(4)

Unless

the

bottom

surface

of the

presscr

foot ® and the

upper

surface

of the

throat

plate are

snuggly

contacting each other when the feed dog is lowered, the stitches may

become curved and the chain-off thread stitching of double chain stitch can not be

performed

well.

Loosen

the

presser

foot

hinge

screw © and adjust so that the bottom

surface

of the

presser

foot ® drops little to right

when

the

presser

foot is

raised

and

when the

presser

foot is lowered, the bottom

surface

snuggly

contacts the throat plate

surface. (In case of MO-816)

(Note)

*

When

sewmg

light

weight

materials,

if

the

pressing

pressure

is

too

strong

or

the

protrusion

amount

of

the

feed

dog

is

too

great,

shrink

stitch-

irig

or

damage

to

the

sewing

cloth

may

result.

On

the

contrary,

if

the

pressure

is

too

weak

or

the

protrusion

of

the

feed

dog

is

too

small,

pitch

flaw

or

contracted

stitches

might

result.

Be

sure

to

make

correct

adjustment.

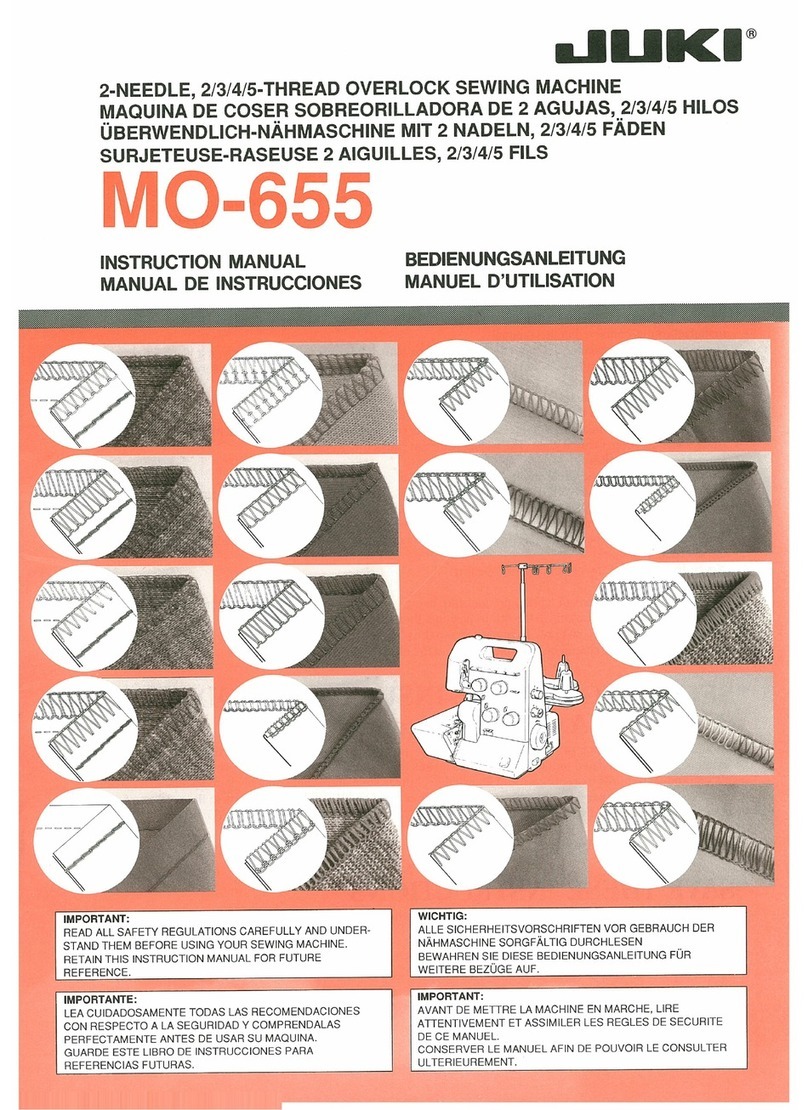

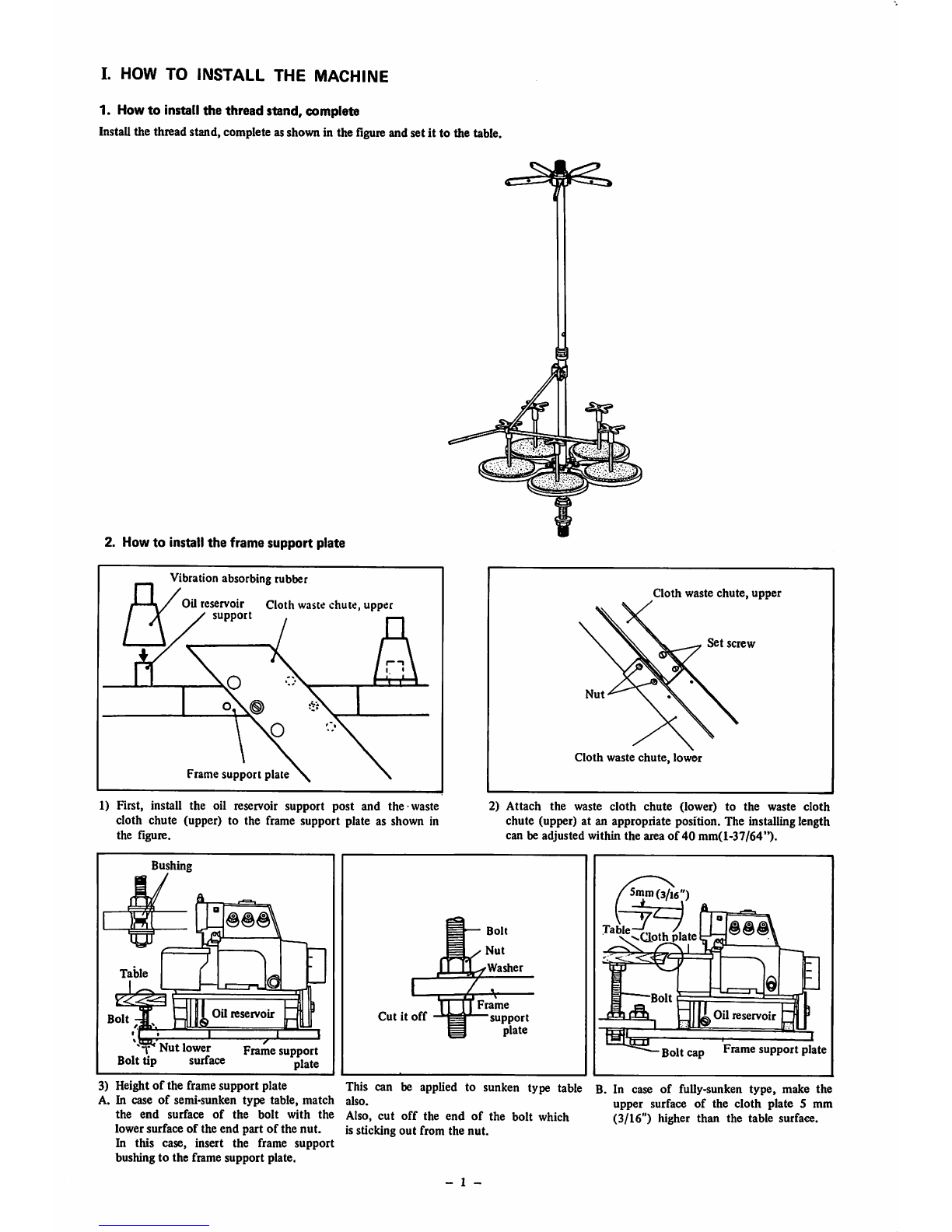

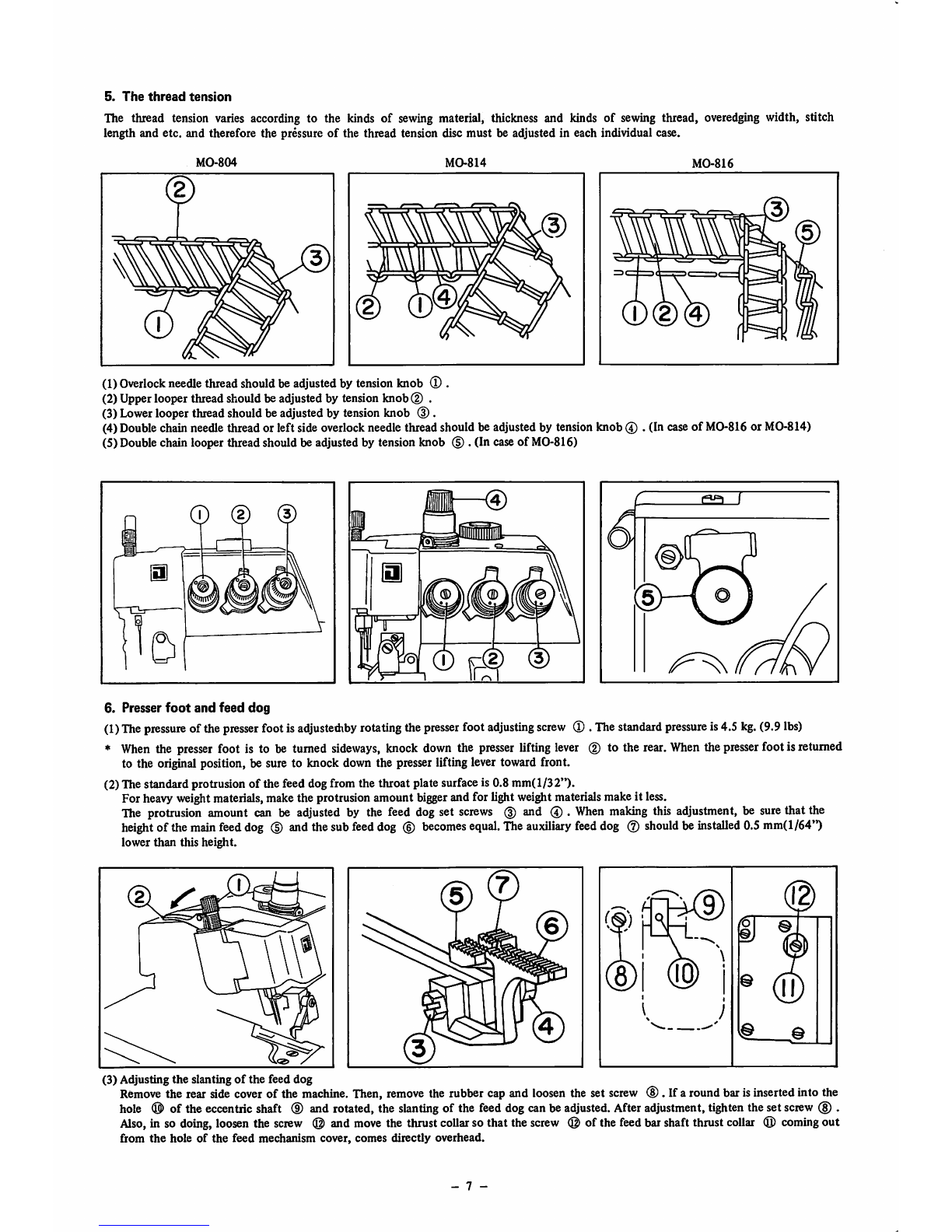

7. Adjusting

the

stitch length

The stitch length can be adjusted by changing the eccentric amount of the feed cam.

\i

/

csT

Indicating

(1)As you keep

pushing

the push button

(T)

with your

finger,

rotate

the

pulley

toward

the desired direction.

You

will

hear

a

"click"

sound and the push

button

will

enter

deep inside.

(2) As you keep pressing the

button,

match the stitch length which

is carved in the pulley with the indicating point of the frame.

(3) The figures carved in the pulley indicate the stitch length.

If the figure

"3"

of the pulley is matched with the indicating

point of the frame, the stitch length becomes approximately

3

mm.

