GB - 3

1. Introduction......................................................................................................................4

1.1 Preface............................................................................................................................................... 4

1.2 Product description.......................................................................................................................... 4

1.3 Speciedapplication........................................................................................................................ 5

1.3.1 Standard operation ............................................................................................................................. 5

1.3.2 Abnormal operation............................................................................................................................. 5

1.4 Unitidentication.............................................................................................................................. 5

2. Safety Instructions ..........................................................................................................6

2.1 General instructions......................................................................................................................... 6

2.2 Transport, Storage and Installation................................................................................................. 6

2.3 Electrical connection........................................................................................................................ 7

2.4 EMC instructions ............................................................................................................................ 10

2.5 EMC conform installation............................................................................................................... 10

3. Technical Data ...............................................................................................................11

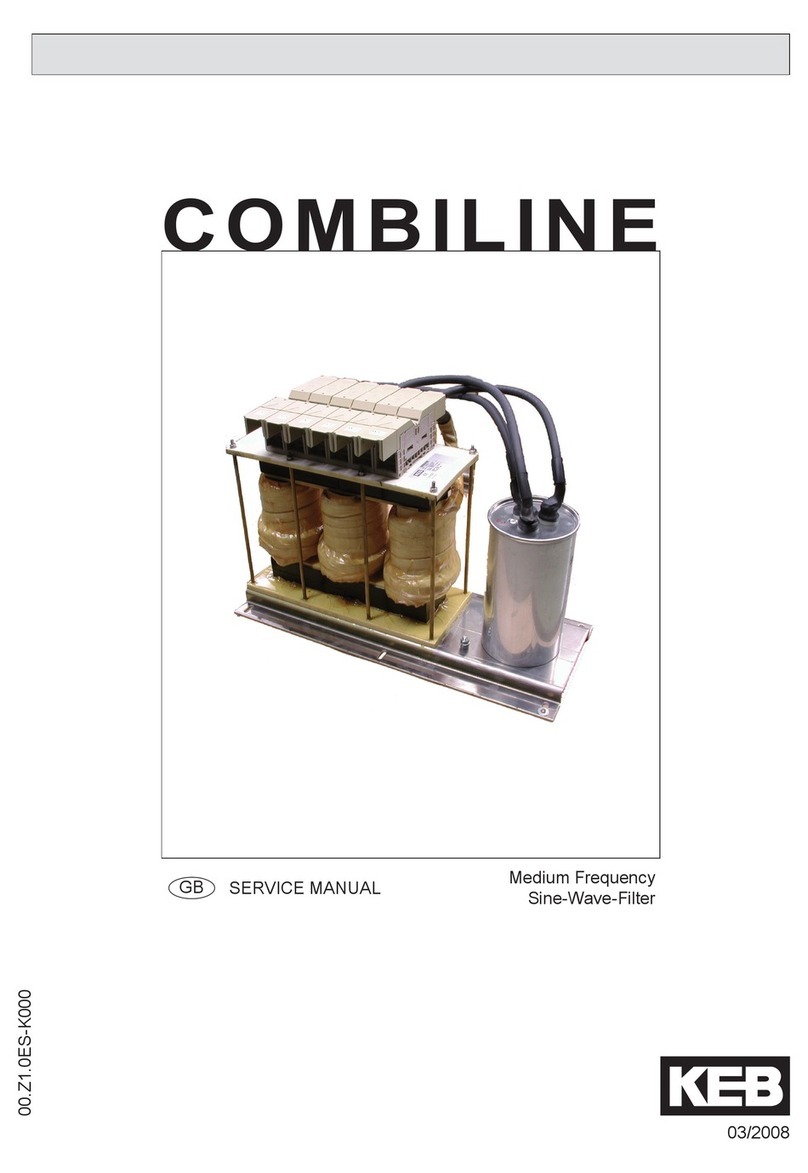

3.1 Power data........................................................................................................................................11

3.2 Operating conditions...................................................................................................................... 12

3.3 Accessories..................................................................................................................................... 12

3.4 Options ............................................................................................................................................ 13

3.5 Dimensions and weights................................................................................................................ 13

3.5.1 COMBIVERT R6-S ........................................................................................................................... 13

3.5.2 Commutation throttle......................................................................................................................... 14

3.5.3 HFsub-mountinglter....................................................................................................................... 14

3.5.4 Ferrite rings....................................................................................................................................... 14

4. Installation......................................................................................................................15

4.1 EMC-compatible control cabinet installation............................................................................... 15

4.2 Installation instructions ................................................................................................................. 15

4.3 Connection of the COMBIVERT R6 ............................................................................................... 16

4.3.1 Connection terminals of the power circuit......................................................................................... 16

4.3.2 Connection terminals of the commutation throttle............................................................................. 16

4.4 Connection power circuit R6-S with internal fuses..................................................................... 17

4.4.1 Powersupplyandregenerativeoperationatinvertercurrent≤currentofoneCOMBIVERTR6-S . 17

4.4.2 Powersupplyandregenrativeoperationatinvertercurrents≤currentofoneCOMBIVERTR6-S.. 17

4.4.3 Powersupplyandregenrativeoperationatinvertercurrents≥currentofoneCOMBIVERTR6-S.. 18

4.4.4 Power supply and regenerative operation with contactor circuit....................................................... 19

4.4.5 Regenerative operation with decoupling diodes ............................................................................... 20

4.4.6 Power supply /regenerative operation at parallel operation of COMBIVERT R6-S with recovery

contactor........................................................................................................................................... 21

4.4.7 Regenerative operation at parallel operation of COMBIVERT R6-S with decoupling diodes ........... 22

4.5 Connection of the control board version S.................................................................................. 23

4.5.1 Assignment of the control terminal strip X2A.................................................................................... 23

4.5.2 Assignment of socket X2B................................................................................................................ 23

4.5.3 Wiring example ................................................................................................................................. 24

4.6 Operator........................................................................................................................................... 25

5. Operation of the Unit.....................................................................................................26

5.1 Keyboard ......................................................................................................................................... 26

5.2 Operation with PC und system software COMBIVIS ................................................................... 26

5.3 Switch-on procedure ...................................................................................................................... 26

5.4 Parameter summary ....................................................................................................................... 28

5.5 Password input ............................................................................................................................... 29

5.6 Monitoring- and analysis parameters ........................................................................................... 29

5.7 Special adjustments ....................................................................................................................... 33

A. Appendix ........................................................................................................................36

A.1 Dimensioning of power supply and regenerative units .............................................................. 36

A.2 DC link capacitors of KEB frequency inverters ........................................................................... 37

A.3 Dimensioning of decoupling diodes............................................................................................. 37

Table of Contents