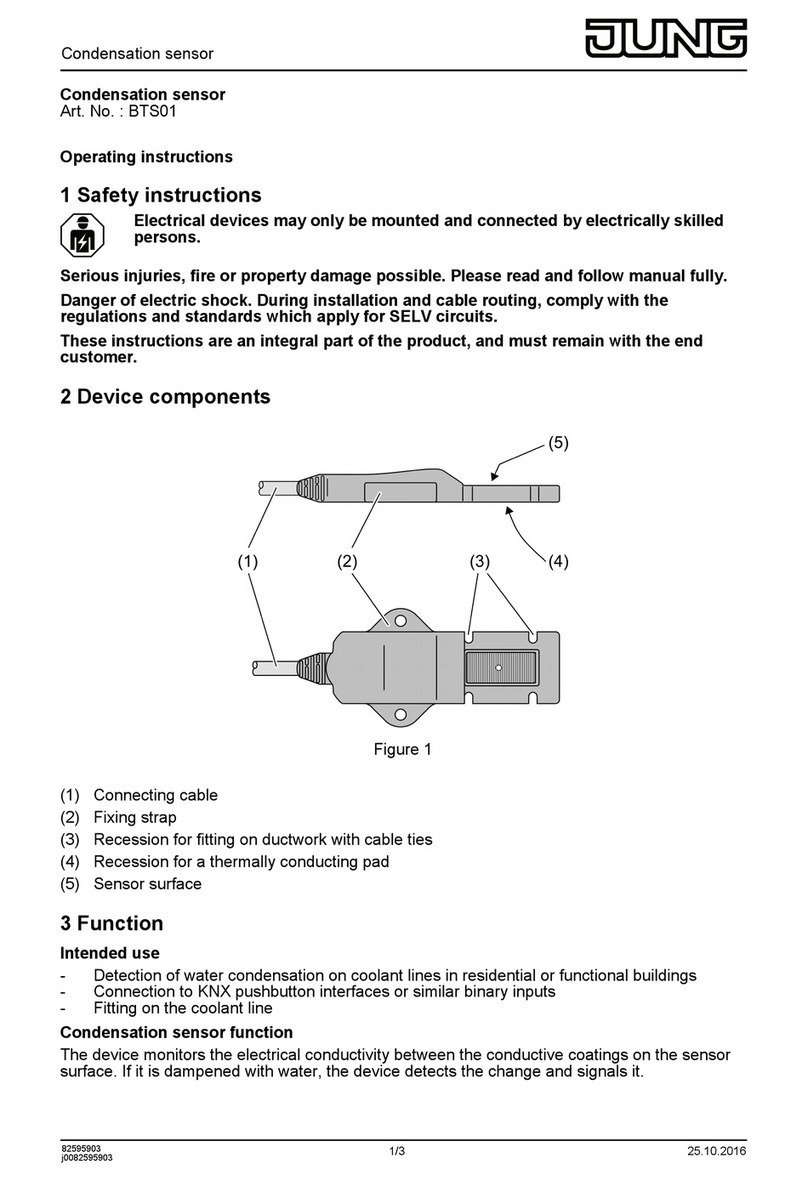

Art. No. BTS01

2.4 Commissioning and function

Commissioning of the dew sensor

The following specification must be set in the parameters of the evaluation unit (e.g. KNX valve

drive (motor-operated) with controller):

- Debounce time: 127 ms

Function of the dew sensor

The device monitors the electrical conductivity between the conductive coatings on the sensor

surface. If it is dampened with water, the device detects the change and signals it.

The device is electrically supplied by an evaluation unit. The signaling of an alarm takes place

by short-circuiting the supply voltage. The device supplies itself internally while it is short

circuited.

When the sensor surface is moistened, the device signals an alarm (rising edge) of the

evaluation unit. An internal clock measures the time beginning at this moment. The device of the

evaluation unit signals an alarm for the duration of 1 minute. The device signals an alarm as

long as the sensor surface is moistened. Even if the sensor surface is free from liquid within the

first minute, the device still signals an alarm for one minute. After the minute is up, the device

checks to see if the sensor surface is still moistened. As soon as the sensor surface is no longer

moistened, the device cancels the alarm signal (falling edge).

The signal is recorded by the KNX device used by the evaluation unit and transmitted to the

KNX in accordance with the project design. As a rule, the polarity of the KNX telegrams can be

set in the parameters of the KNX device. In accordance with the project design, "1" telegrams or

"0" telegrams are transmitted on the KNX if there is a rising or falling edge.

The device does not function in the event of prolonged supply voltage failure. The device

automatically resumes functioning upon the return of the supply voltage.

iThe device cannot prevent the accumulation of condensation, but still detects and registers

it early, so that the impact of the unwanted condensation can be kept minor.

iThe sensor surface can be damaged if it comes into contact with aggressive media (e.g.,

detergent solutions, scrubbing brines or acidic condensation from condensing boilers). The

sensor area is to be checked after every alarm. The device is to be exchanged in the event

of significant damage from corrosion.

Page 9 of 17

Mounting, electrical connection and operation