JUKI LZ-271 User manual

Other JUKI Sewing Machine manuals

JUKI

JUKI HZL-E70 User manual

JUKI

JUKI MO-6804S User manual

JUKI

JUKI AMS-210DHL-6100 User manual

JUKI

JUKI LH-3500A series User manual

JUKI

JUKI SC-922 User manual

JUKI

JUKI TL-98Q User manual

JUKI

JUKI DNU-1541-7 User manual

JUKI

JUKI SC-920 Quick start guide

JUKI

JUKI DDL-9000A User manual

JUKI

JUKI MO-6000G Series Quick start guide

JUKI

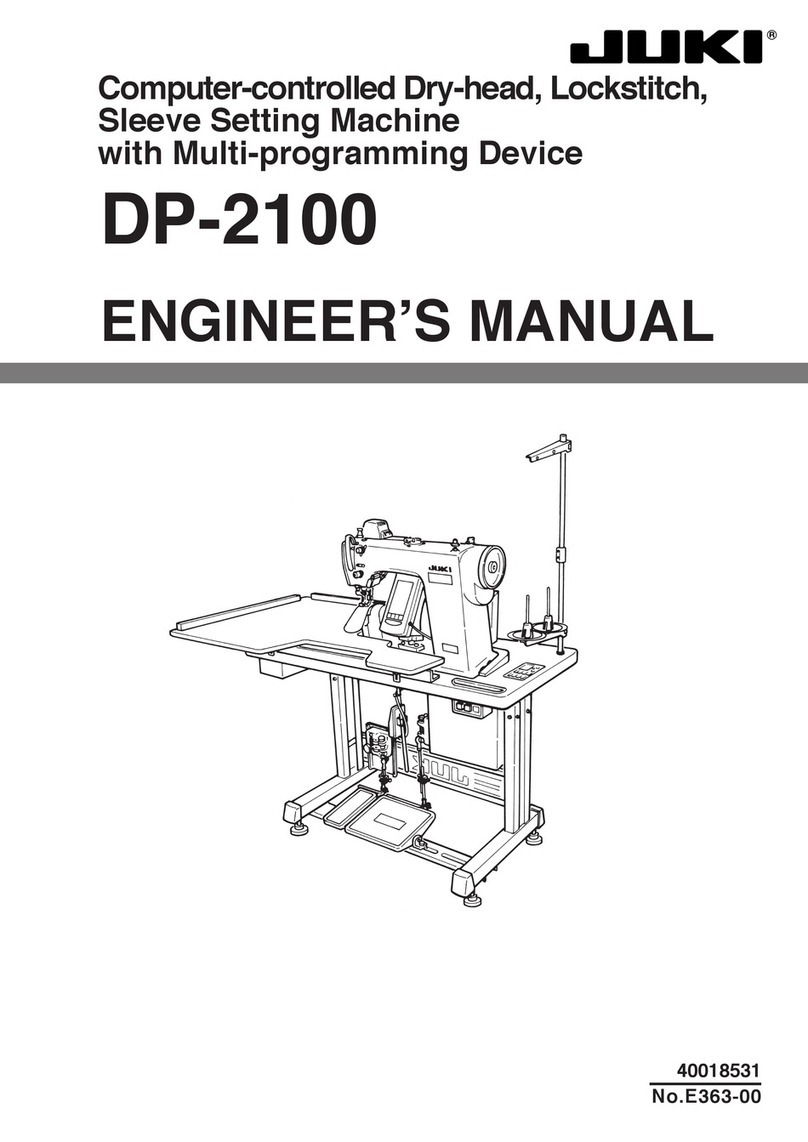

JUKI DP-2100 Quick start guide

JUKI

JUKI LU-2860V-7 User manual

JUKI

JUKI MO-6804D User manual

JUKI

JUKI LG-158 User manual

JUKI

JUKI APW-895NE User manual

JUKI

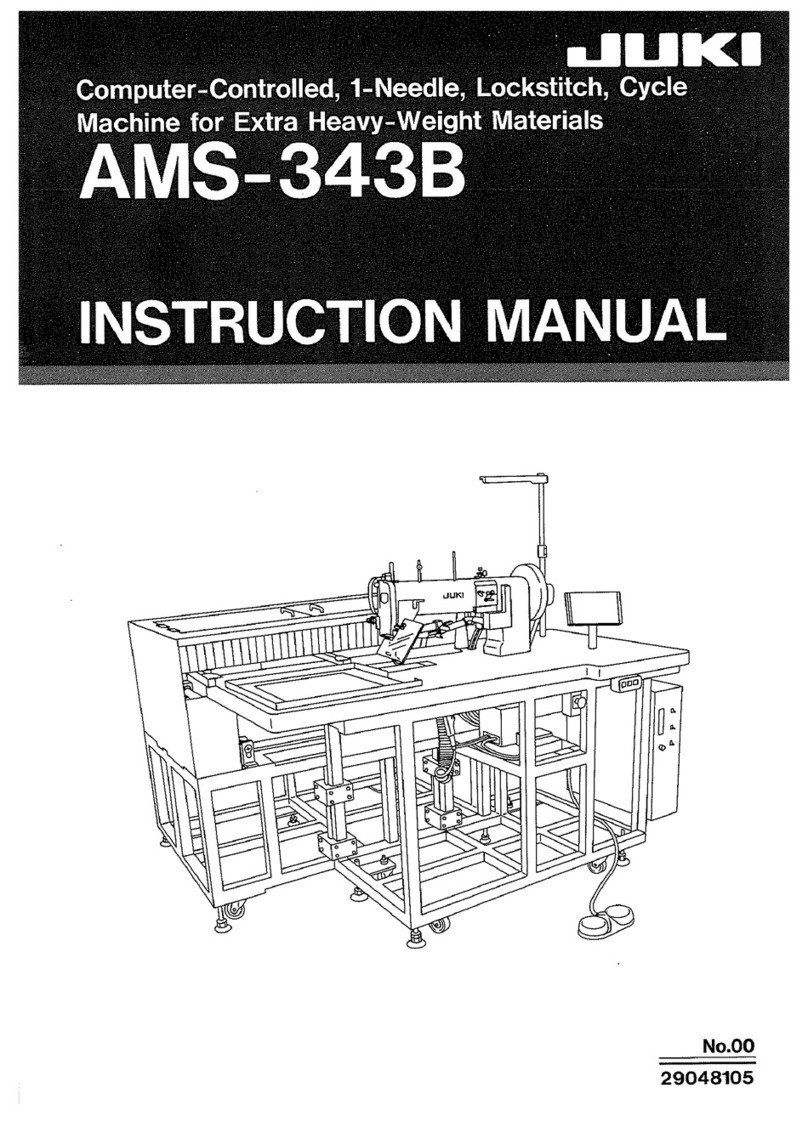

JUKI AMS-343B User manual

JUKI

JUKI MB-373N/BR10 User manual

JUKI

JUKI MF-7200D/UT42 User manual

JUKI

JUKI MO-623N User manual

JUKI

JUKI HZL-30Z User manual