D

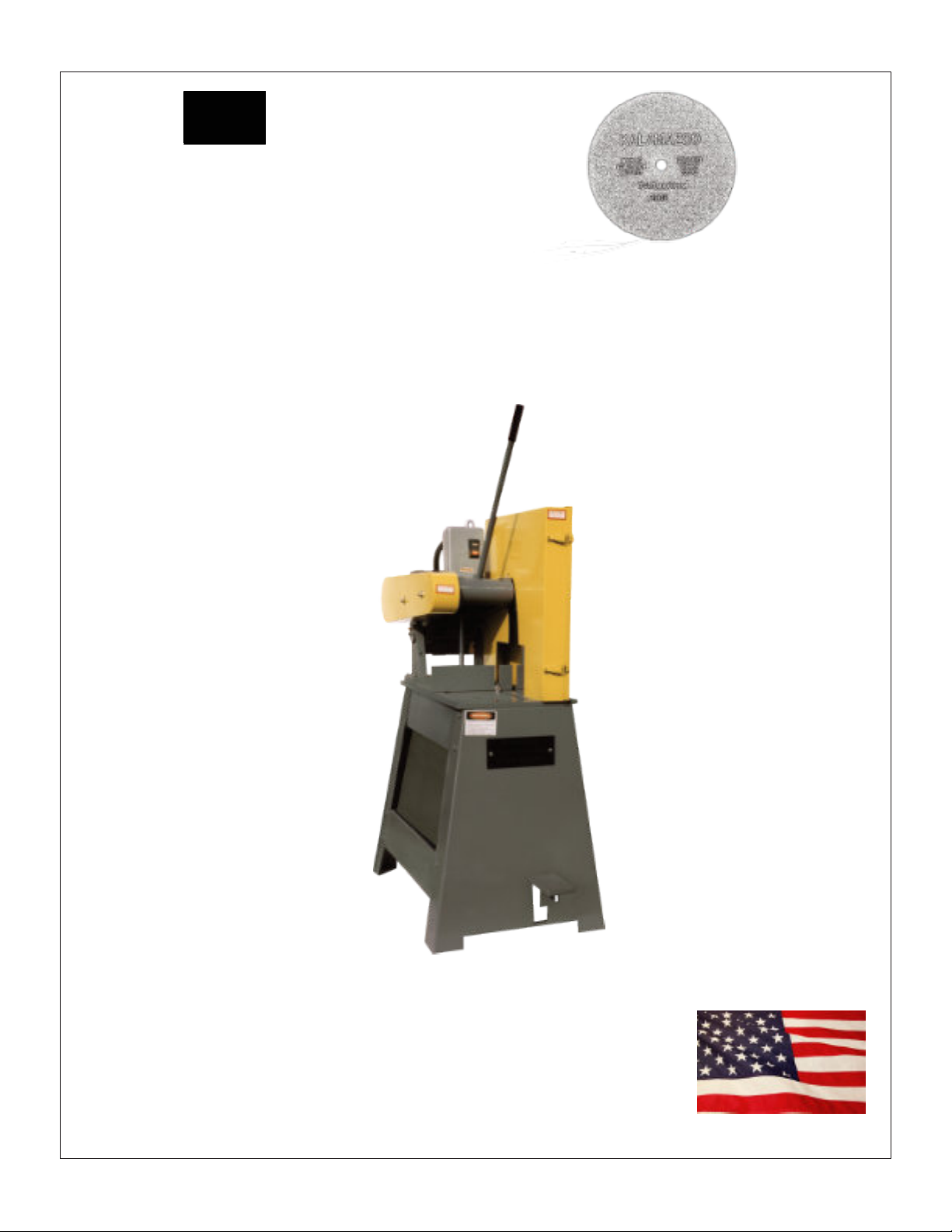

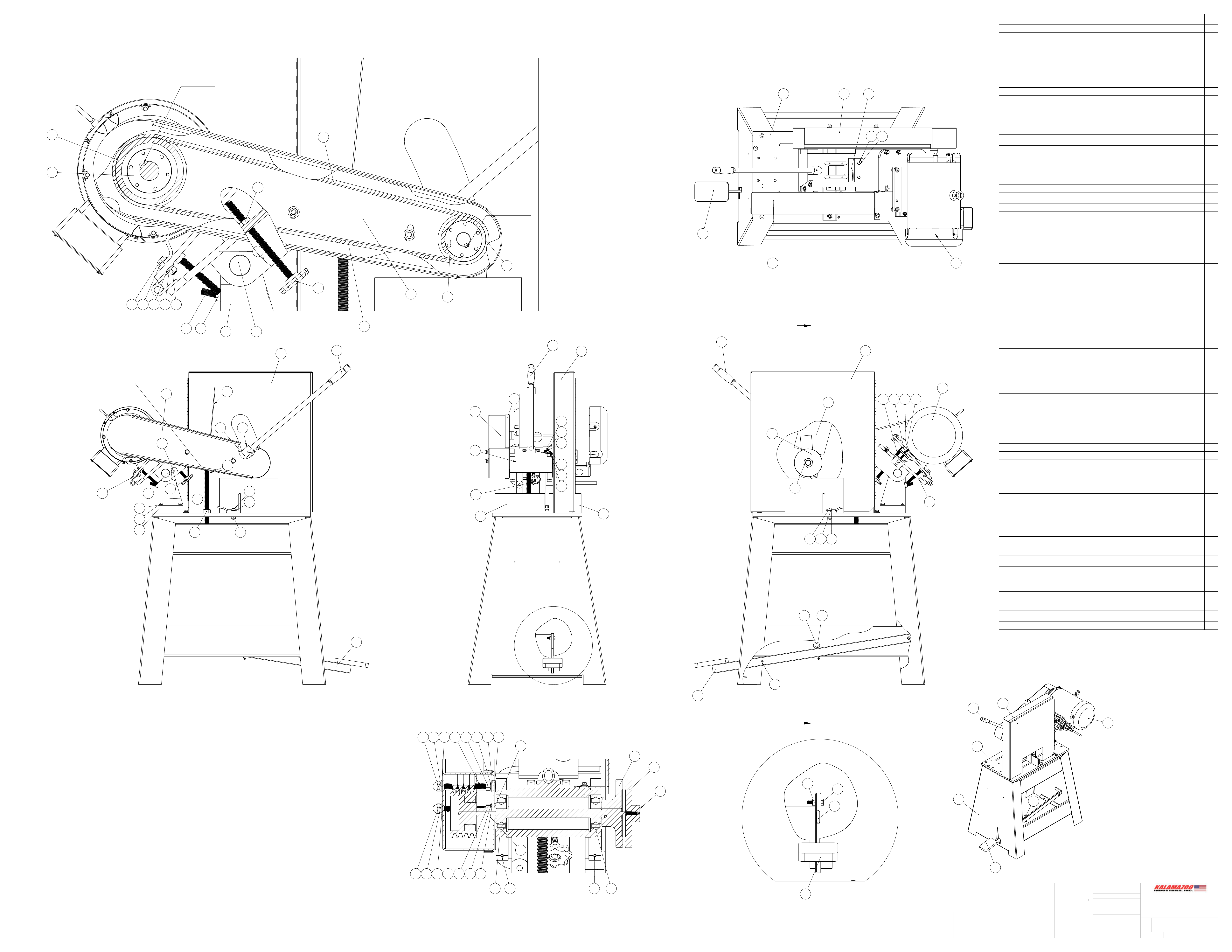

FRONT VIEW

40

46

18

38 37

33

36

10

48

49

50

48

49

50

1

51

53

24

46

40

2

LEFT SIDE VIEW

46 40

18

9

7

8

4

5

X 4 PLACES

33

16

10 41

51

44

X 2 PLACES

STOP HEIGHT IS ADJUSTABLE

54

55

59

60

4

39

X 2 PLACES

A

A

RIGHT SIDE VIEW

24

40

46

35 5 4

X 2 PLACES

16

20 21 22 23

45

13

14

51

53 42

43

LOCATION

LOCATION

25

26

27

28

17 4 4 5 6

X 4 PLACES

97

30

36

30

X 4 BELTS

16

19