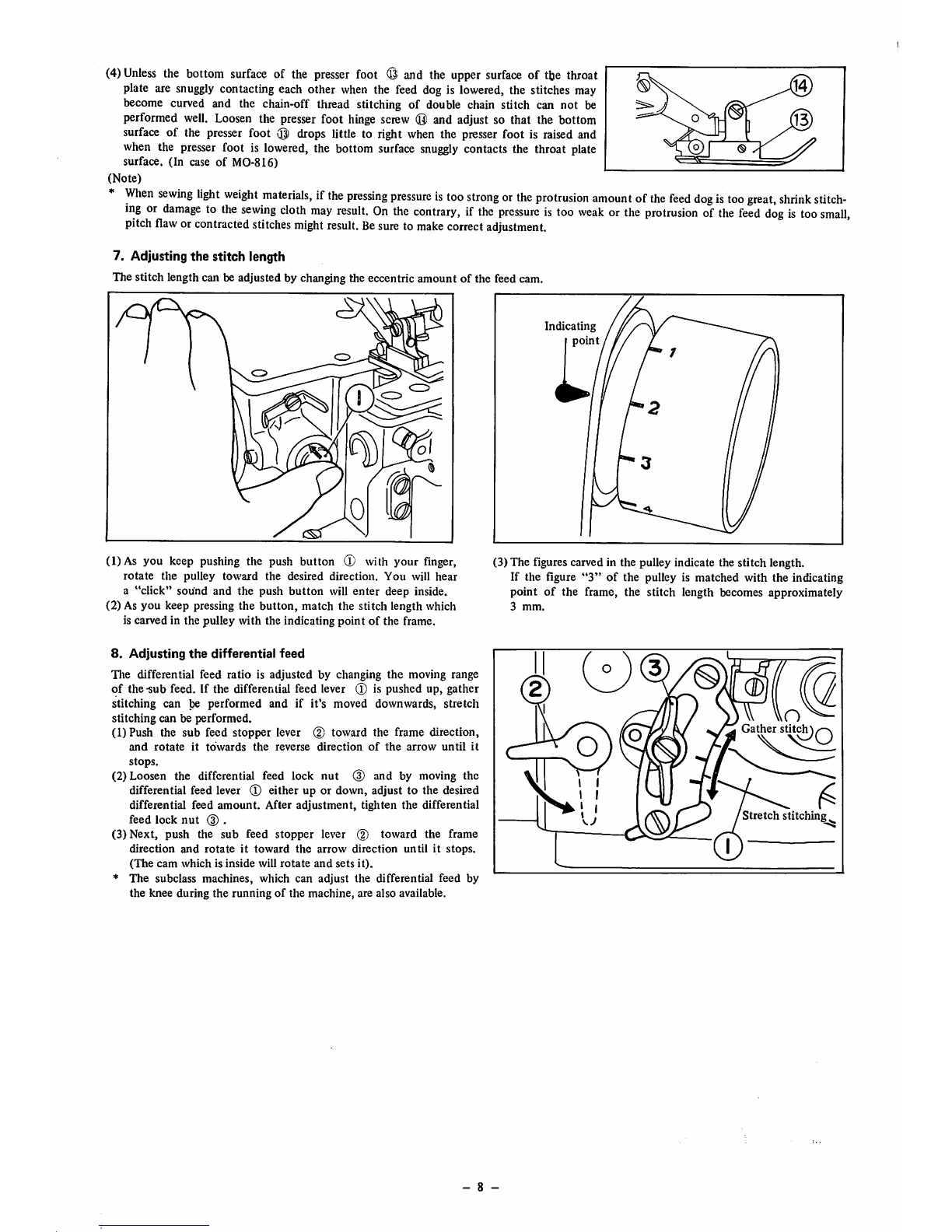

8.

Adjusting

the

differential

feed

Tlie differential feed

ratio

is

adjusted

by changing

the

moving range

of the-sub feed. If the differential feed lever ® is pushed up, gather

stitching

can be

performed

and

if

it's

moved

downwards,

stretch

stitching

can be

performed.

(1)Push

the

sub

feed

stopper

lever (2)

toward

the frame direction,

and

rotate

it

towards

the

reverse

direction

of

the

arrow

until

it

stops.

(2) Loosen the differential feed lock

nut

(3) and by moving the

differential feed lever ® either up or down, adjust to the desired

differential feed

amount.

After

adjustment,

tighten

the differential

feed

lock

nut

(3).

(3)

Next,

push

the

sub

feed

stopper

lever (2)

toward

the

frame

direction

and

rotate

it

toward

the

arrow

direction

until

it

stops.

(The

cam

which

is

inside

will

rotate

and

sets

it).

*

The

subclass machines, which can adjust

the

differential feed by

the knee during the running of the machine, are also available.

- 8 -

(D

n

Gather

stitcl^^^

Stretch

stitching