3

GENERAL SAFETY INFORMATION

1.Ensurethat attachments are fully engaged before

applyingload.

2. Ensure that load is centrally applied to attachment

or ram saddle. Do not load off center.

3.Always monitor the force applied to workpiece by

using a load cell and indicator or you may monitor

pressure developed in the ram by using an inline

pressuregauge, then calculate the applied force

usingthe formula:

F = P x A, where F = lbs force, P = pressure in PSI,

andA = effective ram area in in².

RamArea of KTI-63705 is: 0.998 in²

RamArea of KTI-63711 is: 2.431 in²

4. If bowing or bending of ram or any attachment

occurs during use, "STOP",release pressure

immediatelyand reconsider application.Application

may not be compatible with product, a ram kit with

a higher capacity may be needed.

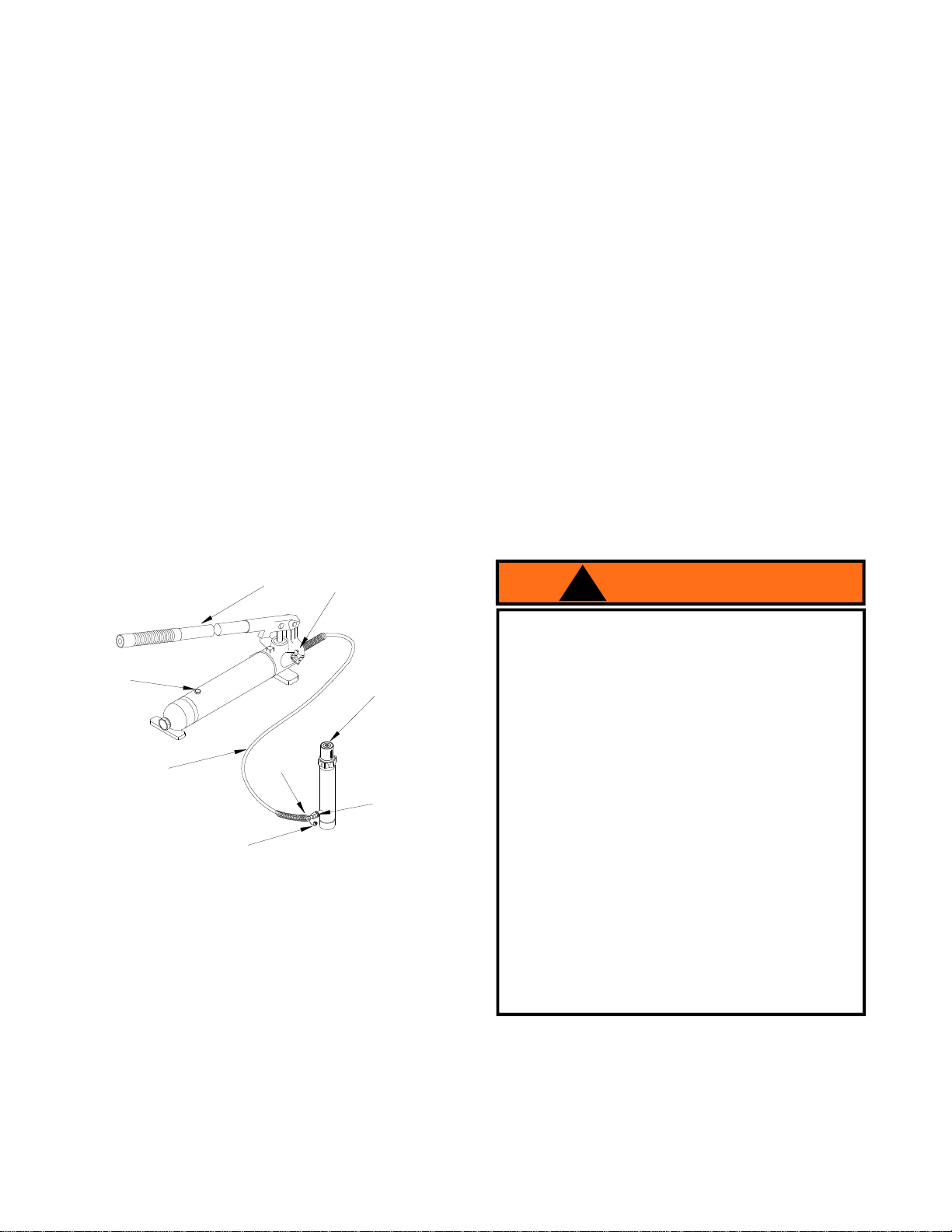

BEFORE USE (refer to Figure 1)

1. Inspect before each use. Do not use if bent,

broken, leaking or damaged components are noted.

2. Ensure that product and application are compatible.

3. Check to ensure that all parts of your kit are

included (see illustration and parts list).

4.Carefully remove the dust caps and plugs from hose

couplerand ram coupler.

5. Connect hose coupler to ram coupler, ensure that

there are no fluid leaks.

6.Locate and open releasevalve. Pump handle afew

strokes to purge air from system. Close release

valveand pump handle until ram is fully extended,

thenopen release valve until ramhasfully retracted.

7. With pump in normal, horizontal position, locate and

open oil filler screw (located centrally on reservoir

body). This will aid in the release of air trapped

withinthereservoir.Retighten the oil filler screw.

8. If using air actuated units, an air source of at least

7.8 CFM @ 90psi is required.

•Study, understand, and follow all instructions

provided with and on this device before use.

•Do not exceed rated capacity.

• Useonly on hard, level surfaces capable of

sustaining rated capacity loads.

•Do not open oil filler screw unless ram is fully

retracted.

•Always wear safety glasses when using this

equipment.

•Do not use as a vehicle lifting device or as a

vehiclesupport.

•When extension tubes and/or offset attachments

are used, the rated capacity is always reduced

by 50% for each tube or attachment connected.

•Any attachment that is not loaded centrally, as

through the centerline of the ram, is considered to

be "offset". See parts section for identification of

offsetatachments.

•Do not modify this device.

•Failure to heed these markings may result in

personalinjury and/or property damage.

WARNING

!

Figure 1- KTI-63705 and KTI-63711 Nomenclature

Dust Cover

Oil Filler

Screw

Handle Release Valve

Ram Plunger

Hose Hose

Coupler

Ram Coupler

KTI-63705-M0