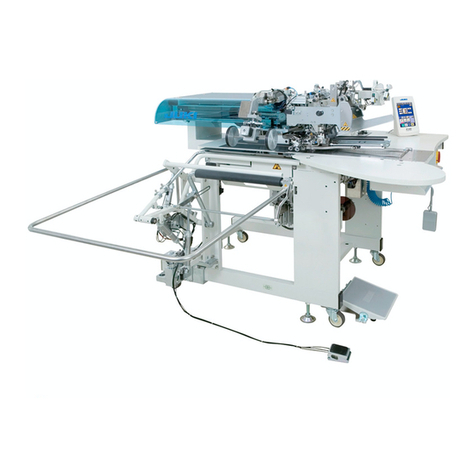

1. SPECIFICATIONS

No. Item Application

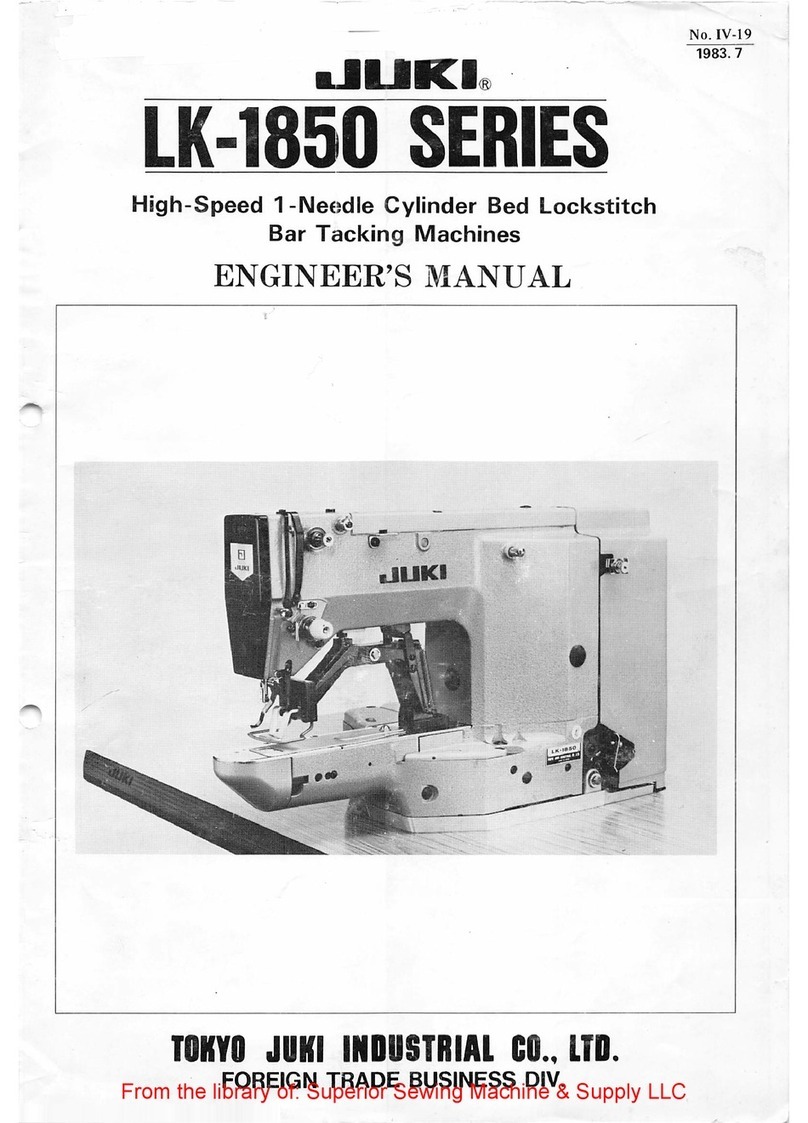

1 Model LS-2342S LS-2342S-7

2 Model name Cylinder-bed, 1-needle, unison-feed,

lockstitch machine

(Standard type)

Cylinder-bed, 1-needle, unison-feed,

lockstitch machine with automatic thread

trimmer (Standard type)

3 Application Medium- to heavy-weight materials, car seat, furniture

4 Sewing speed Max. 2,500 sti/min (See "6. SEWING SPEED TABLE" p.27.) *1

5 Needle SCHMETZ 134-35

(Nm 100 to Nm 180, Standard : Nm 140)

6 Applicable thread size for sewing #40 to #5

(US : #33 to #138, Europe : 90/3 to 20/3)

#30 to #5

(US : #46 to #138, Europe : 60/3 to 20/3)

7 Applicable thread size to be cut #30 to #5

(US : #46 to #138, Europe : 60/3 to 20/3)

8 Stitch length Max. 9 mm (forward/reverse feed)

9 Stitch length dial 1-pitch dial 2-pitch dial

10 Presser foot lift Hand lifter : 10 mm, Automatic presser foot lifter : 20 mm

11 Stitch length adjusting mechanism By dial

12 Reverse stitch adjusting method By lever Air cylinder type

(with touch-back switch)

13 Thread take-up Link type

14 Needle bar stroke 40 mm

15 Amount of the alternate vertical

movement

1 mm to 9 mm (Alternate vertical dial adjustment type)

16 Hook Full-rotary vertical-axis 1.6-fold hook (Latch type)

17 Feed mechanism Elliptical feed

18 Top and bottom feed actuation

mechanism

Timing belt

19 Thread trimming method Cam-driven scissors type

20 Lubrication Concentrated tank type oil wick lubrication (partially by manual)

21 Lubricating oil JUKI New Defrix Oil No. 2 (equivalent to ISO standard VG32)

22 Tube diameter 72 mm

23 Space under the arm 347 mm × 127 mm

24 Hand wheel size Outer diameter : ø123 mm

25 Motor/Control box SC-922B

26 Machine head weight 61 kg 63 kg

27 Rated power consumption 310VA

28 Noise - Equivalent continuous emission sound

pressure level (LpA) at the workstation:

A-weighted value of 83.0 dB; (Includes

KpA = 2.5 dB); according to ISO 10821-

C.6.3 - ISO 11204 GR2 at 2,500 sti/min.

- Sound power level (LWA);

A-weighted value of 89.5 dB; (Includes

KWA = 2.5 dB); according to ISO 10821-

C.6.3 - ISO 3745 GR2 at 2,500 sti/min.

- Equivalent continuous emission sound

pressure level (LpA) at the workstation:

A-weighted value of 77.5 dB; (Includes

KpA = 2.5 dB); according to ISO 10821-

C.6.3 - ISO 11204 GR2 at 2,500 sti/min.

*1 The speed setting according to the amount of the alternating vertical movement of the walking foot and presser

foot is automatically carried out.