– 2 –

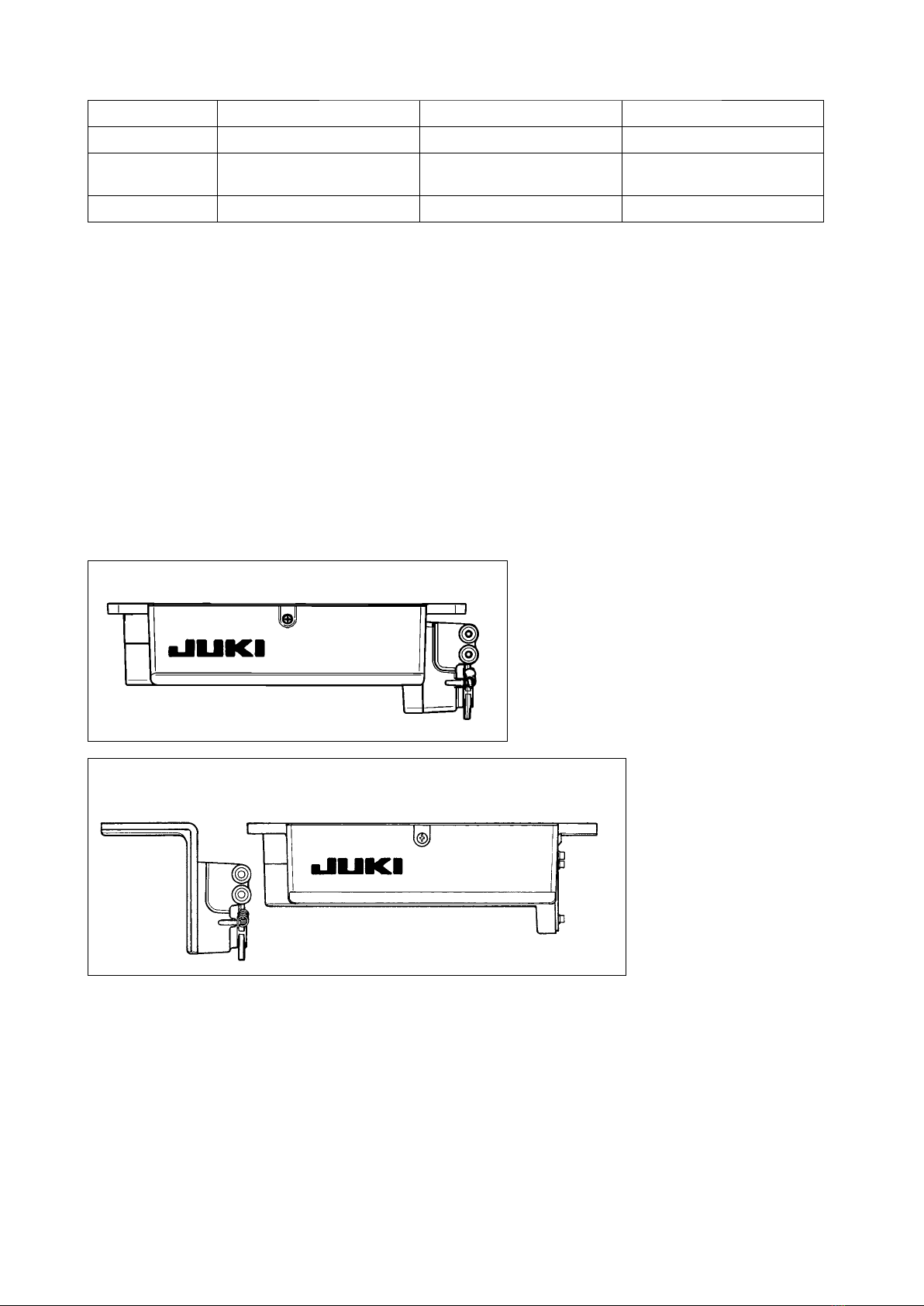

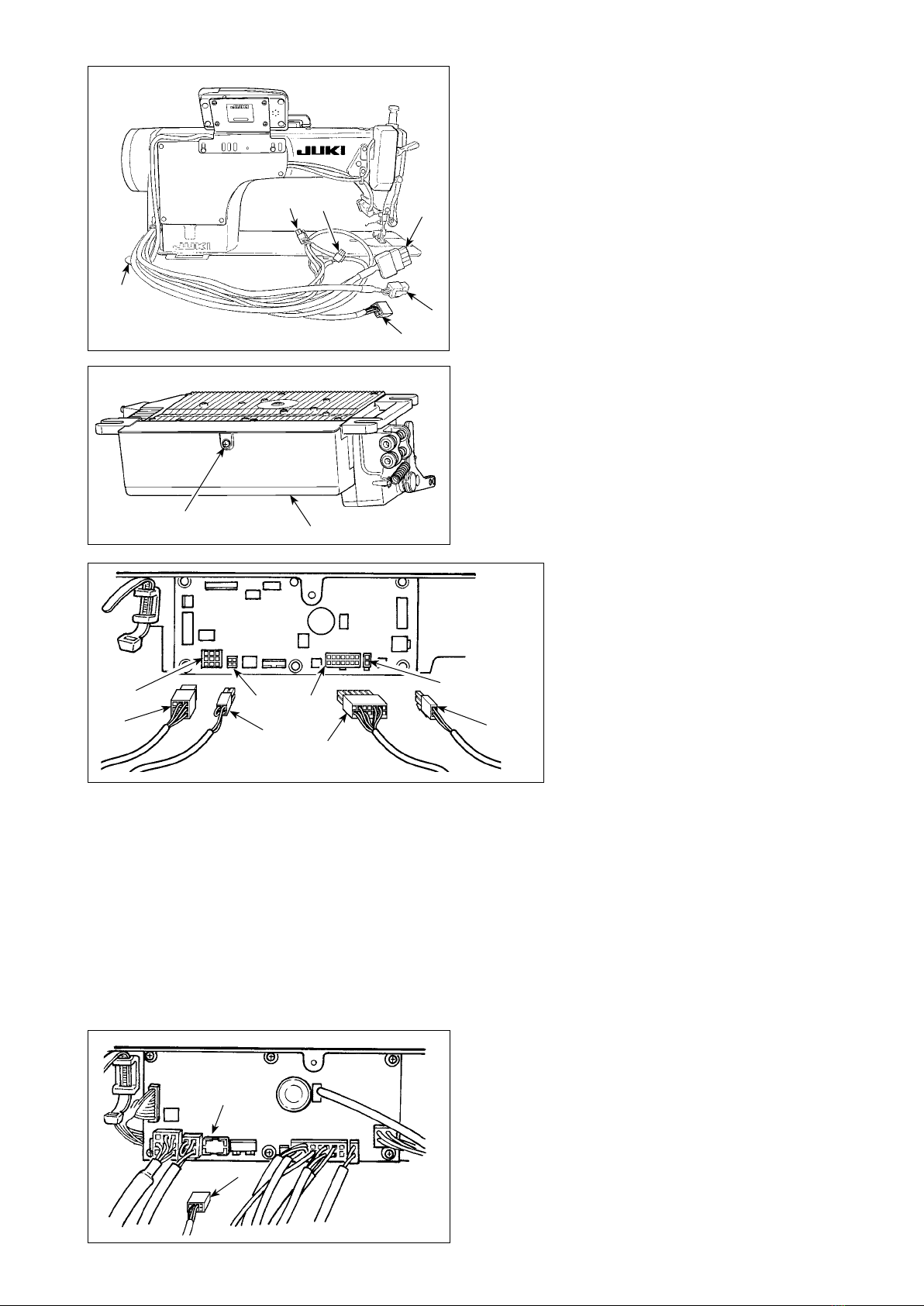

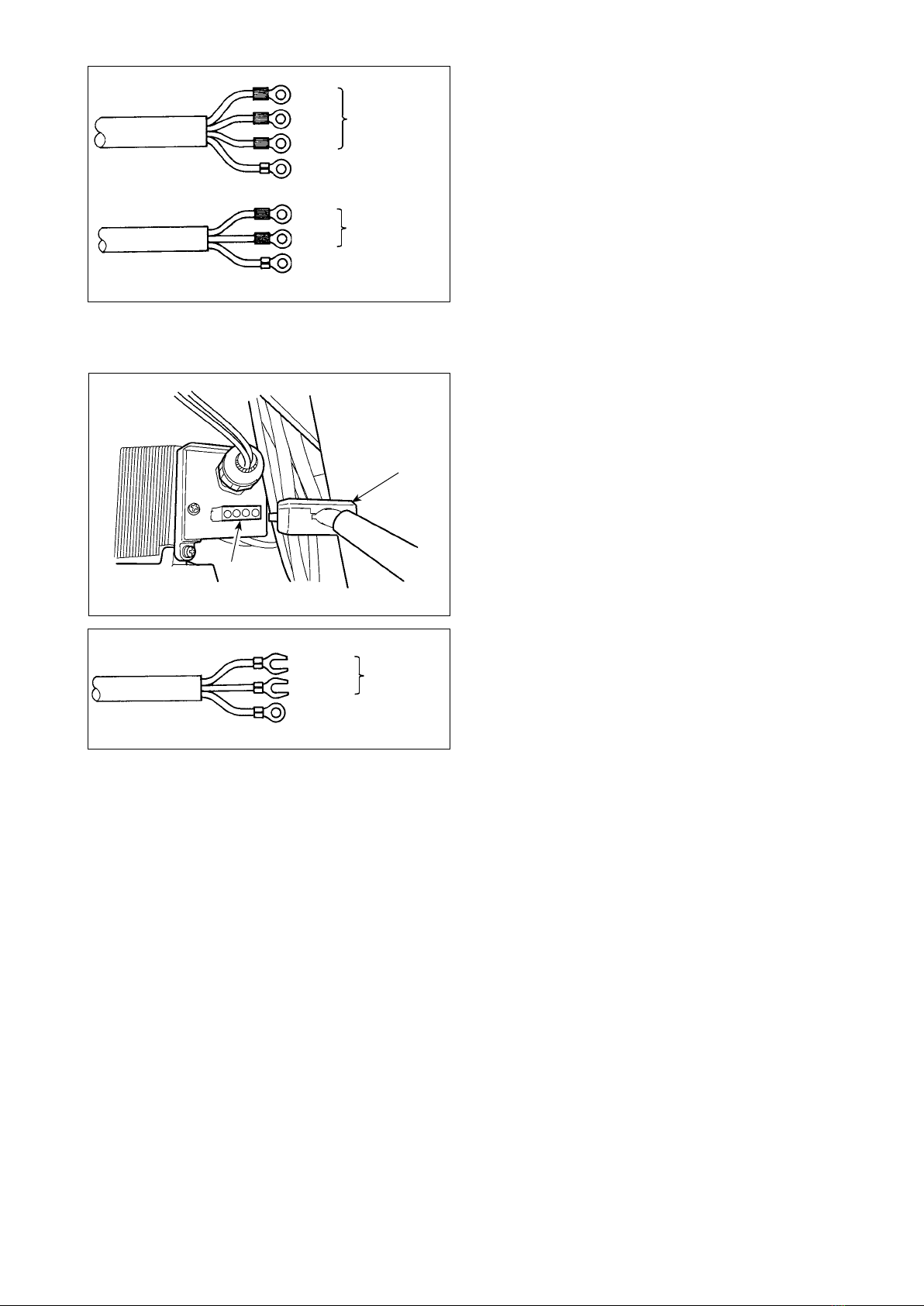

Wiring for the 3-phase 200 V

B

C

(Plug side)

WHITE

BLACK

RED

GREEN/

YELLOW

WHITE

BLACK

RED

GREEN/

YELLOW

(Plug side)

WHITE

BLACK

RED

GREEN/

YELLOW

GREEN/

YELLOW

1

2

3

WHITE

BLACK

Wiring for the single-phase 200 V

Be sure to connect the wire between 1 and 2.

If it is connected between 1-3 or 2-3, the sewing

machine will be inoperative.

(Caution)