18

1/4SQ X 2 KEY

1/4 SQ X 1-1/4 KEY

57 58

DETAIL D

SCALE 2 : 5

51

53

52

23

SECTION A-A

SCALE 1 : 2

INTERNAL SPINDLE VIEW

34 5 4 32 6 5 4 4

56

11 15 15 11

12

13

14

34 5 4 31 6 5 4

29

332

51

24

48 49

59

X 2 PLACES

46

TOP VIEW

ITEM

NO.

PART NUMBER

DESCRIPTION

QTY.

1

716-023

STAND ASSEMBLY FOR K16-18

1

2

050-018A

BASE, PLATE K16-18 (NEW STYLE AFTER

08/20/2014)

1

3

FSCA037020

3/8-16 X 1-1/4 FSHCS

4

4

UFWZ037

3/8 USS F/W Z

34

5

SLWZ037

3/8 SPLIT L/W Z

28

6

FHN5037

3/8-16 FHN GR5 Z

12

7

831-021

TRUNNION FOR KM16-18, K16-18, K20SSF

(NEW STYLE)

1

8

HHC5037036

3/8-16 X 2-1/4 HHCS GR 5 Z

4

9

700-003

NEW STYLE TRUNNION PIN FOR K16-18, KM

STYLE TRUNNION, K20SSF

1

10

002-005

SAW ARM FOR K16-18, KM16-18, AND K20SSF

SAW

1

11

044-004

K20 SPINDLE BEARING

2

12

701-010

SPINDLE W TIGHT FLANGE FOR K16-18,

K20SSF, K20E SAWS

1

13

292-011

LOOSE FLANGE FOR K16-20, KM16-18, KM20-

22 1

14

537-027

SPINDLE NUT FOR K16-20

1

15

SSKA031006

5/16-18 X 3/8 SOC SET KNURL PT.

