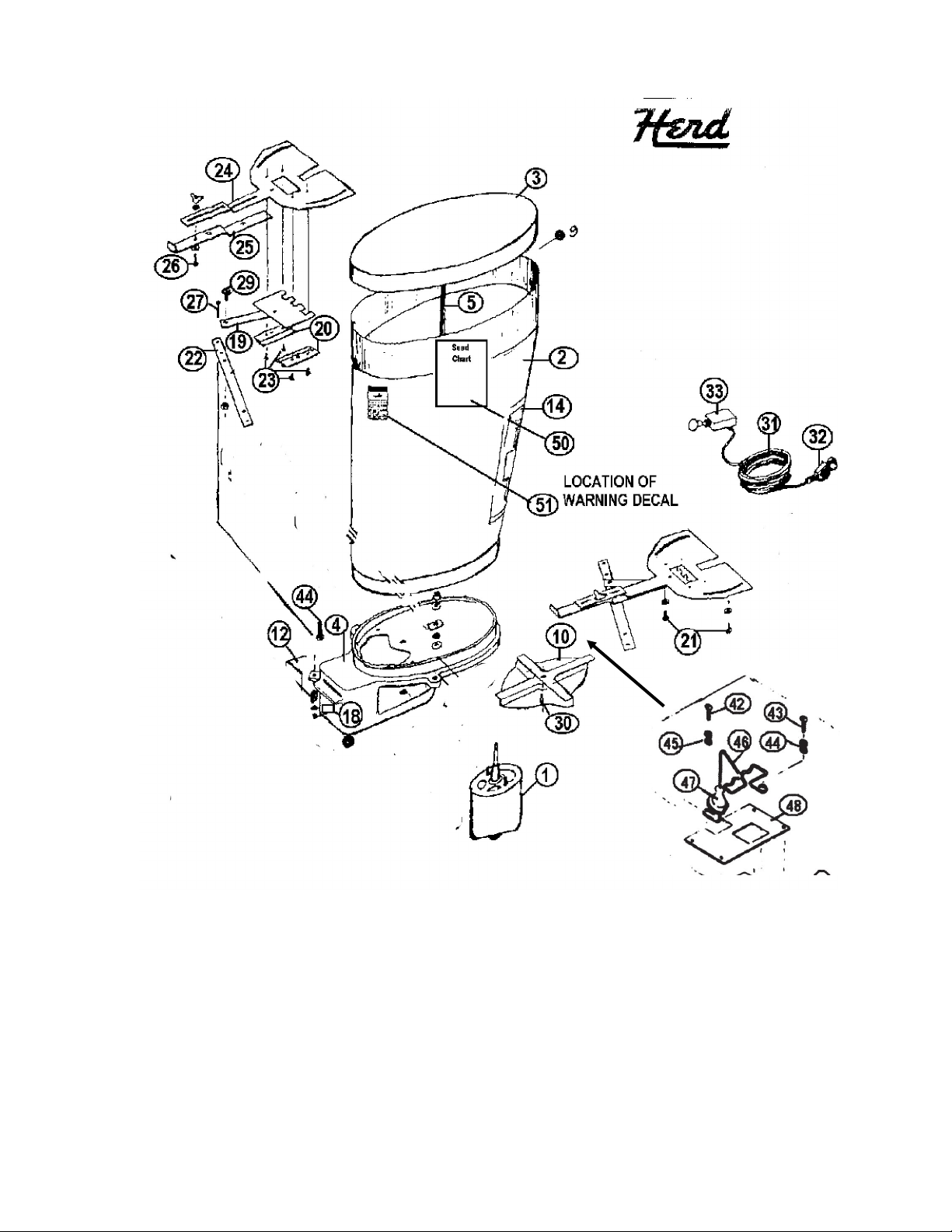

MODEL I-258 General Instructions

1. For Normal broadcasting of seeds, this model I-258 seeder requires no changes. It was

assembled at the factory for this purpose.

2. This model may be mounted via one of our mounting kits (i.e. #660 2” receiver hitch, Carton

JPH-1, etc).

3. An electronic speed control (#812) may be purchased as an option to control the width of

the spread of material. This will allow the spread pattern to be narrowed by a slower fan

speed.

4. To center the spread pattern, pivot plate #802SI can be rotated left or right. To do this,

loosen the two capscrews holding the pivot plate to the base of the seeder. While facing the

hopper and looking at the Herd Seeder Co. decal, if the spread pattern of the material being

spread is heavy to your right, then move the pivot plate to a lower letter. If the spread

pattern of the material is heavy to the left, move the pivot plate to a higher letter.

5. Be sure the battery charge is up and the generator/alternator is operating efficiently, so that

the broadcaster will operate at the necessary RPMs. The motor will use approximately 8 to

10 amps when spreading.

6. This unit is not recommended for fertilizer or salt as the corrosive material must be kept off

the electric motor.

ASSEMBLY INSTRUCTIONS

1. Place the broadcaster motor side up, on a level surface for assembly.

2. Turn the handle (part #729) around toward the seeder base and remove the flathead screw

and jamnut. Place flathead screw first through the hole in the seed gate linkage, then

through the hole in the handle. Tighten with the jam nut until snug. Make sure the jam nut is

up, facing you, and not too tight, as it must pivot at this point.

3. Check the opening gauge control plate (part #803S) for correct fit. It is possible the gauge

could have been bent in shipping. This gauge is used to set the seed gate opening opening

width to regulate the amount of seed flowing through the seed gate onto the spinner fan.

The seeder is now ready to be mounted.

MOUNTING #794 SWITCH

1. The push-pull switch (part #794) can be mounted next to the driver’s seat, in a convenient

spot. It can also be mounted next to the broadcaster on one of the remaining holes on the

cross angle iron.

2. When the optional #811 Electronic Speed Control is used, FOLLOW THE INSTRUCTIONS

SUPPLIED WITH THE #811 KIT EXACTLY. Failure to follow instructions exactly will result

in motor failure and will void the warranty.

WIRING INSTRUCTIONS

1. Run the #754 wire from the motor terminal to the switch or rheostat, then run a wire from

the switch or rheostat to the positive (+) battery terminal. Use 14 gauge wire or heavier.

2. You can use the battery clamp #755 to connect the positive (+) wire from the switch or

rheostat to the positive (+) battery terminal for convenience.

3. A second ground must be run between the frame of the seeder and the frame of the

vehicle.