PAGE 2 OF 3 0515 IH-2108

NOTE: The end user is responsible for ensuring

that all employees involved in the operation

of this hopper understand and follow these

instructions!

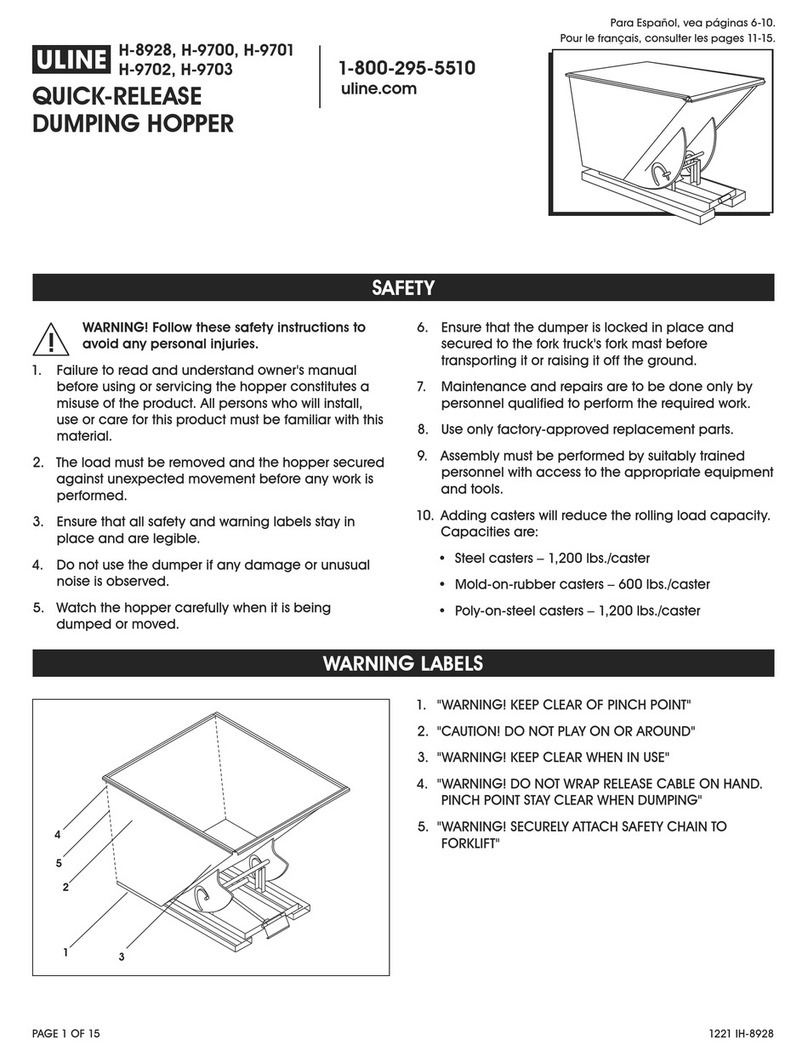

Self-dumping hoppers are suitable for use indoors and

outdoors in most common industrial and commercial

locations. They are intended to be used in conjunction

with a rider fork truck to dump non-hazardous refuse into

typical refuse containers.

Dumper is a self-dumping hopper having a 70° dump

angle. It is operated by a release cable held by the fork

truck driver.

NOTE: OSHA 29CFR, Chapter XVII, Part 1910.178

(a)(4) states, “Modifications and additions

which affect capacity and safe operation (of

a fork truck) shall not be performed by the

customer or user without manufacturer’s prior

written approval. Capacity, operation and

maintenance instruction plates, tags or decals

shall be changed accordingly. And 1910.178

(a)(5) states that “If (a fork) truck is equipped

with front-end attachments other than factory

installed attachments, the user shall request

that the truck be marked to identify the

attachments and show the approximate weight

of the truck and attachment combination

at maximum elevation with load laterally

centered.”

LOADING

The load rating, in pounds, is shown on the dumper’s ca-

pacity label located on the rear (fork truck side) of the

hopper.

WARNING! To avoid the risk of sustaining

serious personal injuries:

• Verify that the dumper is locked in the fully

upright position before loading the hopper.

• Do not exceed the dumper’s (and if portable,

its casters’) load ratings or fill the hopper

above the top of the hopper’s sides. Injury

to personnel or permanent damage to the

equipment could result from overloading.

OPERATION

WARNING! To minimize the risk to yourself and

others, always carefully watch the hopper and

its load when transporting or emptying it.

1. From the rear of the dumper, insert the fork truck’s

forks into the dumper’s fork pockets. The fork truck’s

forks are to be inserted completely.

2. Secure the dumper to the fork truck’s fork carriage

with the attached safety restraint. Wrap the restraint

around a part of the fork carriage and attach the

chain’s snap hook to the chain (through one of the

chain links) with as little slack as possible.

3. Place the release cable within reach of the fork

truck driver in preparation for dumping.

4. Move the front of the dumper into position at the

side of the dumpster or refuse container.

5. Lift and tilt the fork truck mast forward until the

dumper is at the appropriate height to allow the

front of its frame to make contact with the top of the

container’s side.

NOTE: Allow clearance for the hopper to

completely rotate forward without contacting

any obstructions.

WARNING! Keep all personnel clear of the

dumper and the dumping area before

releasing the hopper.

6. The release cable can be pulled from the fork truck

operator’s position.

WARNING! Never wrap the dumper’s release

cable around any body part.

7. Tilt the fork truck mast back, then back away from

the refuse container and slowly lower the dumper.

Dumper will automatically rotate backward and

lock in the upright position.

WARNING! Never use the dumper if any

damage or unusual motion is observed, if

it is in need of repairs, or if it seems to be

malfunctioning.

Notify your supervisor or maintenance personnel if you

notice anything out of the ordinary.

Ensure all safety and warning labels stay in place and

are legible. Refer to the warning labels section.

OPERATION