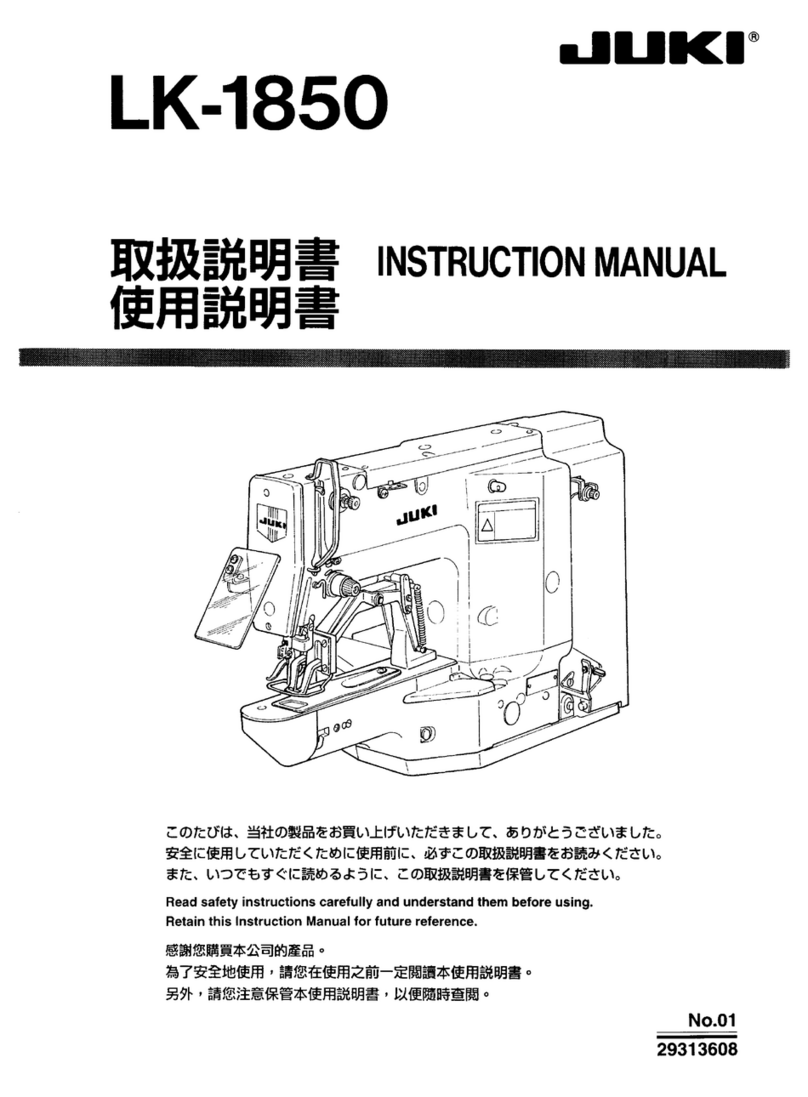

i

CONTENTS

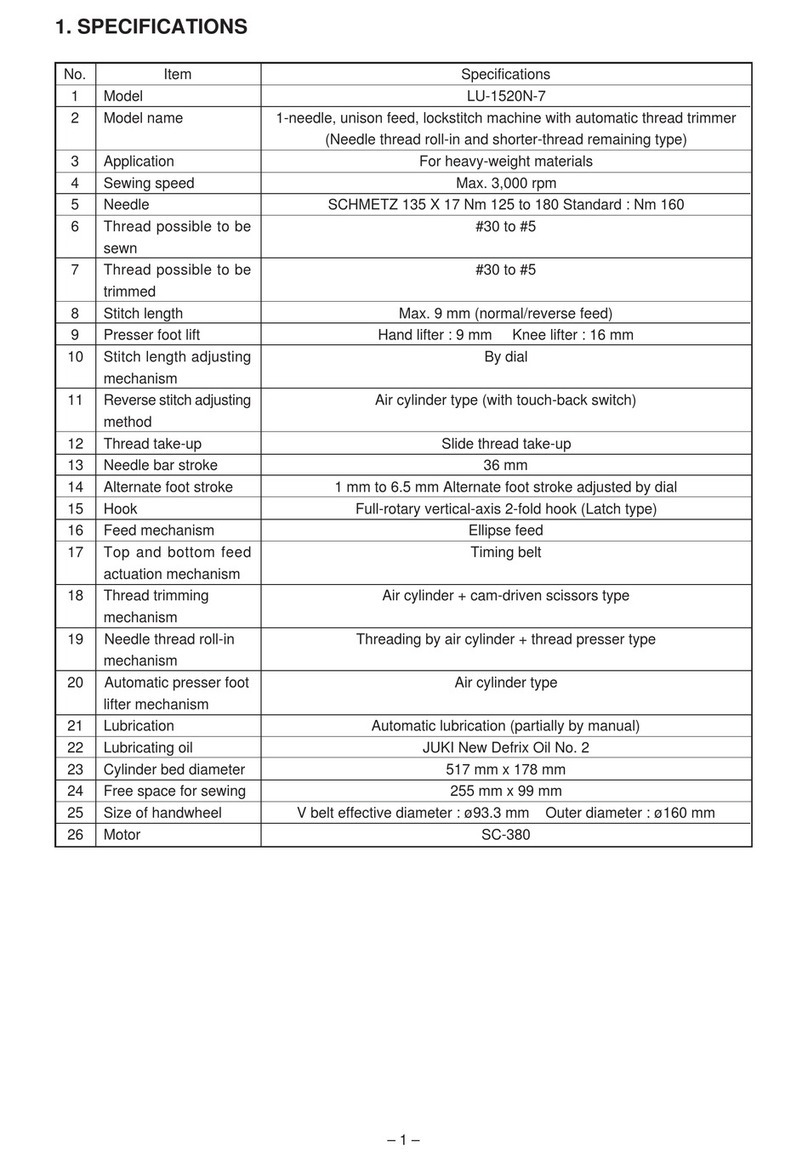

1. SPECIFICATIONS .............................................................................................1

2. CONFIGURATION .............................................................................................2

3. INSTALLATION..................................................................................................3

3-1. Installing the operation panel........................................................................................3

