LK-1900A-SS (Table stand is optionally available.)

LK-1900A SERIES

LK-1900A SERIES

The machine runs at 3,000rpm, faster than

any other sewing machine ever made.

The proven computer-controlled

bartacking machine

has been dramatically

evolved to be an

easier-to-use machine.

The machine runs at 3,000rpm, faster than

any other sewing machine ever made.

The proven computer-controlled

bartacking machine

has been dramatically

evolved to be an

easier-to-use machine.

The machine runs at 3,000rpm, faster than

any other sewing machine ever made.

The proven computer-controlled

bartacking machine

has been dramatically

evolved to be an

easier-to-use machine.

Active tension

The machine runs at 3,000rpm, faster than any other

sewing machine ever made.

In addition to the high-speed sewing performance,

the machine's starting, stopping, thread-trimming and

automatic presser lifting speeds have been increased

to significantly shorten total cycle time (reduced

approximately 30% compared to our predecessor model:

For 42-stitch large bartacks).

Higher productivity.

Since the machine is provided with an active tension mechanism, it is able to set a

needle thread tension that matches various sewing conditions (such as thread,

material and sewing speed) on the operation panel, store the data in memory

and reproduce it.

The needle thread tension can be separated according to stitching type or

portion of a seam, such as the beginning part of the seam, base stitched part,

zigzag stitched part and end of the seam (fastening stitch).

When the operation panel IP-410B is used in combination with the active tension,

the needle thread tension can be set on a stitch-by-stitch basis. This helps

eliminate undesired thread tension variations at a multi-layered part of a material

or with sewing direction, thereby contributing to upgraded seam quality.

The machine is provided as standard with the active

tension (electronic thread tension control mechanism).

Thanks to our advanced dry-head technology, the frame

(needle bar and thread take-up) no longer requires

lubrication. This prevents the material from being stained

with lubricating oil.

Just a small quantity of just clean oil is supplied from

the oil tank to the hook.

Oil stains are eliminated.Wider sewing area and

many different sewing patterns.

