Zennio ZN1DI-RGBX4 User manual

Other Zennio Controllers manuals

Zennio

Zennio ZCL-8HT230 Guide

Zennio

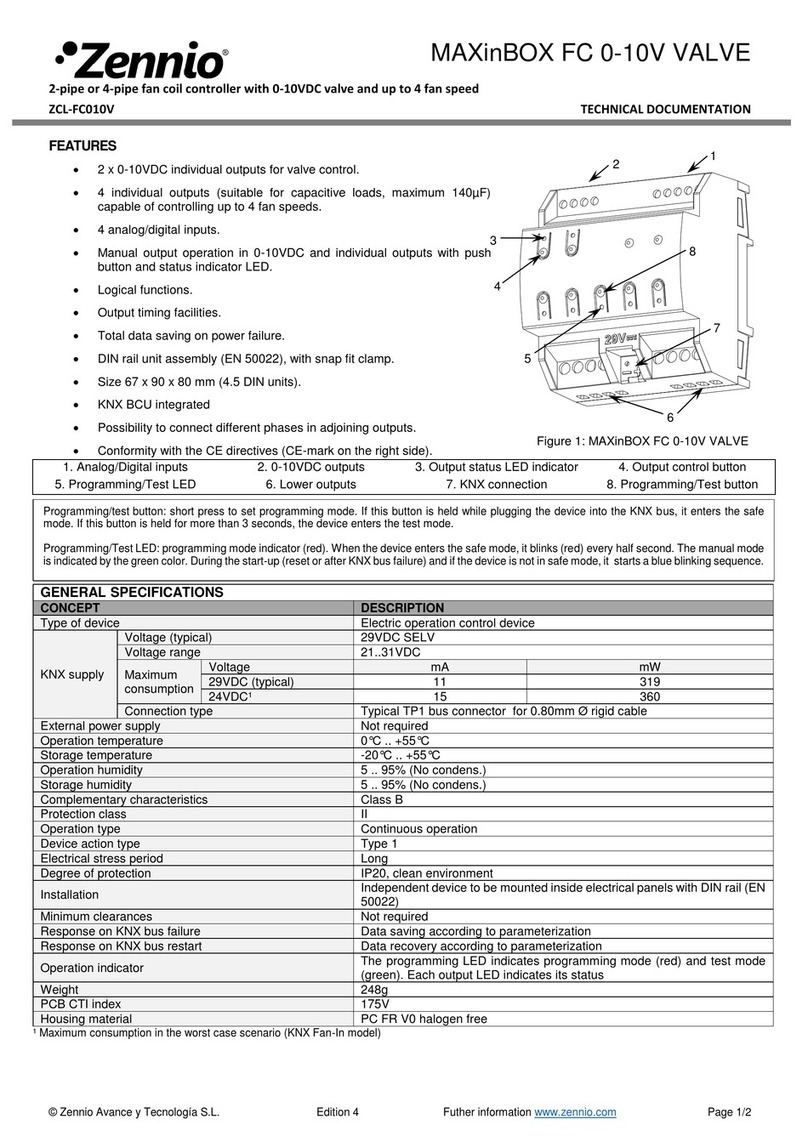

Zennio MAXinBOX FC 0-10V FAN Guide

Zennio

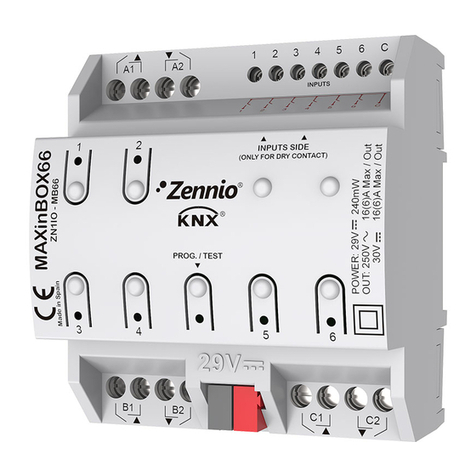

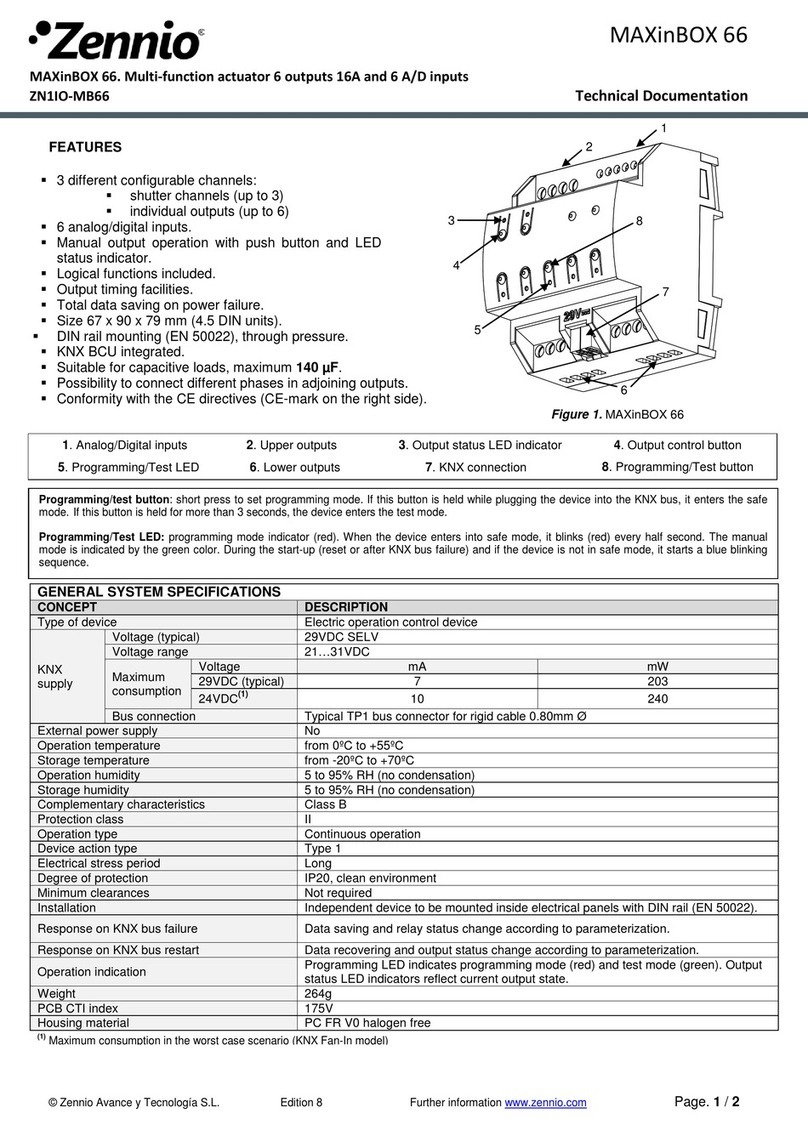

Zennio MAXinBOX66 Guide