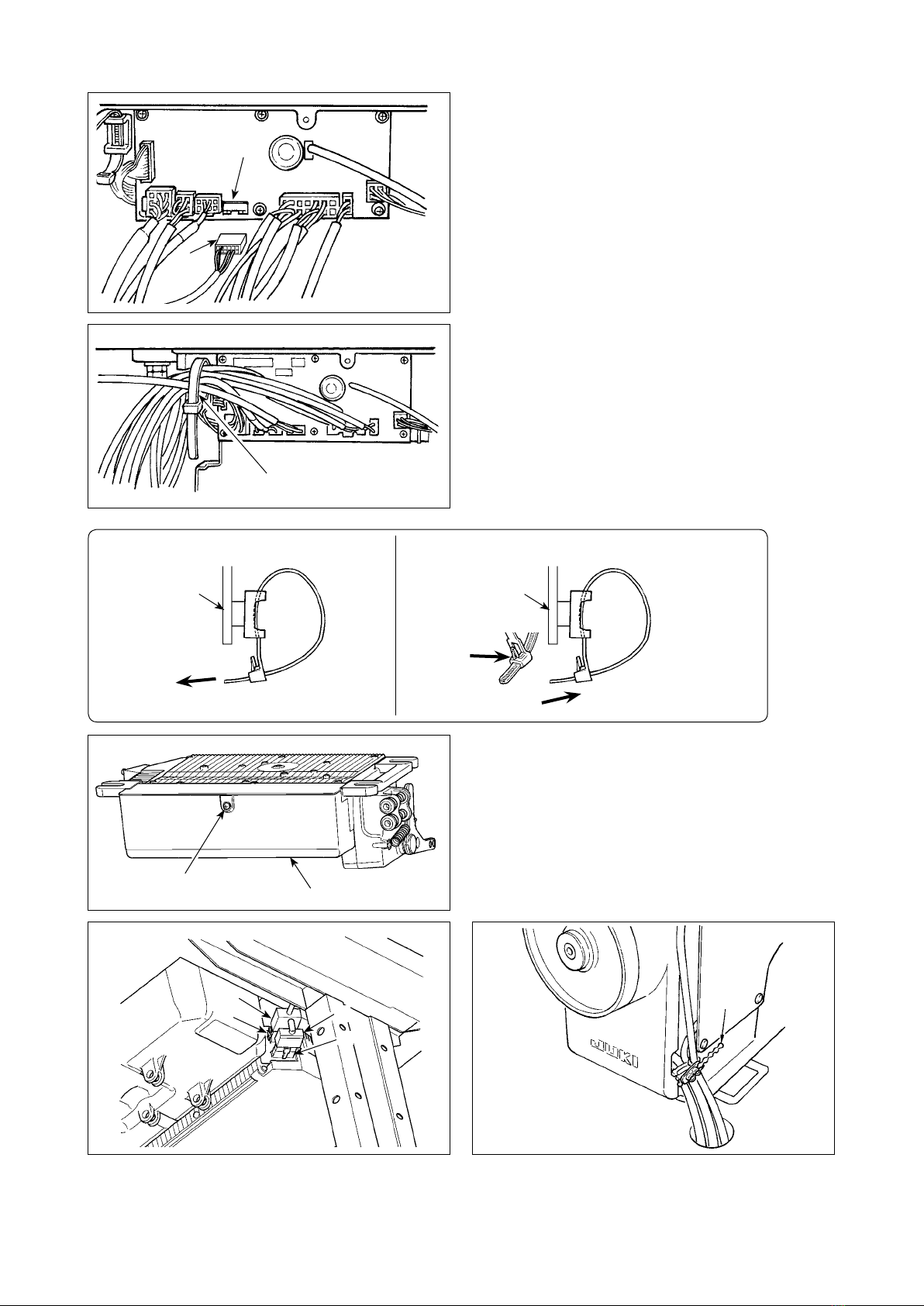

Be sure to remove the connec-

tor while holding its locking

section with your fingers. Be

extremely careful not to pull

the connector forcibly.

Locking section

(Box side)

(Box side)

Depending on specifications of the control box, the

number of phases and the voltage of the power supply

can be changed over among "single-phase 100 - 120 V,"

"single-phase 200 - 240 V" and "3-phase 200 - 240 V."

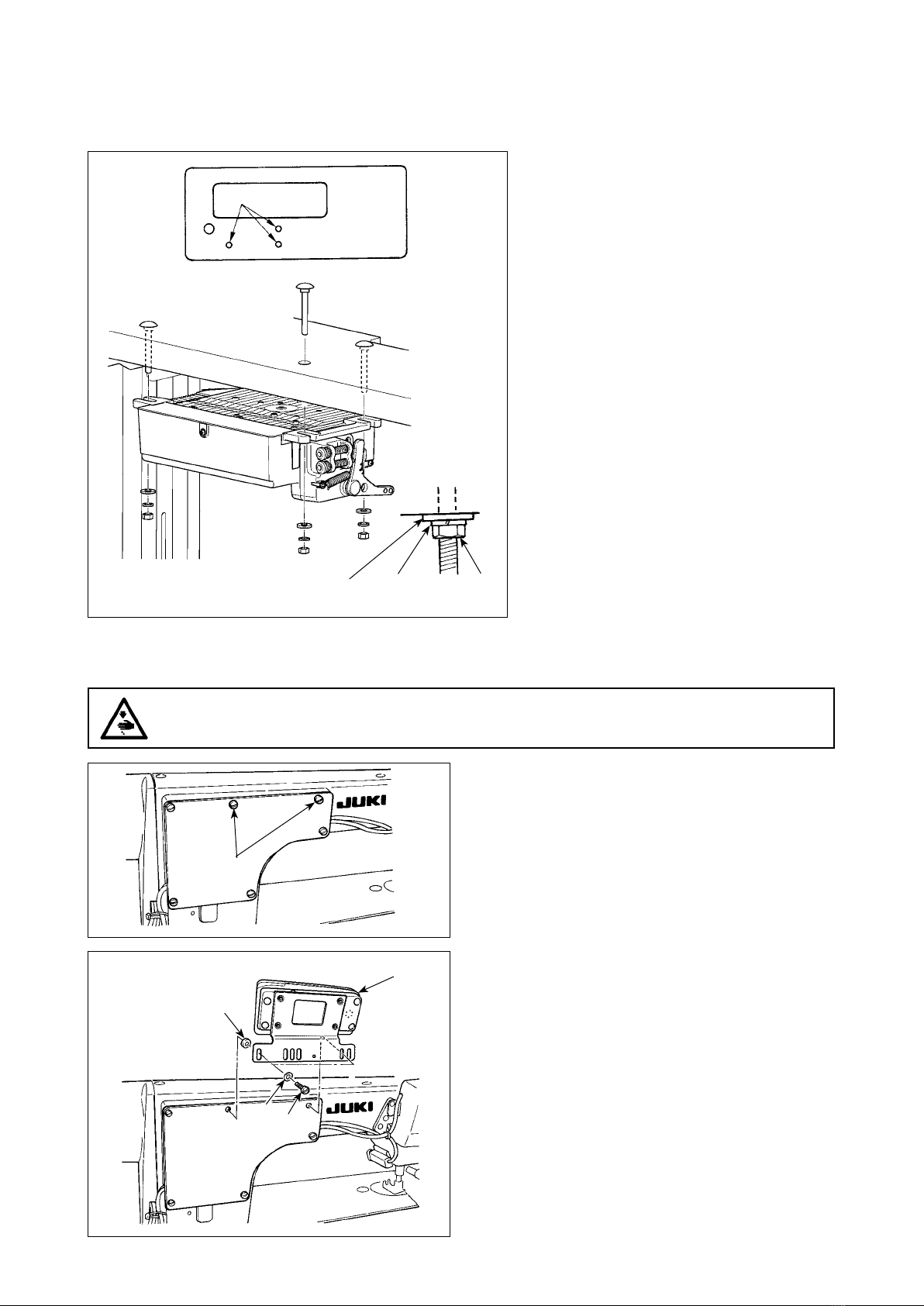

1Replacement of the power cords

2 Changing-round of connector 1 on the PWR PCB

1) Turn OFF the power with the power switch after

checking that the sewing machine has stopped.

2)

Draw out the power cord from the power receptacle

after checking that the power switch has been turned

OFF. Then wait for 5 minutes or more.

3) Loosen the screws which x the cover of the control

box. Open the cover in a slow manner.

4) Changing procedure of the power voltage

(Caution) If the supply power changing is carried out

in a wrong manner, the control box can

break. Be extremely careful when taking the

supply voltage changing procedure.

A. To change over the supply voltage from 200 -

240 V to 100 - 120 V

¡Change the power cord with the JUKI genuine

cord with the part number (M90355800A0).

Change the earth cord with the one with the part

number (M90345800A0).

¡Change over supply voltage changeover connec-

tor

1

mounted on the PWR PCB with the con-

nector for 100 V.

¡Connect the crimp style terminal of AC input cord

to the power plug as shown in the gure A.

B,C. To change over the supply voltage from 100 -

120 V to 200 - 240 V

¡Change the power cord with the JUKI genuine

cord with the part number

(M90175800A0).

¡

Change over supply voltage changeover connec-

tor

1

mounted on the PWR PCB with the con-

nector for 200 V.

¡

Connect the crimp contact of the AC input cord

to the power plug as illustrated in Fig. B for the

3-phase power supply or as illustrated in Fig. C

for the single-phase one.

5) Before closing the door, check to be sure again that

the voltage has been changed without mistake.

6) Close the back lid and secure with the screws

pressing the lid, while taking extra care to prevent

the cord from being caught between the cover and

the main body of the control box.

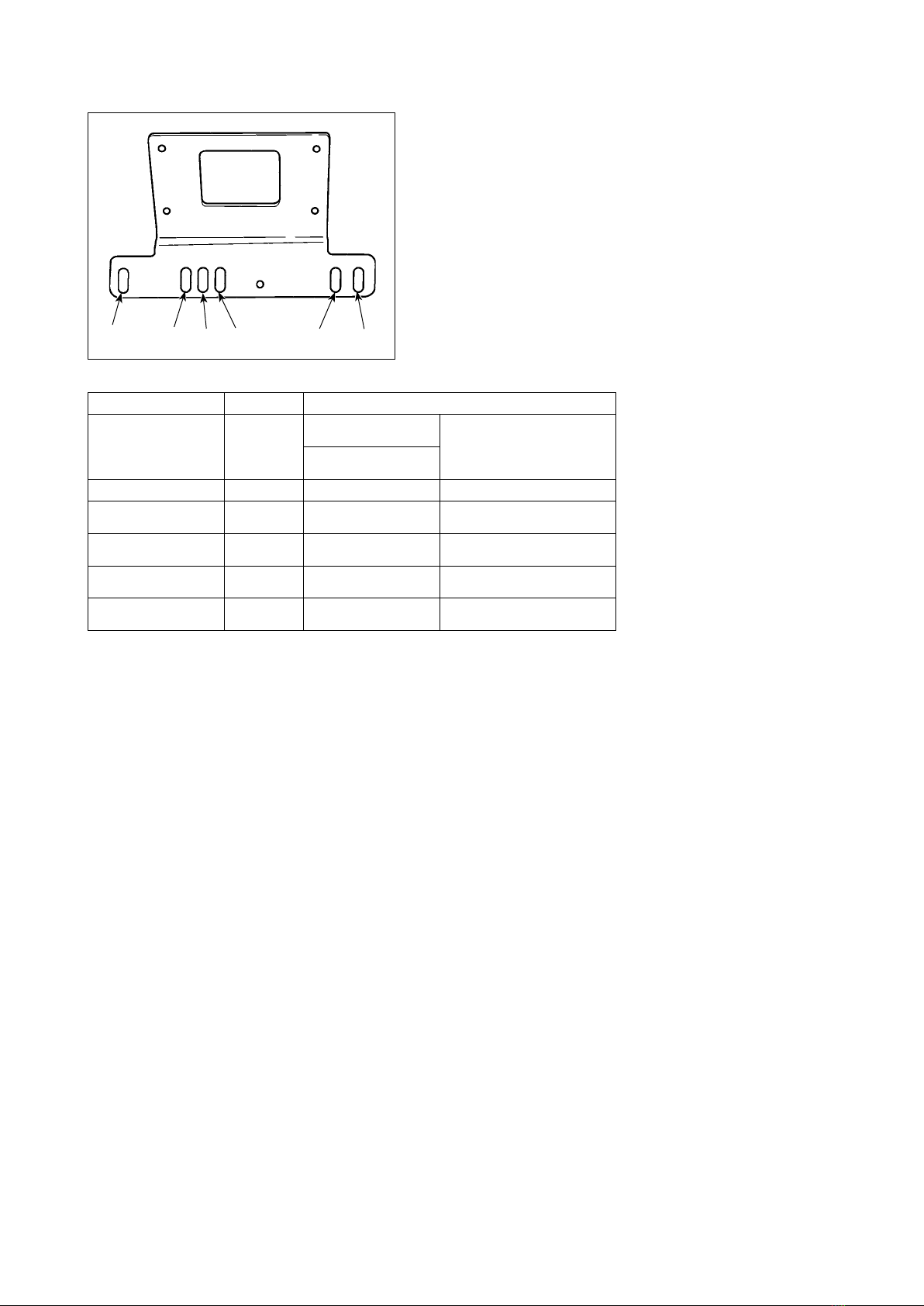

1

2

3

1. Changing over the voltage between 100 V and 200 V

WARNING :

To prevent personal injuries caused by electric shock hazards or abrupt start of the sewing machine,

carry out the work after turning OFF the power switch and a lapse of 5 minutes or more. To prevent

accidents caused by unaccustomed work or electric shock, request the electric expert or engineer of

our dealers when adjusting the electrical components.

1

A

* The illustration below shows the PWR-T PCB.

The type of PCB differs by destination.

(Plug side)

WHITE

BLACK

RED

GREEN/

YELLOW

WHITE

BLACK

GREEN/

YELLOW

Wiring for the single-phase 100 V

Be sure to connect the wire between 1 and 2.

If it is connected between 1-3 or 2-3, the sewing

machine will be inoperative.

(Box side)

1

2

3