3-2. Installing the power switch and the button switch......................................................4

3-3. Installing the air hose.....................................................................................................6

3-4. Installing the thread stand ............................................................................................7

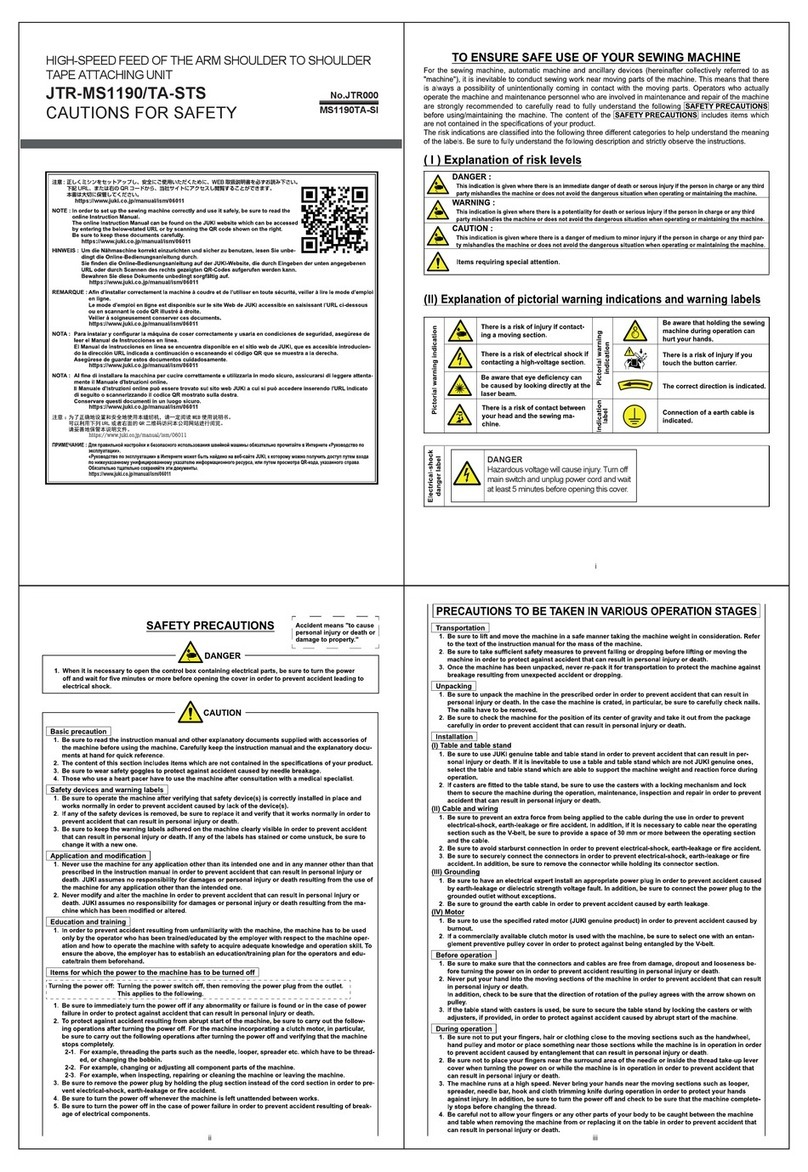

3-5. Cautions for the compressed air supply (source of supply air) facility ....................8

3-6. Installing the bobbin winder device..............................................................................9

3-7. Precautions for installation of the machine ...............................................................11

4. PREPARATION OF THE SEWING MACHINE................................................12

4-1. Lubricating method and check of the oil quantity.....................................................12

4-2. Attaching the needle.....................................................................................................13

4-3. Threading the machine head .......................................................................................14

4-4. Bobbin replacement procedure...................................................................................15

4-5. Adjusting the thread tension .......................................................................................16

4-6. Adjusting the thread take-up spring and the thread breakage detector plate........17

4-7. Adjusting the thread take-up stroke............................................................................17

4-8. Needle-to-hook relationship ........................................................................................18

4-9. Adjusting the position of the thread trimmer.............................................................20

4-10. How to check the amount of oil in the hook...............................................................22

4-11. Adjusting the amount of oil in the hook .....................................................................23

4-12. Adjusting the needle hole in the throat plate and the needle...................................24

4-13. Setting the mechanical origin......................................................................................25

4-14. Adjusting the disk presser pressure...........................................................................26

4-15. Adjusting the thread end position at the beginning of sewing ................................27

4-16. Adjusting the intermediate presser stroke.................................................................28

4-17. Adjusting the needle thread air blower.......................................................................29

4-18. Making a template.........................................................................................................30

4-19. Preparation for sewing.................................................................................................32

4-20. Conguration of the operation panel..........................................................................34

4-21. Maintenance mode........................................................................................................36

4-22. List of parameters.........................................................................................................37

4-23. List of error codes ........................................................................................................43

5. MAINTENANCE OF SAWING MACHINE .......................................................59

5-1. Troubles and corrective measures (Sewing conditions) ..........................................61

5-2. Disposal of batteries.....................................................................................................63

5-3. Draining waste oil .........................................................................................................63