Zennio

Zennio MAXinBOX FC 0-10V VALVE User manual

Zennio

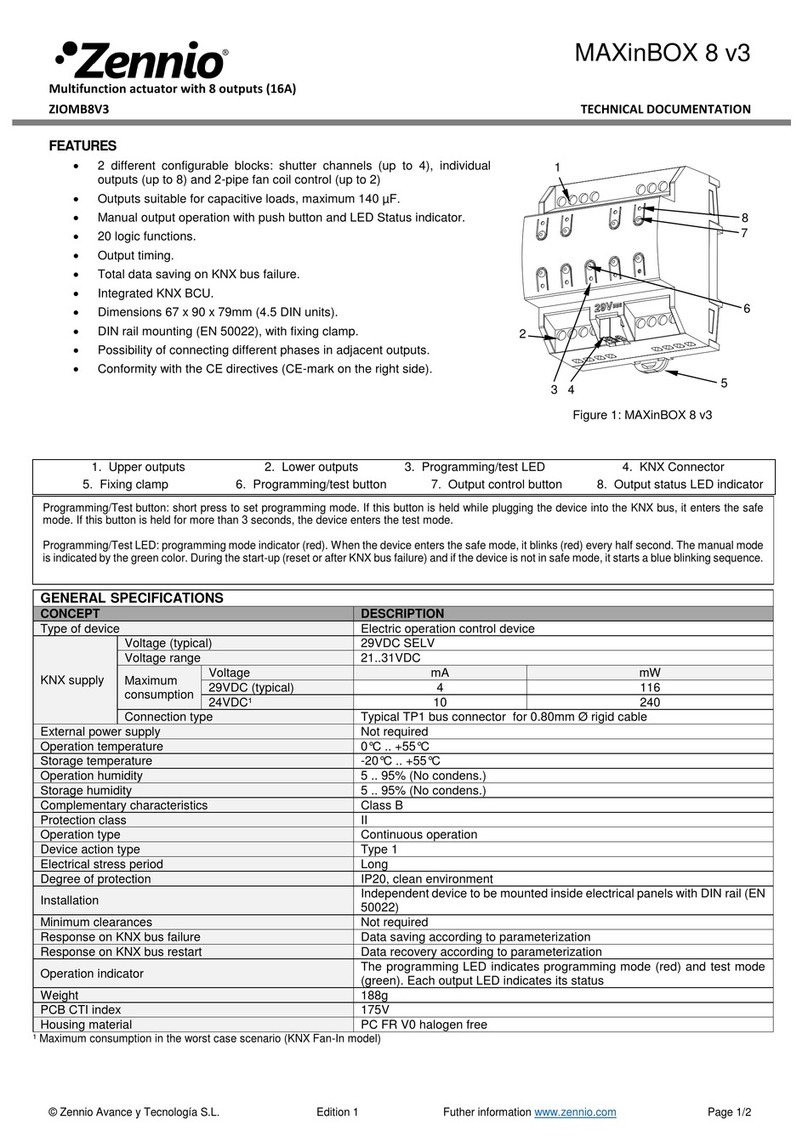

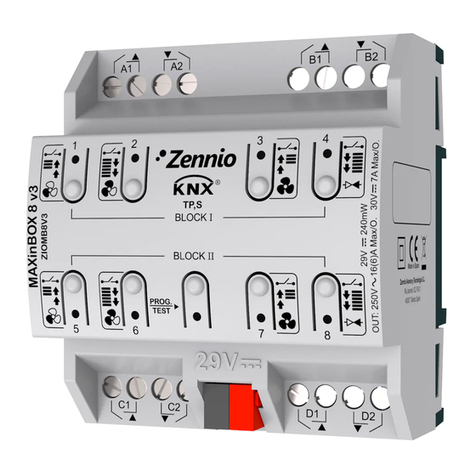

Zennio MAXinBOX 8 v3 Guide

Zennio

Zennio Tecla 55 User manual

Zennio

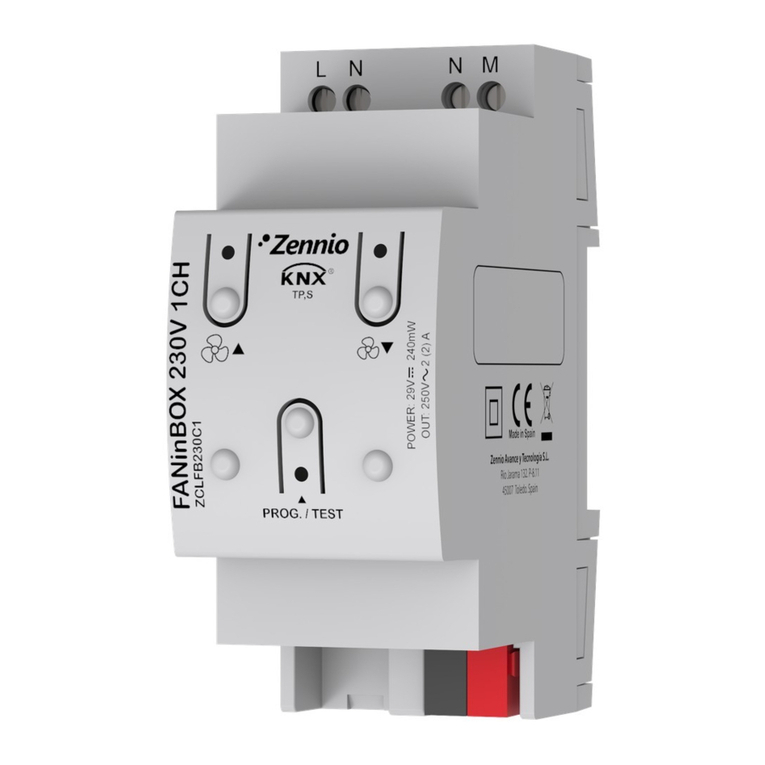

Zennio FANinBOX 230V 1CH Guide

Zennio