2

16

486-010

MOTOR MOUNT PLATE FOR K16-20 ASSEMBLY

1

17

HHC5037020

3/8-16 X 1-1/4 HHCS GR5 Z

8

18

696-029

MOTOR PLATE TENSION SCREW FOR K16-K20

SAWS

1

19

FJNZ050

1/2-13 F H JAM NUT Z

1

20

CRBZ031040

5/16-18 X 2-1/2 CARRIAGE BOLT Z

1

21

UFWZ031

5/16 USS F/W Z

1

22

SLWZ031 5/16 SPLIT L/W Z

1

23

FHN5031

5/16-18 FHN GR5 ZINC

2

24

486-019

10HP MOTOR FOR K16-18, KM16-18, BG14

1

25

560-046

MOTOR PULLEY SHEAVE FOR K16-18, KM16-

18, K20SSF-15, KM20-22/15, KM20-22W/15

(K20SSF 7 1/2 HP), SPINDLE PULLEY SHEAVE

FOR K20SW-15HP & 20HP

1

26

049-003

MOTOR PULLEY BUSHING FOR FOR K16-18,

KM16-18, K20SSF-15, K20RS-15, K20SW-15,

KM20-22-15HP, KM20-22W-15

FOR K16-18, KM16-18, K20SSF-15, K20RS-15,

K20SW-15,

KM20-22-15HP, KM20-22W-15

1

27

560-047

SPINDLE PULLEY SHEAVE FOR K16-18, KM16-

18, K20SSF-15, K20RS, KM20-22/15, MOTOR

PULLEY SHEAVE FOR K20SW-20HP

1

28

049-004

SPINDLE PULLEY BUSHING FOR K16-18, K20SSF-

15HP, K20RS-15

KM16-18, KM20-22-15HP

1

29

RND-3/4CFC1018X7/8

7/8 INCHES OF RND-3/4 CF C1018

1

30

051-005

V-BELT FOR K16-18, K20SSF, K20E,

K20RS, K20SW

4

31

RND-3/8-16THRDRODX6.25

6-1/4 INCHES OF RND-3/8-16 THREADED ROD

1

32

RND-3/8-16THRDRODX5.375

5-3/8 INCHES OF RND- 3/8-16 THREADED ROD

1

33

342-039

OUTER GUARD, BELT FOR K16-18 AND K20SSF

SAWS

1

34

CPNZ037

3/8-16 CAP NUT NICKEL

2

35

SHCA037020

3/8-16 X 1-1/4 SHCS

2

36

342-039A

GUARD, INNER BELT FOR K16-18, KM16-18,

K20SSF SAWS

1

37

293-003

FENCE, RIGHT FOR K16-18, K20SSF

1

38

293-002

FENCE, LEFT FOR K16-18, K20SSF

1

39

SHCA037024

3/8-16 X 1-1/2 SHCS

2

40

381-009

HANDLE WITH GRIP FOR K16-20 ABRASIVE

SAW

1

41

SSKA025006

1/4-20 X 3/8 SOC SET KNURL PT.

1

42

697-021

SPRING FOR HOOK CHAIN ASSY FOR K16-18

AND K20SSF CHAIN VISE

1

43

697-022

SPRING, FOOT PEDAL FOR K16-18 AND

K20SSF SAWS

1

44

ZERK012000

1/8-27 X 11/16 STRT LUBE FITTING

2

45

342-030

INNER WHEEL GUARD FOR K16-18, K20SSF

SAWS

1

46

342-014

WHEEL GUARD FOR K16-18 SAW

1

47

HHC5037016

3/8-16 X 1 HHCS GR5 Z

4

48

HHC5025008

1/4-20 X 1/2 HHCS GR5 Z

4

49

SLWZ025

1/4 SPLIT L/W Z

4

50

UFWZ025

1/4 USS F/W Z

2

51

041-007

Default

1

52

HHC5031020

5/16-18 X 1-1/4 HHCS GR 5 Z

1

53

TEBZ031032

5/16X2 TURNED EYE BOLT Z

1

54

709-003

STOP, DOWN FOR K16-18 AND K20SSF SAWS

1

55

FHN5075

3/4-10 FHN GR5 Z

1

56

049-116

SPACER BUSHING FOR K20 SERIES SPINDLE

1

57

RND-1/2-13THRDRODX2

2 INCHES OF RND-1/2-13 THREADED ROD

1

58

FHN5050

1/2-13 FHN GR5 Z

1

59

041-092

SWITCH BRACKET FOR MAG SWITCH ON K20

ARM

1

60

537-007

LONG FENCE NUT FOR K16-20 SAWS

1

A A

B B

C C

D D

E E

F F

G G

H H

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

K16-18 CUT-OFF

SAW

DO NOT SCALE DRAWING

K16-18

SHEET 1 OF 1

UNLESS OTHERWISE SPECIFIED:

SCALE: 1:5

WEIGHT:

REV

DWG. NO.

E

SIZE

TITLE:

NAME

DATE

COMMENTS:

Q.A.

MFG APPR.

ENG APPR.

CHECKED

DRAWN

FINISH

MATERIAL

INTERPRET GEOMETRIC

TOLERANCING PER:

DIMENSIONS ARE IN INCHES

TOLERANCES:

FRACTIONAL

ANGULAR: MACH

BEND

TWO PLACE DECIMAL

THREE PLACE DECIMAL

APPLICATION

USED ON

NEXT ASSY

PROPRIETARYAND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

<INSERT COMPANY NAME HERE>. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

<INSERT COMPANY NAME HERE> IS

PROHIBITED.