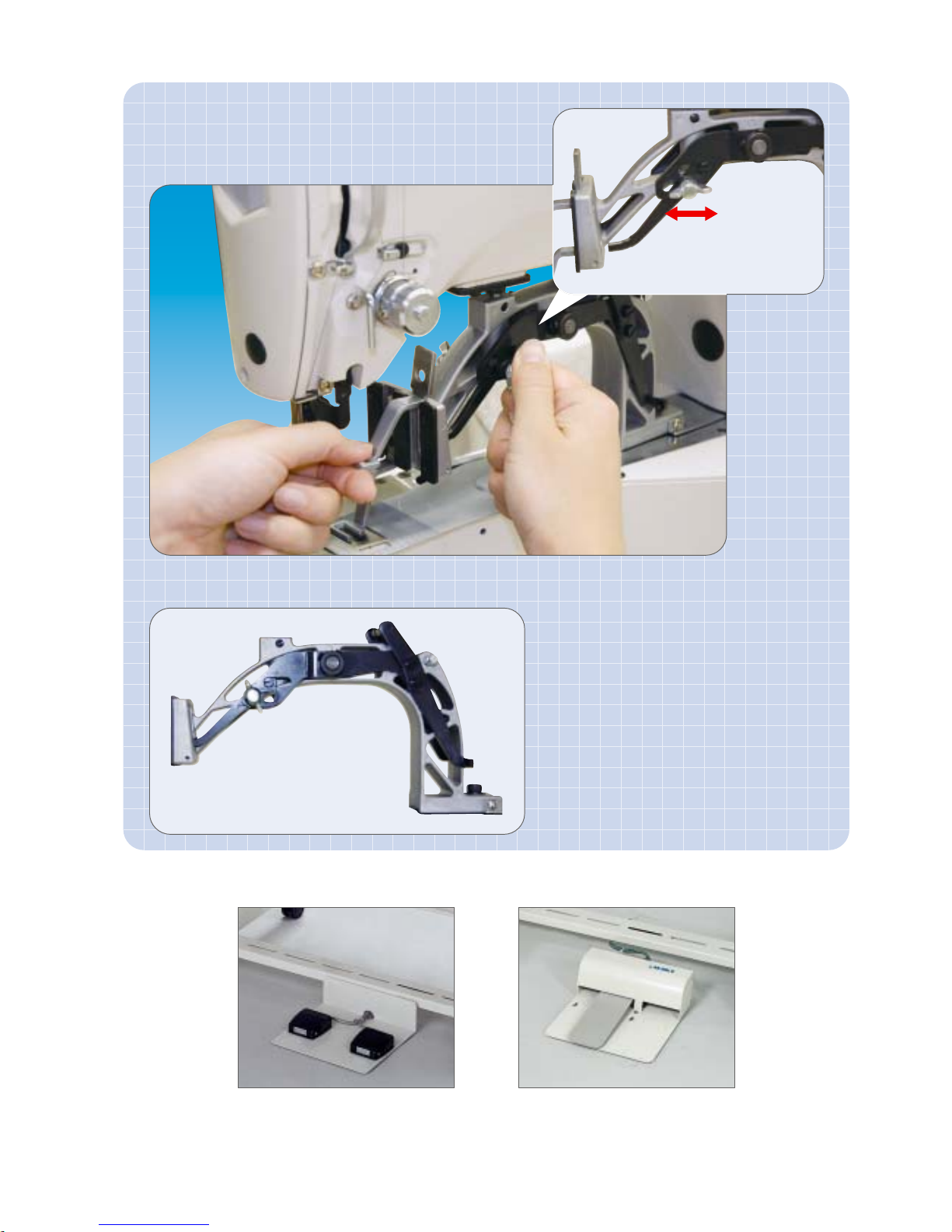

The machine comes with a newly developed needle

thread grasping mechanism. The mechanism prevents

thread from slipping off from the needle eyelet at the

beginning of sewing, from tangling on the wrong side

of the material and also being stained during sewing.

The thread trimming mechanism has been further

improved to shorten the length of thread remaining

on the wrong side of the material after thread trimming.

Excellent seam quality.

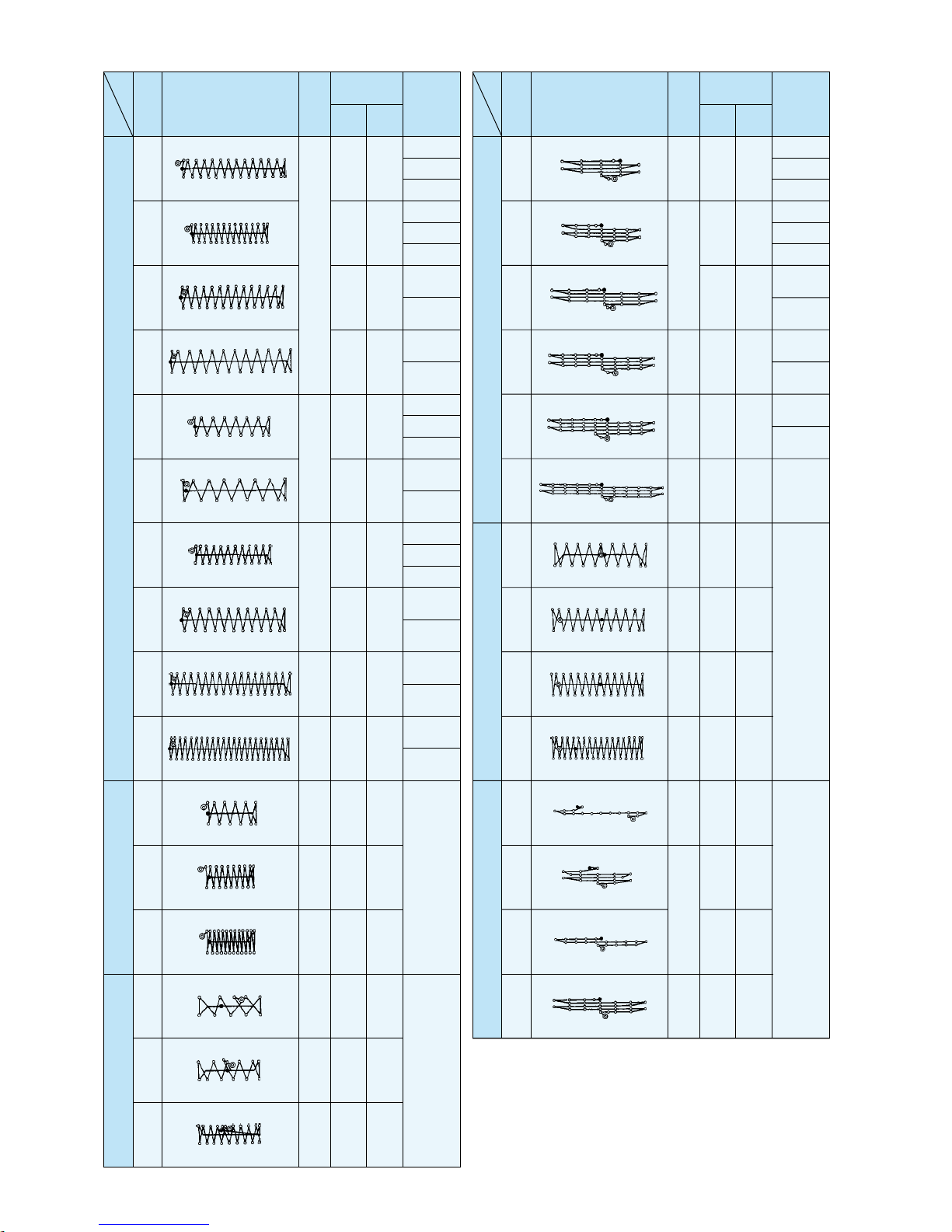

With its 30mm (length) by 40mm (width) sewing area,

the machine can sew many different shapes of bartacks.

The machine is provided as standard with as many as

50 different types of sewing patterns including semilunar

bartacking, round bartacking, radial tacking as well as

conventional bartacks.

The LK-1900A is also able to sew bartacks using the

same data used for the LK-1900 (EP-ROM).