Zennio LUMENTO X4 Guide

Zennio

Zennio MINiBOX 25 Guide

Zennio

Zennio ALLinBOX 1612 Guide

Zennio

Zennio ZCL-MCC User manual

Zennio

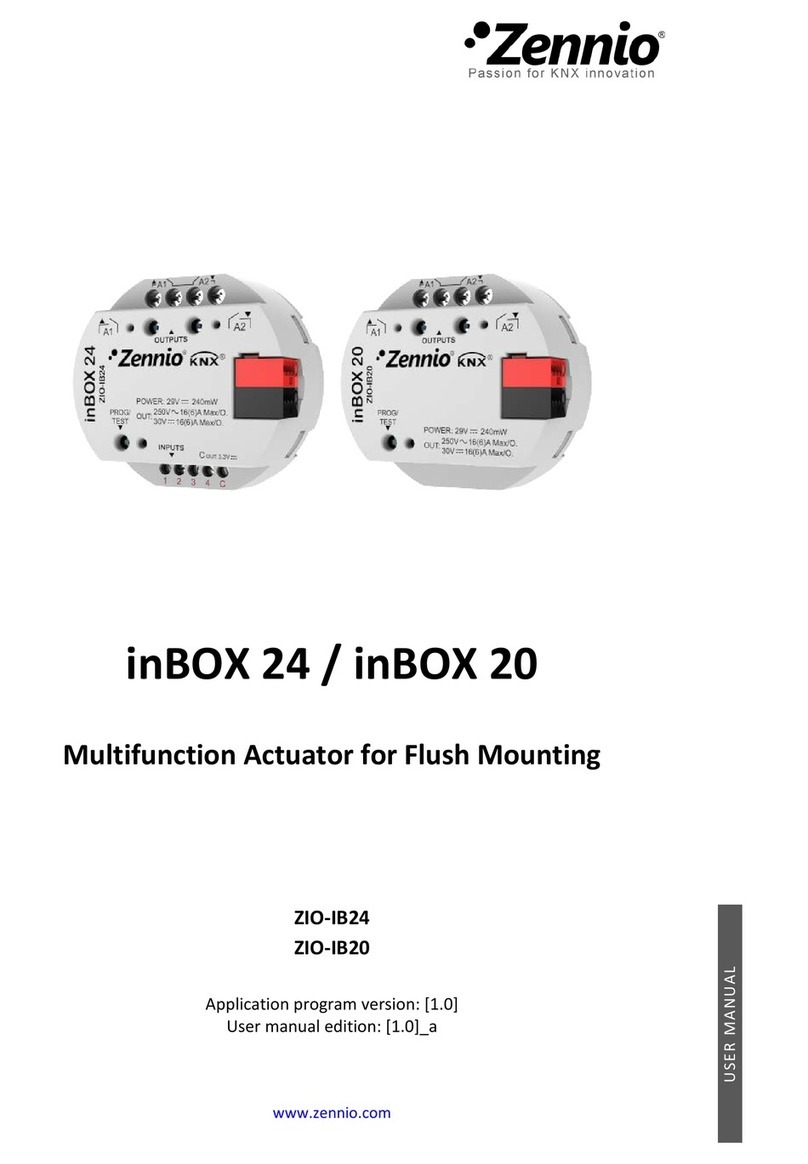

Zennio ZIO-IB24 User manual

Zennio

Zennio IRSC Plus User manual

Zennio

Zennio MAXinBOX FC 0-10V VALVE User manual

Zennio

Zennio MAXinBOX FANCOIL 2CH2P User manual

Zennio

Zennio MINiBOX 20 User manual

Zennio

Zennio MAXinBOX 66 Guide

Zennio

Zennio Tecla 55 X Sign User manual

Zennio

Zennio Roll-ZAS User manual

Zennio

Zennio MAXinBOX 8 Plus Guide

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions