KS-FX222

1-8 (No.49772)

2.2 Cassette mechanism assembly

• Prior to performing the following procedures, remove the head

amplifier board, the relay board and the mechanism bracket.

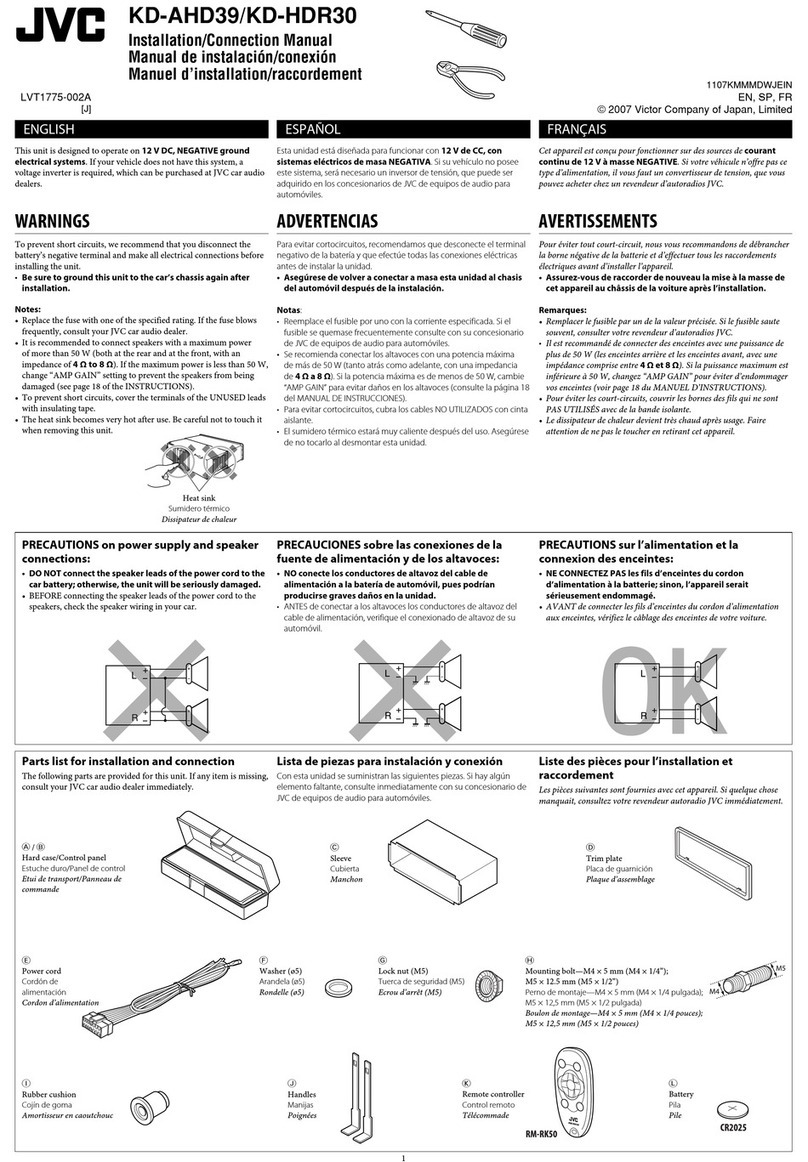

2.2.1 Removing the direction switch board

(See Fig.1)

(1) Unsolder the three wires aon the direction switch board.

(2) Remove the one screw Aattaching the direction switch

board.

2.2.2 Removing the FF / REW lever assembly

(See Fig.1)

(1) Remove the screw Battaching the FF / REW lever assem-

bly on the back of the cassette mechanism assembly.

(2) Remove the screw Con the upper side of the FF / REW

lever assembly.

(3) Lift and pull forward the FF / REW lever assembly to disen-

gage the joints b, c, dand e.

2.2.3 Reattaching the FF / REW lever assembly

(See Fig.1)

(1) Reattach the FF / REW lever assembly to the joint con the

back of the chassis.

(2) Reattach the pinch-roller shaft e, the change lever dand

the return link eto the chassis.

Fig.1

2.2.4 Removing the playback head

(See Fig.2)

• Prior to performing the following procedure, remove the direc-

tion switch board and the FF / REW lever assembly.

(1) Remove the screw Dattaching the playback head.

(2) Remove the Cwasher and pull out the FF roller.

(3) Remove the Ssupport plate, the A arm spring (a) and (b),

the playback head.

ATTENTION:

The A arm spring (a) differs from the A arm spring (b).

2.2.5 Removing the pinch-roller (R) and (F) assembly

(See Fig.2)

• Prior to performing the following procedure, remove the direc-

tion switch board and the FF / REW lever assembly.

(1) Remove the P arm spring (f) in the pinch-roller (F) assem-

bly from the chassis.

(2) Remove the P arm spring (r) in the pinch-roller (R) assem-

bly from the chassis.

(3) Draw out the pinch roller (F) and (R) assembly from the

shaft.

ATTENTION:

The P arm spring (f) differs from the P arm spring (r).

ATTENTION:

The pinch roller (F) assembly differs from the pinch roller (R)

assembly.

Fig.2

C

FF / REW lever assembly

Joint c

Joint b

B

A

Direction switch board

Joint d

Joint e

Soldering a

A arm spring (b) A arm spring (a)

Pinch-roller (R) assembly Pinch-roller (F) assembly

Shaft Shaft

S support plate

D

C washer

P arm spring (f)

P arm spring (r)

Remove the P arm spring (f)

from the chassis.

Remove the P arm spring (r)

from the chassis.

Playback head

FF roller

w

w

w

.

x

i

a

o

y

u

1

6

3

.

c

o

m

Q

Q

3

7

6

3

1

5

1

5

0

9

9

2

8

9

4

2

9

8

T

E

L

1

3

9

4

2

2

9

6

5

1

3

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

http://www.xiaoyu163.com